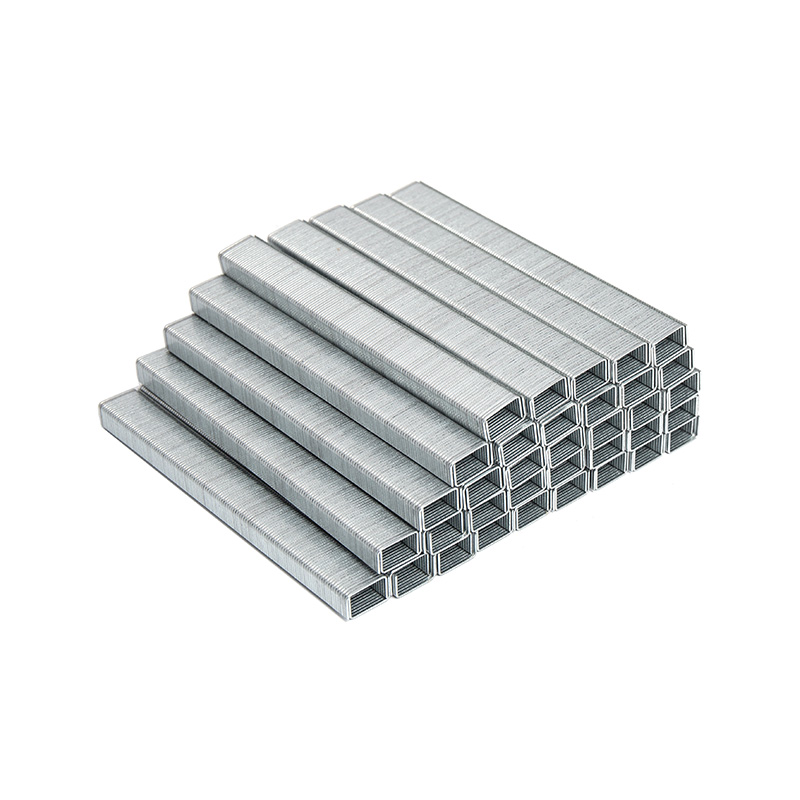

In the world of furniture manufacturing, upholstery, and carpentry, the integrity of a finished piece often hinges on components unseen by the end user. Among these, heavy duty furniture staples are fundamental. These robust fasteners provide the critical strength and durability required for high-stress applications, from the frame of a commercial sofa to the structure of a solid wood cabinet. Selecting the right staple is not merely a technical detail; it's a decision that impacts longevity, safety, and overall quality. This comprehensive guide delves into the specifics of heavy-duty staples, exploring their types, ideal applications, and key selection criteria to empower professionals and enthusiasts alike.

Understanding Heavy Duty Furniture Staples

Heavy duty furniture staples are defined by their gauge (thickness), crown width, leg length, and material composition. Designed to withstand significant shear and tensile forces, they are engineered for joining hardwoods, securing thick upholstery materials, and constructing frames that must bear weight over time. Unlike lighter staples, they minimize the risk of pull-out, frame distortion, or joint failure.

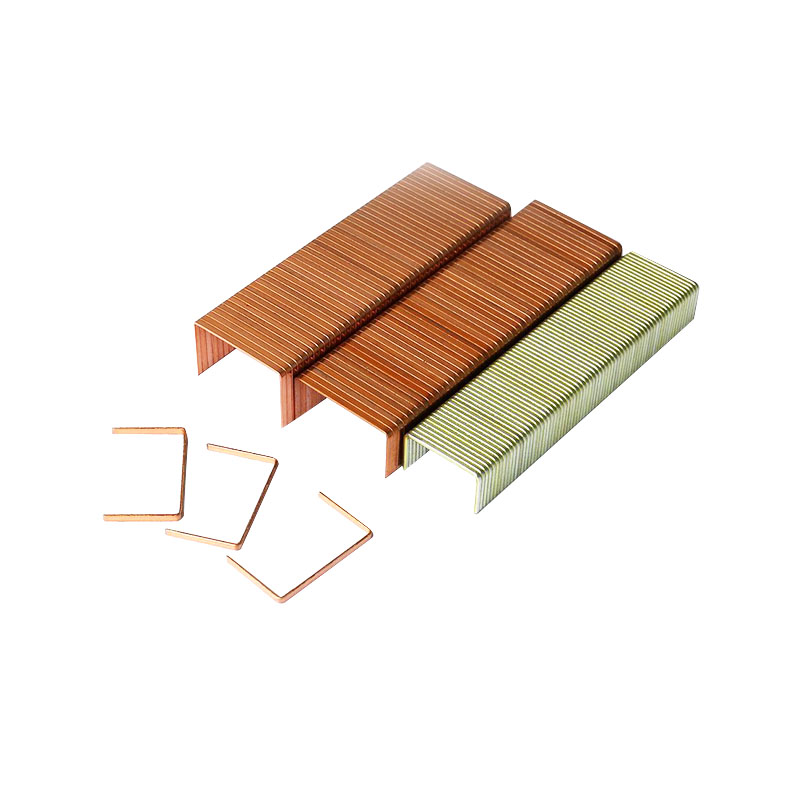

Core Materials and Coatings

Material Types

- Steel: The most common base material, offering a excellent balance of strength and cost-effectiveness.

- Stainless Steel: Provides superior corrosion resistance, essential for outdoor furniture or in high-moisture environments.

- Galvanized Steel: Features a zinc coating for enhanced rust protection, a good middle-ground for indoor furniture that may face occasional humidity.

Coating Benefits

- Prevents rust and oxidation, extending the life of the staple and protecting the surrounding material.

- Can reduce driving friction, allowing for smoother installation with pneumatic tools.

- Some specialized coatings improve grip and holding power.

Five Key Applications and Their Optimal Staple Choices

Choosing the correct staple requires matching its specifications to the task at hand. The following sections, based on high-value, low-competition search queries, provide targeted guidance for specific professional needs.

1. Best Staples for Upholstering Thick Fabrics

Upholstering with materials like leather, heavy-duty tweed, or multiple foam layers demands a staple that can penetrate deeply and hold firmly without tearing or "cupping" the fabric. A comparison of staple features for this application is essential.

For thick fabrics, a staple with a medium crown (e.g., 1/4" or 5/16") provides sufficient holding surface without being overly visible. A longer leg length (e.g., 1/2" or longer) is crucial to anchor into the hardwood frame beneath the padding. Using a staple that is too short or has too narrow a crown is a common cause of fabric loosening over time. The optimal choice balances holding power with a clean, secure finish.

| Feature | Ideal Choice for Thick Fabrics | Less Suitable Choice |

|---|---|---|

| Crown Width | Medium (5/16") | Narrow (1/4" or less) |

| Leg Length | Long (1/2" or more) | Short (3/8" or less) |

| Point Type | Chisel Point | Diamond Point |

| Coating | Galvanized | Plain (uncoated) |

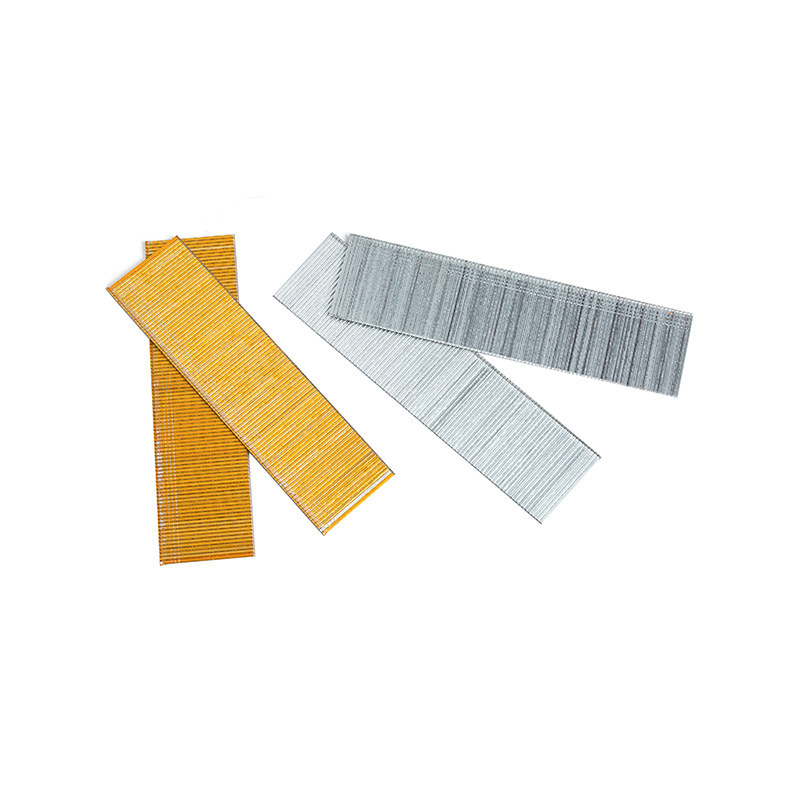

2. Heavy Duty Staples for Outdoor Furniture Frames

Outdoor furniture faces relentless enemies: moisture, temperature swings, and UV exposure. The frame's fasteners are its first line of defense. Heavy duty staples for outdoor furniture frames must prioritize corrosion resistance above all else. While gauge and length remain important for structural integrity, the material choice is paramount.

- Stainless Steel (Type 304 or 316): The gold standard. Highly resistant to rust and staining, ideal for marine or poolside environments.

- Heavily Galvanized Steel: A cost-effective alternative for general outdoor use where direct, constant weathering is less severe.

- Critical Consideration: Always ensure the staple material is compatible with the frame wood (e.g., avoid galvanic corrosion with certain treated woods).

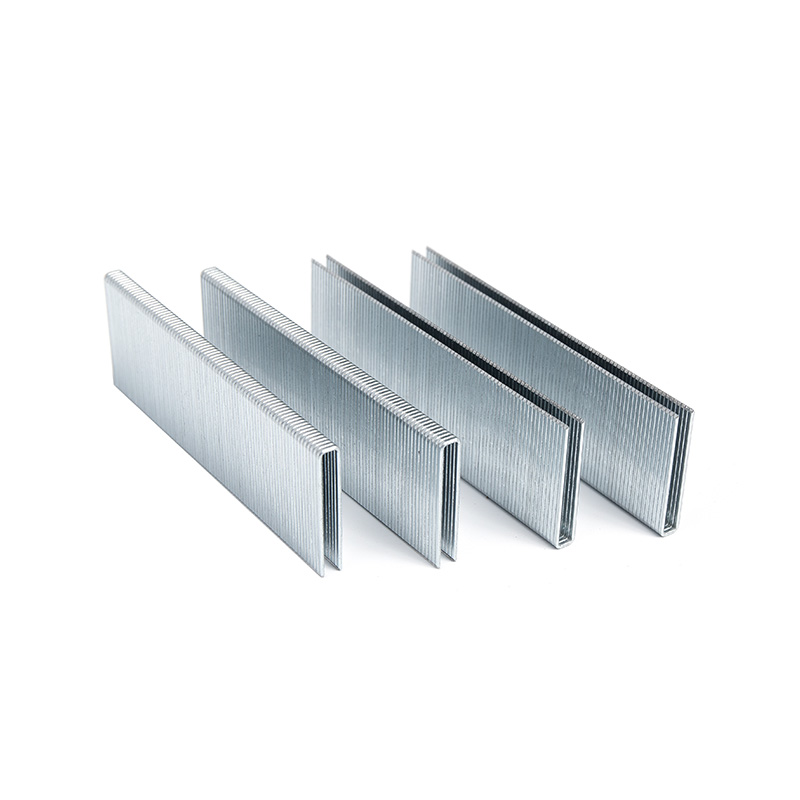

3. Strongest Staples for Hardwood Furniture Construction

Building furniture from hardwoods like oak, maple, or ash requires fasteners that can bite into dense grain without bending or shearing. The quest for the strongest staples for hardwood furniture construction focuses on gauge (thickness) and design.

- Thick Gauge (16 gauge or lower): Lower gauge numbers indicate thicker wire. 16, 15, or even 14 gauge staples provide the necessary rigidity.

- Heat-Treated/Tempered: These staples are hardened, increasing their shear strength and resistance to bending during installation into tough wood.

- Chisel Point: Cuts through wood fibers rather than wedging them apart, reducing splitting and allowing for easier penetration into hardwoods.

4. Industrial Strength Upholstery Staples Guide

Commercial settings—hotels, offices, airports—subject furniture to extreme continuous use. An industrial strength upholstery staples guide emphasizes durability, speed of application, and reliability. This involves a systems approach, considering the staple gun, staple size, and material.

| Application Context | Staple Specification Focus | Tool Recommendation |

|---|---|---|

| High-Volume Production Line | Consistency, magazine capacity, ease of loading | Heavy-duty pneumatic stapler |

| Commercial Chair Re-upholstery | High shear strength, anti-corrosion coating | Medium to heavy-duty electric or pneumatic stapler |

| Securing Multiple Fabric & Foam Layers | Long leg length, wide crown | Long-nose pneumatic stapler |

5. How to Choose Staples for Furniture Repair

Repair work presents unique challenges: matching existing fastener points, dealing with pre-drilled or compromised wood, and ensuring the repair is as strong as the original. Knowing how to choose staples for furniture repair is a skill that restores functionality and value.

- Assessment is Key: Identify the original staple gauge and length if possible. When in doubt, opt for a slightly thicker gauge or longer length for added strength in the repaired area.

- Dealing with Old Holes: For best holding power, drive new staples into fresh, solid wood adjacent to the old, weakened hole.

- Material Match: Choose a staple coating that matches or exceeds the corrosion resistance of the original to prevent new corrosion points.

- Minimizing Visibility: For visible repairs on the underside or interior, select a crown width that blends with existing fasteners.

Technical Specifications: Decoding Gauge, Crown, and Leg

Making an informed choice requires understanding the terminology.

- Wire Gauge: The diameter of the staple wire. Measured in American Wire Gauge (AWG). A lower number (e.g., 16) indicates a thicker, stronger staple than a higher number (e.g., 18).

- Crown Width: The measurement across the top of the staple. A wider crown distributes force over a larger area, reducing pull-through risk.

- Leg Length: The measurement from the crown to the point. Determines depth of penetration.

The Role of a Trusted Manufacturer: Zhejiang Tianying Hardware Co., Ltd

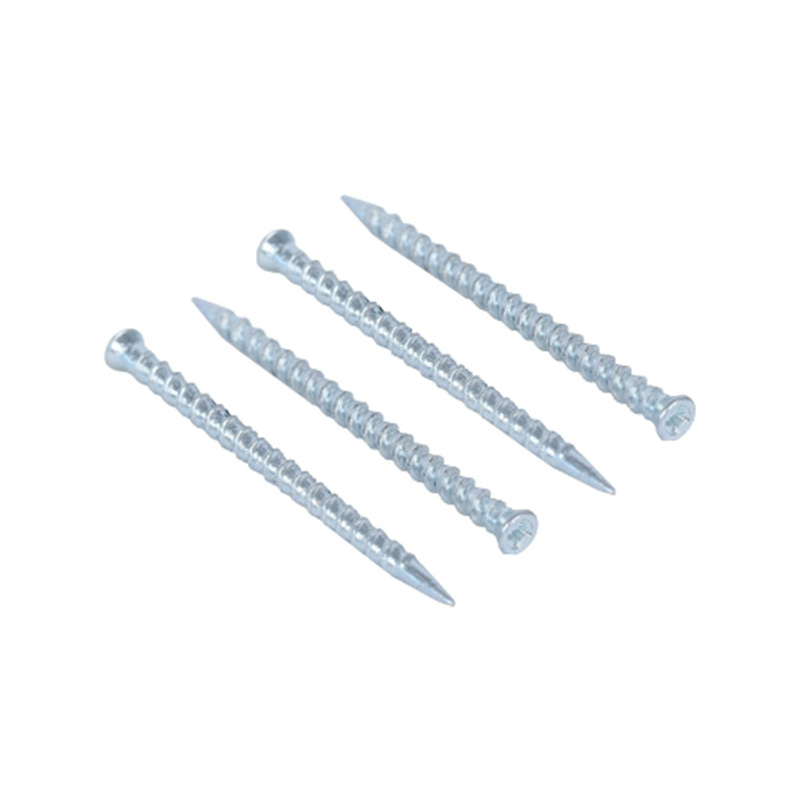

Producing reliable, consistent heavy duty furniture staples requires specialized expertise in metallurgy, precision engineering, and quality control. Zhejiang Tianying Hardware Co., Ltd, with its deep-rooted history originating from a factory with over two decades of experience, exemplifies this specialization. Located in the economically vibrant Yangtze River Delta, the company operates as an integrated entity managing research, design, production, and sales.

Their product range spans the critical needs discussed in this guide—from industrial and pneumatic nails to specialized staples for furniture, decoration, and fiberboard. By adhering to a strict policy of "quality of survival, quality of development, quality to benefit," Zhejiang Tianying Hardware ensures that its fasteners meet the high demands of furniture construction and repair. This dedication to serving customers with quality products makes them a pivotal partner for industries reliant on durable fastening solutions[1].

Frequently Asked Questions (FAQ)

What is the difference between 16-gauge and 18-gauge staples?

16-gauge staples are made from thicker wire than 18-gauge staples. This makes them stronger, more rigid, and better suited for heavy-duty applications like hardwood framing. 18-gauge staples are thinner and more flexible, ideal for lighter trim work or thin upholstery materials.

Can I use regular staples for outdoor furniture?

It is strongly discouraged. Regular, uncoated steel staples will rust quickly when exposed to moisture, leading to joint failure, stains on the furniture, and a significantly shortened lifespan. Always use stainless steel or heavily galvanized staples designed for outdoor use.

How do I prevent wood from splitting when stapling?

Use staples with a chisel point, which slices through wood fibers. Ensure the leg length is appropriate—too long for thin wood can cause blowouts. Stapling along the grain, rather than across it, and avoiding the very edge of a board also helps. For very hard or brittle woods, pilot holes may be necessary even for staples.

What does "crown width" mean, and why does it matter?

Crown width is the measurement across the top of the staple. A wider crown (e.g., 1/2") provides a larger bearing surface, distributing holding force over a greater area. This is crucial for securing fabrics, webbing, or thin panels to prevent tear-through. A narrower crown is less visible and used where material is thick enough to hold on its own.

How do I choose the right leg length?

The staple leg should be long enough to penetrate through the material being fastened and embed deeply into the underlying substrate (usually wood). A good rule is that the staple should penetrate the substrate by at least 3/8 inch. For example, to secure a 1/4" thick fabric and foam layer, you would need a staple with a leg length of at least 5/8".

Selecting the correct heavy duty furniture staples is a nuanced but critical aspect of woodworking and upholstery. By understanding the specific demands of your project—whether it's upholstering thick fabrics, building outdoor furniture frames, executing hardwood furniture construction, following an industrial strength upholstery staples guide, or mastering how to choose staples for furniture repair—you ensure durability, safety, and professional results. Partnering with experienced manufacturers who prioritize quality, such as Zhejiang Tianying Hardware Co., Ltd, provides access to the reliable fastening solutions that form the unseen backbone of exceptional furniture.

References

[1] Company Profile: Zhejiang Tianying Hardware Co., Ltd. (n.d.). Company history and quality policy. Internal company documentation.

[2] American Wood Council. (2018). National Design Specification® (NDS) for Wood Construction. Provides engineering data on fastener shear and tensile values in wood, relevant to staple holding power principles.

[3] International Staple, Nail and Tool Association (ISANTA). (2020). Fastener Standards & Nomenclature. Defines industry standards for wire gauge, crown, leg length, and point types for staples and nails.