An Overview of Fine Wire Staples

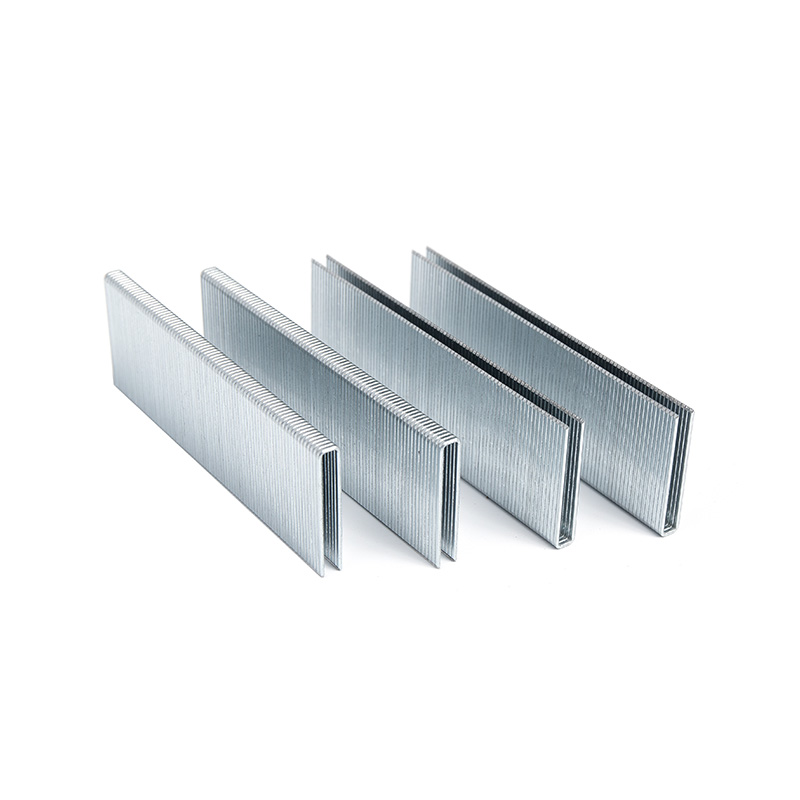

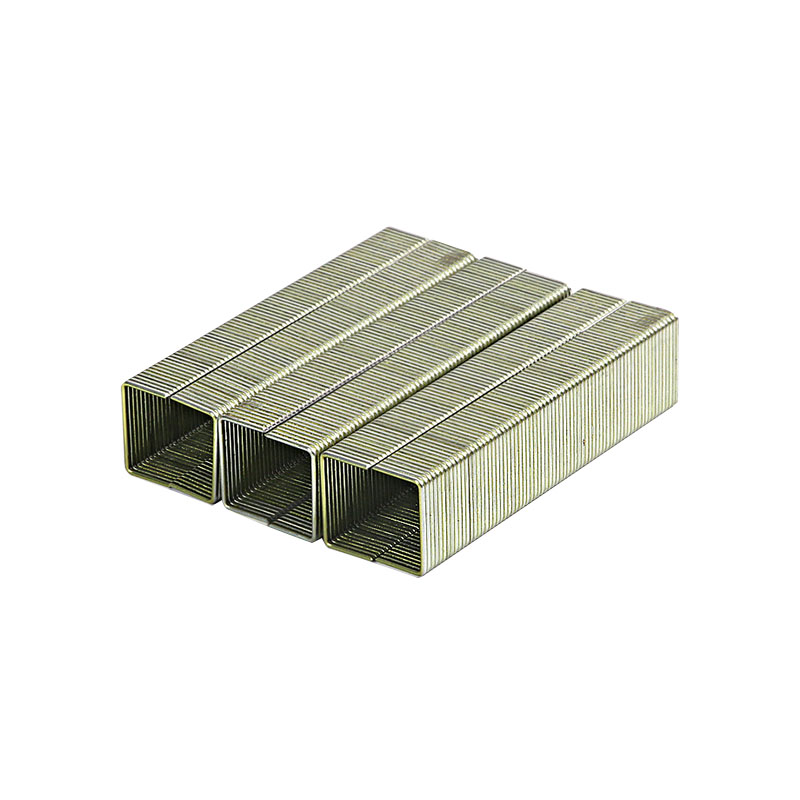

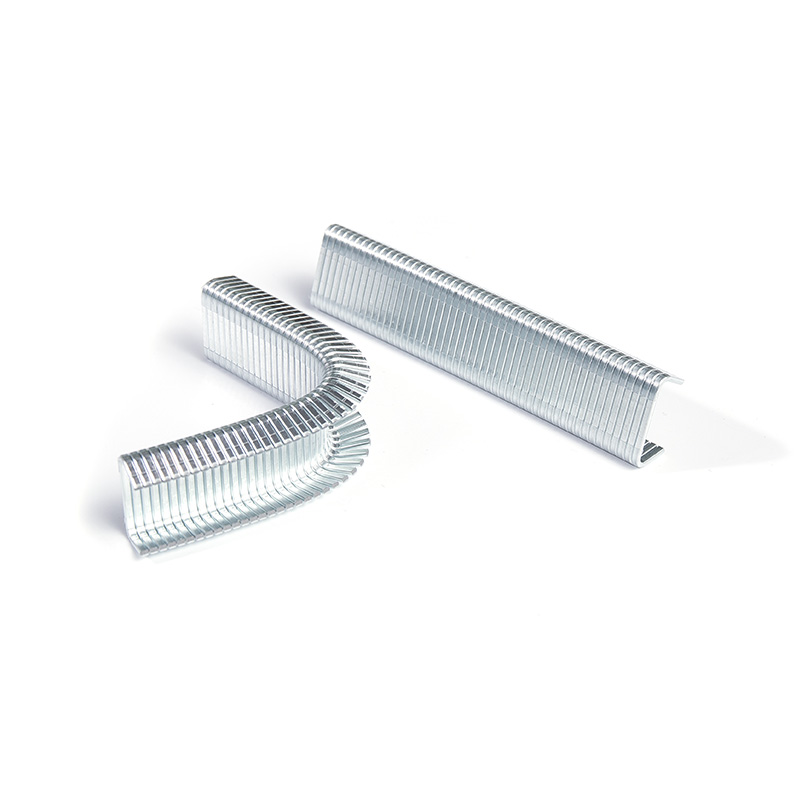

Fine wire staples are lightweight, narrow-gauge fasteners designed for precision applications where minimal material damage and discreet fastening are priorities. Unlike heavier fasteners, their thin wire construction reduces the risk of splitting delicate materials such as thin wood, fabric, or paper, making them ideal for specialized tasks across industries like crafting, upholstery, and light woodworking. These staples typically feature a smaller crown width and thinner gauge wire compared to standard staples, balancing holding power with gentleness on workpieces. Whether used for securing delicate fabrics to furniture frames or attaching thin trim to woodworking projects, fine wire staples offer a versatile solution for jobs that demand finesse without compromising on stability. Their design also allows for easier removal if adjustments are needed, a key benefit in projects where precision and reversibility matter.

- Material Composition: Most fine wire staples are made from high-quality steel, with some options featuring galvanized or stainless steel coatings to resist corrosion, especially for outdoor or humid environment applications.

- Gauge Variations: Common gauges for fine wire staples range from 20 to 22 gauge, with thinner gauges (22) suited for ultra-delicate materials and slightly thicker gauges (20) offering enhanced holding power for light woodworking.

- Crown Sizes: The crown (top width) of fine wire staples typically measures between 3/16 inch and 1/2 inch, with narrower crowns for discreet fastening and wider crowns for distributing pressure across larger surfaces.

- Leg Length Options: Leg lengths vary from 1/4 inch to 1 inch, allowing users to select the appropriate size based on the thickness of the materials being fastened.

Key Differences Between Fine Wire Staples and Standard Staples

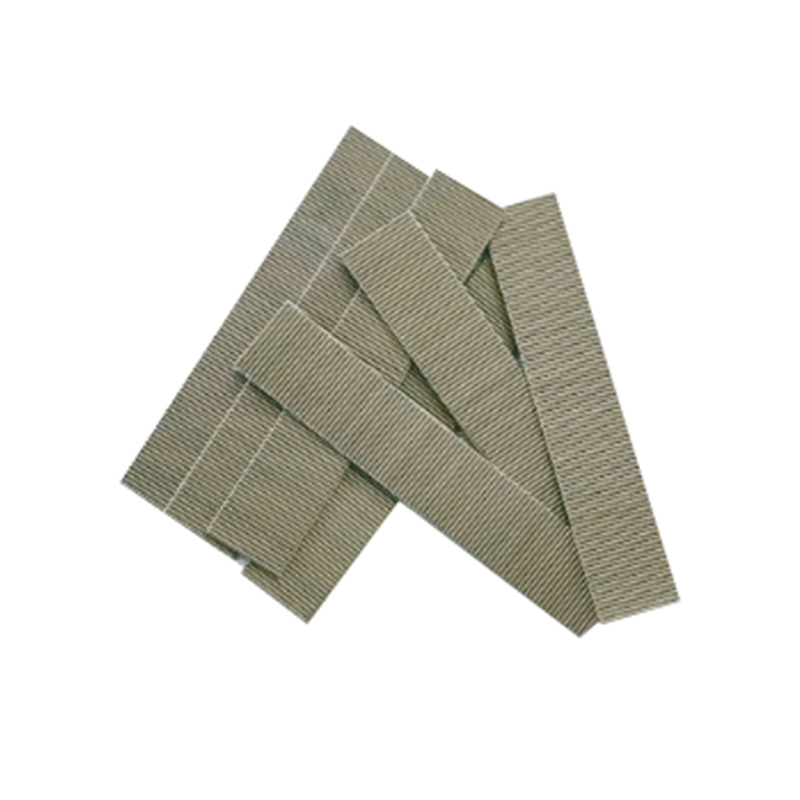

Understanding the differences between fine wire staples and standard staples is critical for choosing the right fastener for your application. Standard staples are designed for heavy-duty tasks, featuring thicker wire gauges (18 to 16 gauge) and wider crowns, which provide greater holding power for dense materials like thick cardboard, wood, or construction materials. In contrast, fine wire staples prioritize precision over brute strength, making them unsuitable for heavy loads but ideal for delicate work. The variance in design impacts not only their performance but also their compatibility with tools, as fine wire staples require specialized staple guns that can handle their narrow gauge without bending or jamming. Below is a detailed comparison of the two fastener types to highlight their core differences.

|

Feature |

Fine Wire Staples |

Standard Staples |

|

Wire Gauge |

20-22 gauge (thin, lightweight) |

16-18 gauge (thick, heavy-duty) |

|

Crown Width |

3/16 inch - 1/2 inch (narrow, discreet) |

1/2 inch - 3/4 inch (wider, more stable) |

|

Holding Power |

Moderate, suited for light to medium loads |

High, designed for heavy loads and dense materials |

|

Material Impact |

Minimal damage, ideal for delicate materials |

May cause splitting in thin or soft materials |

|

Common Applications |

Upholstery, crafting, light woodworking, paper binding |

Construction, packaging, heavy woodworking, industrial tasks |

Fine Wire Staples for Upholstery Projects

Upholstery is one of the most common applications for fine wire staples, as they excel at securing fabrics, foam, and padding to furniture frames without damaging delicate materials. When working with upholstery, the goal is to create a smooth, professional finish while ensuring the fabric stays in place long-term. Fine wire staples for upholstery projects are specifically designed to penetrate softwoods and composite frames without splitting the wood, while their narrow crowns prevent unsightly marks on visible fabric surfaces. Whether reupholstering a chair, refinishing a sofa, or creating custom cushions, these staples offer the precision needed to handle lightweight to medium-weight fabrics such as cotton, linen, velvet, and synthetic blends. Additionally, their corrosion-resistant coatings make them suitable for upholstery projects in humid environments, preventing rust from damaging the fabric or frame over time.

- Fabric Compatibility: Fine wire staples for upholstery projects work well with both natural and synthetic fabrics, including delicate materials like silk and heavyweight options like canvas, as their narrow crowns distribute pressure evenly to avoid tearing.

- Frame Material Considerations: These staples are optimal for softwood frames (e.g., pine, cedar) and composite materials, as their thin gauge minimizes the risk of splitting compared to standard staples, which may cause cracks in softer woods.

- Leg Length Selection: For upholstery, leg lengths between 1/4 inch and 3/8 inch are ideal for securing fabric to thin frames, while 1/2 inch legs work for attaching foam or padding to thicker frames.

- Application Techniques: When using fine wire staples for upholstery projects, space staples 1 to 2 inches apart along seams and edges to ensure even holding power, and avoid over-driving staples, which can damage fabric or frame.

|

Upholstery Task |

Ideal Fine Wire Staple Specs |

Advantage Over Standard Staples |

|

Securing top fabric to chair frame |

22 gauge, 3/16 inch crown, 3/8 inch leg |

No visible staple marks on fabric; no frame splitting |

|

Attaching foam padding to sofa base |

20 gauge, 1/2 inch crown, 1/2 inch leg |

Gentle on foam; prevents tearing while maintaining hold |

|

Reupholstering decorative cushions |

22 gauge, 3/16 inch crown, 1/4 inch leg |

Discreet fastening; easy removal for adjustments |

How to Choose the Right Gauge for Fine Wire Staples

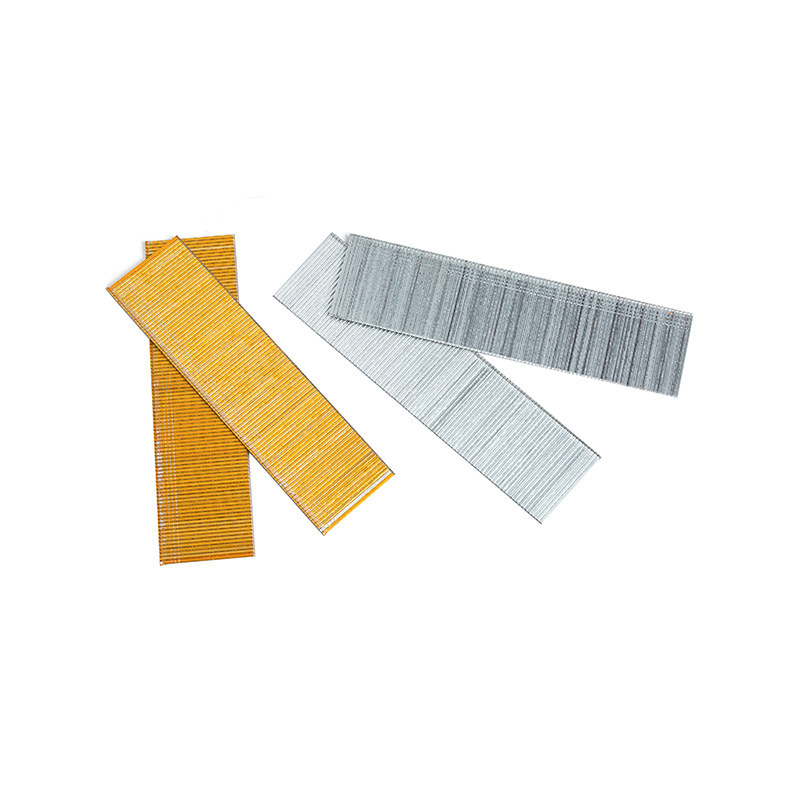

Selecting the correct gauge is essential for maximizing the performance of fine wire staples, as gauge directly impacts holding power, material compatibility, and application suitability. Gauge refers to the thickness of the staple wire, with lower gauge numbers indicating thicker wire. For fine wire staples, the most common gauges are 20, 21, and 22, each suited for specific tasks. Understanding how gauge correlates to application needs ensures that you choose staples that can handle the load without damaging the workpiece. Whether working on delicate crafting projects or light woodworking, selecting the right gauge prevents issues like staple bending, material splitting, or insufficient holding power. This section breaks down the key factors to consider when choosing a gauge and provides guidance on matching gauge to application.

- 22 Gauge Fine Wire Staples: The thinnest common gauge, ideal for ultra-delicate materials like thin paper, lightweight fabric, and small craft pieces. They offer minimal material damage but have the lowest holding power, making them unsuitable for heavy loads.

- 21 Gauge Fine Wire Staples: A versatile middle ground, suitable for a range of applications including upholstery, light woodworking, and packaging thin materials. They balance holding power and gentleness, working well with softwoods and medium-weight fabrics.

- 20 Gauge Fine Wire Staples: The thickest fine wire gauge, designed for light to medium woodworking, attaching trim, and securing thicker fabrics. They provide enhanced holding power compared to 21 and 22 gauge staples while still minimizing material damage.

- Gauge vs. Material Thickness: Thicker materials (e.g., 3/4 inch wood trim) require a lower gauge (20) for adequate penetration, while thinner materials (e.g., tissue paper crafts) need a higher gauge (22) to avoid tearing.

|

Gauge |

Wire Thickness (inches) |

Best Applications |

Limitations |

|

22 |

0.025 |

Crafts, thin paper, lightweight fabric, delicate upholstery |

Low holding power; not for wood or heavy materials |

|

21 |

0.032 |

Upholstery, light woodworking, packaging, trim work |

May bend in dense woods; not for heavy loads |

|

20 |

0.035 |

Thicker fabric, wood trim, light construction, foam attachment |

May damage ultra-delicate materials like silk |

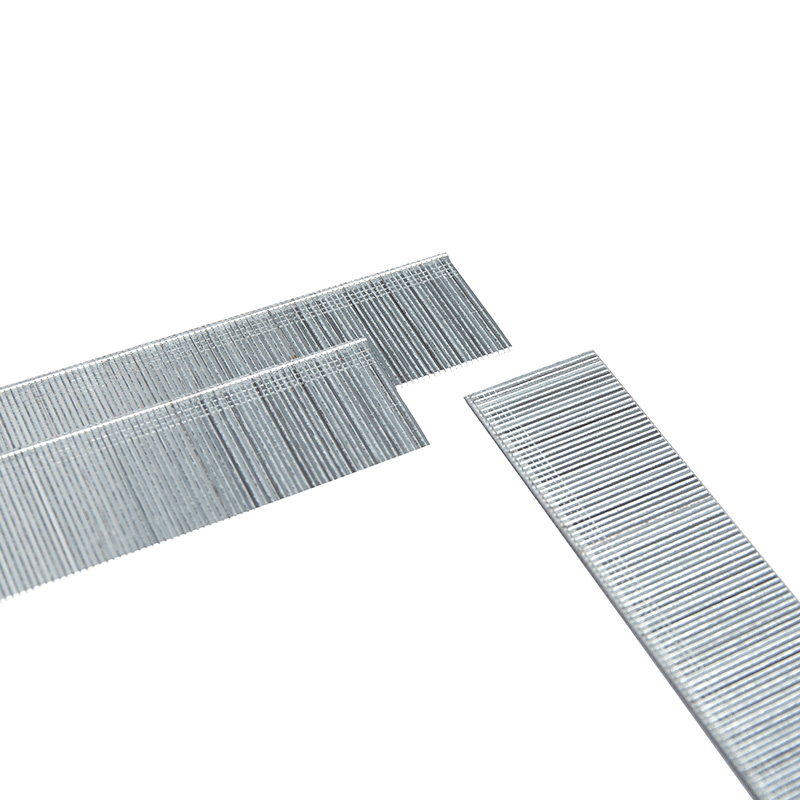

Fine Wire Staples vs. Brad Nails for Light Woodworking

In light woodworking, fine wire staples and brad nails are two popular fastener options, each with unique advantages depending on the project. Fine wire staples vs. brad nails for light woodworking is a common comparison, as both are designed for precision tasks without heavy-duty holding requirements. Brad nails are cylindrical, headless fasteners that offer a nearly invisible finish, while fine wire staples have a small crown that provides greater surface area for holding power. The choice between the two depends on factors like material type, desired finish, and holding strength needs. For projects where discreetness is paramount, brad nails may be preferred, but fine wire staples excel in applications where a stronger hold is needed without compromising on precision. Below is a detailed analysis of how these two fasteners compare in light woodworking scenarios.

- Holding Power: Fine wire staples offer superior holding power compared to brad nails due to their crown design, which distributes pressure across a larger surface area. This makes them ideal for attaching trim, molding, or thin wood pieces that need to stay securely in place.

- Finish Appearance: Brad nails leave a smaller hole (or no visible hole) since they are headless, making them better for projects where the fastener must be invisible. Fine wire staples have a small crown that may be visible, but their narrow design minimizes unsightly marks.

- Material Compatibility: Both work well with softwoods and composites, but fine wire staples are less likely to split thin wood pieces due to their distributed pressure, while brad nails may cause splitting if driven too close to the edge.

- Application Versatility: Fine wire staples are suitable for both wood-to-wood and wood-to-fabric applications (e.g., attaching fabric to a wooden frame), while brad nails are limited to wood-to-wood tasks.

|

Light Woodworking Task |

Fine Wire Staples |

Brad Nails |

|

Attaching decorative trim to a wooden box |

Better hold; crown distributes pressure to prevent trim splitting |

Invisible finish but may pull loose over time |

|

Building a lightweight wooden shelf |

Ideal for securing shelf brackets to the frame; strong hold |

May not provide enough hold for brackets; risk of shelf sagging |

|

Creating a wooden photo frame with a fabric back |

Perfect for securing fabric and wood; dual-material compatibility |

Cannot secure fabric; only suitable for wood-to-wood attachment |

Fine Wire Staples for Delicate Craft Projects

Craft enthusiasts rely on fine wire staples for a wide range of delicate projects, where precision and minimal material damage are non-negotiable. Fine wire staples for delicate craft projects are designed to handle thin, fragile materials like tissue paper, cardstock, ribbon, and small pieces of wood or foam without tearing, crushing, or splitting them. Unlike standard staples, which are too thick and bulky for crafts, these staples offer the perfect balance of strength and gentleness, allowing crafters to create intricate designs with confidence. Whether making scrapbooks, decorative wreaths, or handmade greeting cards, fine wire staples provide a secure fastening solution that preserves the integrity of delicate materials. Their small size also makes them easy to hide within the project, ensuring a clean, professional finish.

- Material Pairings: Fine wire staples for delicate craft projects work well with combinations of materials, such as attaching ribbon to cardstock, securing tissue paper to a foam wreath base, or fastening small wood pieces to a craft board.

- Size Selection: For crafts, 22 gauge staples with 3/16 inch crowns and 1/4 inch legs are optimal, as they are small enough to avoid overpowering delicate materials while still providing adequate hold.

- Tool Compatibility: Crafters should use a lightweight, handheld staple gun designed for fine wire staples, as heavy-duty guns may drive staples too deeply or bend them, damaging the project.

- Decorative Considerations: Many fine wire staples for delicate craft projects come in neutral colors (e.g., silver, black) to blend with craft materials, or can be painted to match the project for a seamless finish.

|

Craft Project Type |

Recommended Fine Wire Staple Specs |

Benefit for the Project |

|

Scrapbooking (attaching photos to pages) |

22 gauge, 3/16 inch crown, 1/4 inch leg |

Secure hold without damaging photos or paper; easy to hide |

|

Handmade wreaths (tissue paper and foam) |

22 gauge, 3/16 inch crown, 1/4 inch leg |

Gentle on foam and tissue; prevents tearing or crushing |

|

Miniature wooden crafts (dollhouse furniture) |

21 gauge, 3/16 inch crown, 3/8 inch leg |

Strong hold for small wood pieces; no splitting |

Fine Wire Staples for Paper and Document Binding

While standard staples are commonly used for paper binding, fine wire staples for paper and document binding offer a specialized solution for delicate or thin paper stacks, where standard staples may cause tearing or leave unsightly holes. These staples are designed with a narrow crown and thin gauge to penetrate paper without damaging the edges, making them ideal for binding thin booklets, newsletters, flyers, and delicate documents like vintage papers or archival materials. Unlike heavy-duty staplers, which use thick wire, fine wire staples provide a clean, professional bind that preserves the integrity of the paper, even with repeated handling. They are also easier to remove without tearing the paper, a key advantage for documents that may need to be edited or updated.

- Paper Stack Thickness: Fine wire staples for paper and document binding work best with stacks of 2 to 10 sheets of standard printer paper (20-24 lb). For thicker stacks, a slightly heavier gauge (21) may be needed, but they are not suitable for stacks exceeding 15 sheets.

- Archival Suitability: Galvanized or stainless steel fine wire staples are ideal for archival documents, as they resist rust and corrosion, preventing damage to paper over time compared to uncoated staples.

- Binding Position: These staples are best used for saddle stitching (binding along the fold) or edge binding, as their narrow crown fits neatly along folds without bulging, creating a flat finish.

- Tool Requirements: A compact, precision stapler designed for fine wire staples is necessary for paper binding, as it ensures consistent staple depth and prevents over-driving, which can tear paper.

|

Document Type |

Fine Wire Staple Specs |

Advantage Over Standard Staples |

|

Vintage paper booklets (archival binding) |

22 gauge, 3/16 inch crown, 1/4 inch leg (stainless steel) |

No rust damage; minimal paper tearing; preserves document integrity |

|

Thin newsletters (5-8 sheets) |

22 gauge, 3/16 inch crown, 1/4 inch leg |

Flat binding along folds; no bulging; easy to mail |

|

Delicate flyers (2-3 sheets of thin paper) |

22 gauge, 1/8 inch crown, 1/4 inch leg |

Ultra-narrow crown; no visible holes on the front of the flyer |

FAQ

Can fine wire staples be used outdoors?

Yes, fine wire staples can be used outdoors, but only if they are made from corrosion-resistant materials like galvanized or stainless steel. Standard steel fine wire staples will rust quickly when exposed to moisture, humidity, or harsh weather conditions, leading to fastener failure and potential damage to the workpiece. Galvanized fine wire staples are coated with a layer of zinc to resist rust, making them suitable for covered outdoor applications like attaching fabric to patio furniture or securing trim to a covered porch. Stainless steel fine wire staples offer superior corrosion resistance and are ideal for fully exposed outdoor projects, such as attaching wire mesh to garden frames or securing lightweight materials in coastal environments. It’s important to avoid using uncoated fine wire staples outdoors, as they will degrade rapidly and compromise the hold of the project.

What is the difference between fine wire staples and medium wire staples?

The primary difference between fine wire staples and medium wire staples lies in wire gauge, holding power, and application suitability. Fine wire staples typically range from 20 to 22 gauge, with thin wire and narrow crowns designed for delicate materials and precision tasks. They minimize material damage but offer moderate holding power, making them ideal for upholstery, crafts, and light woodworking. Medium wire staples, on the other hand, range from 18 to 19 gauge, with thicker wire and wider crowns that provide greater holding power. They are designed for heavier tasks like attaching thicker trim, securing wire mesh, or binding thicker material stacks, but they are more likely to split delicate or thin materials. Additionally, fine wire staples require specialized lightweight staple guns, while medium wire staples work with heavier-duty tools. The choice between the two depends on the material thickness and the required holding strength for the project.

How do I prevent fine wire staples from bending during application?

Preventing fine wire staples from bending during application requires proper tool selection, technique, and staple compatibility. First, use a staple gun specifically designed for fine wire staples—heavy-duty guns designed for medium or heavy wire staples will exert too much force, causing bending. Ensure the staple gun is loaded correctly, with fine wire staples aligned properly in the magazine to avoid jamming or misfeeding, which can lead to bending. When applying staples, hold the gun perpendicular to the workpiece to ensure even pressure and proper penetration. Avoid over-driving staples by adjusting the gun’s depth setting to match the material thickness—over-driving forces the staple into hard surfaces, causing it to bend. Additionally, choose the correct gauge for the material: using a 22 gauge staple on dense wood will likely cause bending, so opt for a 20 gauge staple for harder materials. Finally, inspect fine wire staples before use to ensure they are straight and free from defects, as damaged staples are more prone to bending.

Are fine wire staples reusable?

While fine wire staples can be removed from workpieces, they are not designed for reuse. The thin wire construction of fine wire staples makes them prone to bending, warping, or damaging the staple’s crown when removed, even with careful extraction using a staple remover. Reusing a bent or damaged fine wire staple will result in poor holding power, misfeeding in the staple gun, and potential damage to the workpiece. Additionally, removing fine wire staples can leave small bends or deformities in the wire that are not visible to the naked eye but will compromise the staple’s performance when reused. For optimal results, always use new fine wire staples for each project, as they are affordable and ensure consistent, reliable fastening. If you need to adjust a project, remove the old staples and replace them with new ones to maintain the integrity of the workpiece.

Can fine wire staples be used on hardwoods?

Fine wire staples are not ideal for use on hardwoods (e.g., oak, maple, walnut) due to their thin gauge and limited penetration power. Hardwoods are dense, and fine wire staples will likely bend, break, or fail to penetrate deeply enough to provide adequate holding power. Even 20 gauge fine wire staples, the thickest in the fine wire category, may struggle to penetrate hardwoods without bending, especially if the wood is dry or dense. For hardwoods, medium or heavy wire staples (16-18 gauge) are more suitable, as they have thicker wire and greater penetration power to secure materials effectively. However, fine wire staples can be used on softwoods (e.g., pine, cedar) and composite materials, which are less dense and allow for proper penetration without bending. If you must use fine wire staples near hardwoods, limit their use to attaching lightweight materials to the surface of hardwoods (not through the hardwood) and ensure the staple gun is set to the highest power setting.