Understanding Thin Line Staples and Their Unique Applications

Thin line staples represent a specialized category of fasteners designed for precision and minimal visibility. Unlike their bulkier counterparts, these staples are characterized by their narrow crown width and fine gauge, allowing them to perform tasks where a discreet and clean finish is paramount. They are the unsung heroes in various fields, from delicate crafting to critical document binding, offering a secure hold without the visual bulk or potential damage of standard staples. Their development was driven by the need for a fastener that could handle fragile materials and tight spaces, a need that traditional staples simply could not meet effectively. This section delves into the fundamental characteristics that define thin line staples and sets the stage for understanding their diverse utility.

What Exactly Defines a Thin Line Staple?

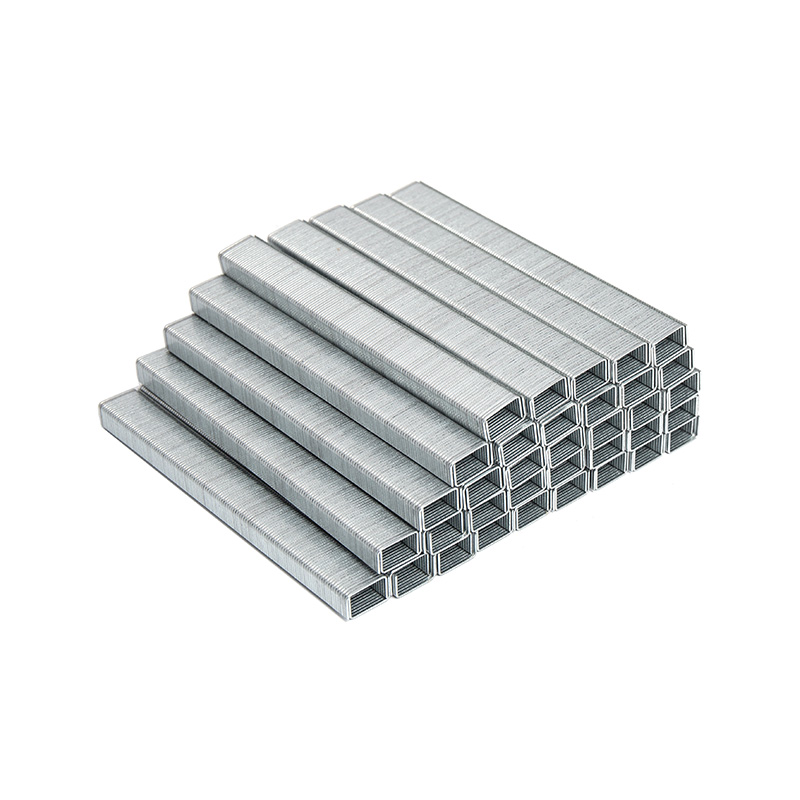

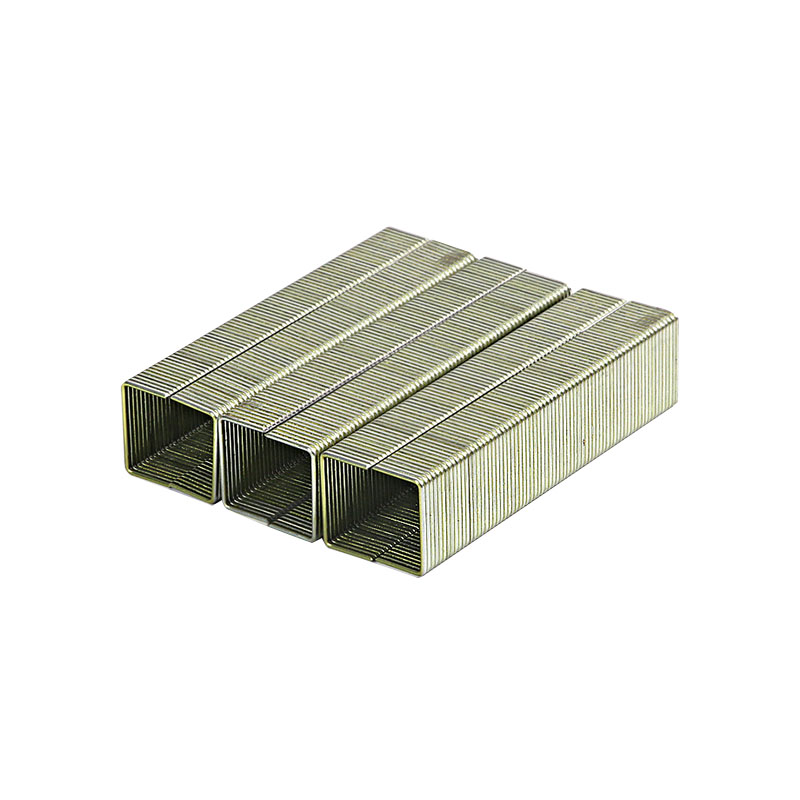

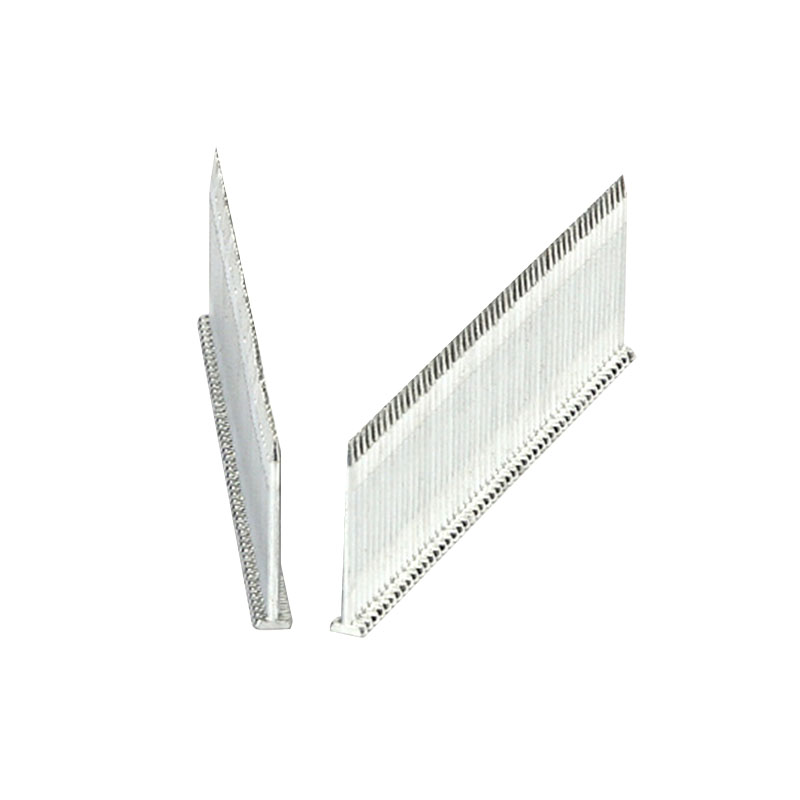

The primary distinguishing feature of a thin line staple is its crown width, which is significantly narrower than that of a standard staple. This reduced profile is the key to its specialized functionality. Typically, these staples are manufactured from a finer gauge wire, making them less obtrusive and reducing the risk of splitting or damaging delicate materials like paper, fabric, or thin wood veneers. The legs are often precisely formed to ensure consistent penetration and secure clinching. This precision engineering makes them ideal for applications where the staple must be both strong and nearly invisible. The term "thin line" itself often refers to a specific size category within the broader staple universe, but it has become a catch-all for any staple designed with a narrow crown for discreet fastening.

The Evolution of Precision Fastening

The journey of the thin line staple is intertwined with advancements in office technology and craftsmanship. Initially, staplers were bulky devices meant for heavy-duty joining, but as paperwork became more refined and the demand for elegant presentation grew, the market demanded a subtler solution. The introduction of the first staplers designed for these finer staples revolutionized document finishing, allowing for booklets and reports that looked professionally bound. Simultaneously, in the crafting and woodworking worlds, artisans sought a way to secure delicate materials without the unsightly marks left by larger fasteners. This confluence of needs from different sectors spurred innovation, leading to the development of the high-precision staplers and the variety of thin line staples for delicate paper we have today.

Key Advantages of Opting for Thin Line Staples

Choosing thin line staples over standard options offers a multitude of benefits that extend far beyond mere aesthetics. These advantages make them an indispensable tool for professionals and hobbyists alike who require a combination of strength, discretion, and material compatibility. The decision to use a specific type of staple can significantly impact the quality and durability of the final product, whether it's a cherished photo album, an important business proposal, or a delicate piece of upholstery. By understanding these core benefits, users can make informed decisions that enhance their work and avoid the common pitfalls associated with using the wrong fastener for the job.

Enhanced Precision and Reduced Material Damage

The most immediate benefit of using thin line staples is the drastic reduction in material stress and visible damage. Their fine gauge and narrow crown exert less pressure upon entry, which is crucial for preventing tears in delicate papers or splits in fragile wood. This precision ensures that the focus remains on the content being fastened, not the fastener itself. For instance, when mounting important documents or photographs, a standard staple can create noticeable ripples or even puncture the material, whereas a thin line staple provides a secure hold with minimal impact. This characteristic is why they are the preferred choice for archivists, scrapbookers, and anyone working with valuable or delicate items where preservation is key.

Improved Aesthetic and Professional Finish

In any application where appearance matters, thin line staples provide a superior finish. Their low-profile design sits flush against the material and is far less obtrusive, contributing to a cleaner, more professional look. This is particularly important in formal documentation, presentation materials, and published booklets. The staple line is neat and tidy, avoiding the bulky, crumpled appearance that can result from larger staples. This aesthetic advantage also extends to crafts and light woodworking projects, where the goal is often to create a seamless join that doesn't detract from the overall beauty of the piece. The ability to fasten securely while maintaining elegance is a powerful combination that elevates the quality of any project.

Selecting the Right Thin Line Staples for Your Needs

Not all thin line staples are created equal, and selecting the appropriate variant is critical for achieving optimal results. The market offers a range of options differentiated by size, wire gauge, coating, and leg shape. Using the wrong type can lead to jamming in your stapler, insufficient holding power, or even damage to your materials. Therefore, a thorough understanding of the specifications and how they align with your intended application is essential. This section will break down the key selection criteria, providing a clear roadmap for choosing the perfect staple for everything from binding important reports to securing delicate fabrics, ensuring that your best thin line staples for booklets are always on hand.

Deciphering Staple Specifications: Size and Gauge

The two most critical specifications to understand are crown width and leg length. Crown width determines how visible the staple will be on the surface of the material, while leg length determines how deep it can penetrate and what thickness it can fasten. These are often denoted by a standard numbering system. Furthermore, the wire gauge indicates the thickness of the wire used; a higher gauge number means a thinner, finer wire. For example, a fine-gauge staple is excellent for thin line staples for documents as it minimizes hole size, whereas a slightly thicker gauge might be chosen for a more rigid material that requires a stronger hold. The following table illustrates common thin line staple sizes and their typical uses:

| Staple Size Designation | Crown Width (approx.) | Leg Length Range | Ideal Application |

|---|---|---|---|

| Fine (e.g., 25/6) | 11.5 mm | 4-6 mm | Sheets of paper, light cardstock |

| Medium (e.g., 25/8) | 11.5 mm | 8-10 mm | Thick reports, thin cardboard |

| Heavy-duty Fine (e.g., 26/6) | 11.5 mm | 4-6 mm | Fabric, insulation, crafts |

Material and Coating Considerations

The base material and any protective coatings on a staple play a vital role in its performance and longevity. Most staples are made from steel for strength, but this steel can be prone to rust over time, especially in varying humidity. For documents or items intended for long-term storage or display, opting for stainless steel staples is advisable to prevent unsightly rust stains. Galvanized staples, coated with a layer of zinc, offer good rust resistance for general use. Additionally, some staples come with a painted finish, which can help them blend in with the material they are fastening, further enhancing their discreet nature. For those working on thin line staple guns for upholstery, choosing a staple with the correct coating can mean the difference between a lasting repair and one that fails due to corrosion.

Practical Applications Across Different Domains

The versatility of thin line staples allows them to be used in a surprising number of scenarios. Their value is recognized in environments as diverse as corporate offices, artist studios, and construction sites. By providing a secure yet subtle fastening method, they solve problems that other adhesives or fasteners cannot. This section explores the practical, everyday uses of these staples, demonstrating why they are a staple (pun intended) in many toolkits. From ensuring a professional bind on a business plan to securing the fabric on a vintage chair, the applications are nearly endless, limited only by the user's imagination and understanding of the product's capabilities.

Office and Documentation Excellence

In the office setting, presentation is everything. Thin line staples are the go-to choice for creating reports, proposals, and booklets that demand a polished look. They are capable of binding a higher number of sheets neatly compared to standard staples, which can struggle and leave a messy finish with thicker stacks. The clean penetration and secure clinch prevent pages from becoming loose over time, ensuring that important documents remain intact. This reliability makes them indispensable for legal offices, administrative departments, and anyone who regularly produces multi-page materials. The use of a thin line stapler for thick stacks equipped with the right staples ensures that even the most substantial documents are bound with a clean, professional edge that makes a positive impression.

Crafting, DIY, and Specialized Uses

Beyond the office, the world of crafting and DIY presents a fertile ground for thin line staples. Scrapbookers use them to attach photos and embellishments without the bulk of glue dots or tape. Model builders find them useful for securing small parts or wiring. In light upholstery work, a manual staple gun loaded with fine-gauge staples is perfect for reattaching fabric to furniture frames without splitting the wood or leaving large holes. Electricians and installers use them to secure low-voltage wiring and insulation materials neatly. The key in all these applications is the combination of holding power and minimal invasiveness, allowing for creative and functional fixes that are both effective and aesthetically pleasing. For these specialized tasks, finding a thin line staple gun for upholstery that is ergonomic and reliable is as important as the staples themselves.

Maximizing Performance and Avoiding Common Pitfalls

To get the most out of your thin line staples, proper usage and maintenance are paramount. A high-quality staple can still perform poorly if used incorrectly or in a mismatched stapler. Common issues such as jamming, misfiring, and failing to clinch properly can often be traced back to a few simple causes. Understanding how to avoid these problems will save time, reduce frustration, and ensure a perfect result every time. This final section provides essential tips and best practices for handling, loading, and using both manual staplers and staple guns, turning you into an expert in precision fastening.

Ensuring Smooth Operation and Preventing Jams

Staple jams are the most common frustration users face. They typically occur due to a few preventable reasons. Firstly, always use staples that are specifically recommended for your stapler model. Mixing sizes or types, even if they look similar, is a primary cause of jams. Secondly, avoid overloading the staple chamber; press the follower spring down gently and load the strip of staples until it is held securely without force. Forwards pressure from the spring should do the rest. Thirdly, keep your stapler clean and free from dust and debris, which can interfere with the mechanism. If a jam does occur, refer to the manufacturer's instructions for clearing it, usually involving carefully removing the stuck staple with needle-nose pliers rather than using excessive force which can damage the stapler.

Achieving the Perfect Fasten Every Time

The goal is a securely fastened staple that is neatly clinched on the other side. To achieve this consistently, ensure you are using the correct leg length for your material thickness. If the legs are too long, they may not clinch properly or could protrude dangerously; if they are too short, the fasten will be weak. Apply firm, even pressure when activating a manual stapler, and hold the tool perpendicular to the material surface to ensure straight entry. When using a staple gun, ensure it is pressed firmly against the work surface before firing to guarantee proper depth and clinching. By following these simple guidelines, you can leverage the full potential of thin line staples to create strong, discreet, and professional fastens in all your projects.