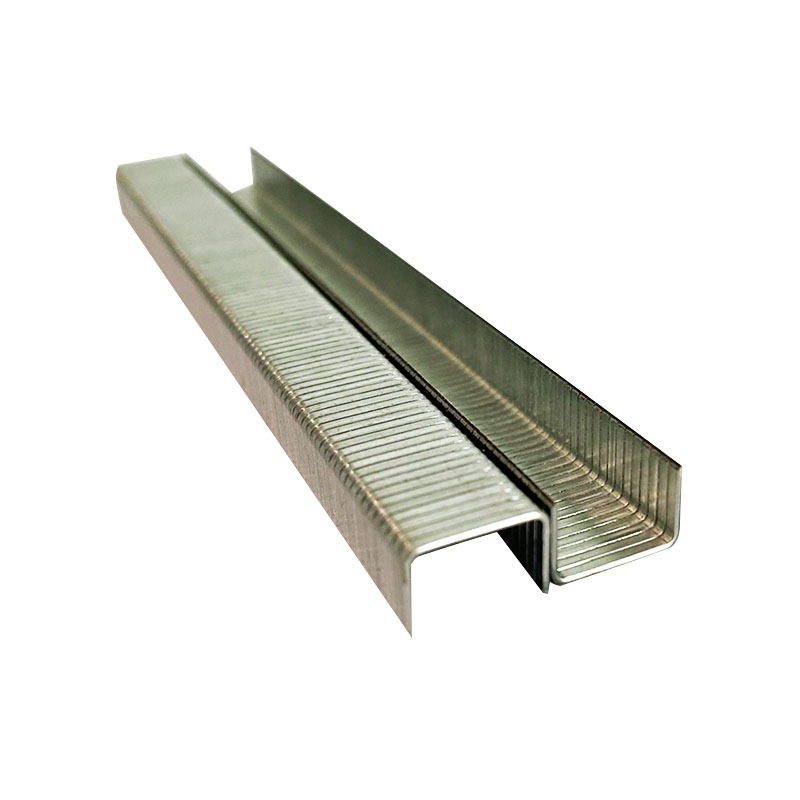

What Fine Wire Staples Are and Where They Shine

Fine wire staples are slender, light-duty to medium-duty fasteners designed to attach soft or thin materials without crushing, cracking, or leaving oversized holes. Compared with heavier staples, they have thinner wire diameters and typically a smaller crown, which spreads clamping pressure just enough to hold fabrics, veneers, foils, and light woods without the risk of tearing or imprinting. The smaller wire diameter also means reduced driving energy and a cleaner exit profile, which is particularly valuable for upholstery, picture framing backings, acoustic panels, lamp shades, bookbinding, and lightweight trim. When you are working on furniture or décor where the fastener must be discreet, fine wire staples provide a tidy, nearly invisible solution once covered by fabric, braid, or edge tape. For many projects, especially those involving textiles, fine wire staples for upholstery represent the sweet spot between secure hold and minimal surface disturbance.

Core benefits in delicate materials

The defining strength of fine wire staples is in delicate substrates—fabrics, thin plywood, MDF skins, cork, felt, and leather—where a heavy, thick fastener would telegraph through or split the material. Because the wire is thinner and the crown is narrower, penetration is smoother and the driver blade can seat the staple without crushing fibers. This reduced impact is crucial for maintaining the “hand” of a fabric, the crisp line of a mitered trim, or the flatness of a veneer. Additionally, the fine profile allows you to place fasteners densely along edges and corners, distributing load while keeping each individual footprint tiny and easy to conceal.

Typical projects where fine wire staples excel

- Reupholstering chair seats, backs, and headboards where staples will be hidden beneath dust covers or welting.

- Attaching canvas, burlap, batting, or webbing to wood frames without shredding fibers.

- Securing thin veneers and edge banding prior to clamping or while adhesives cure.

- Fixing fabric liners in drawers, jewelry boxes, and decorative cases where minimal imprint matters.

- Mounting backer boards, photo backings, and dust covers in frames and shadow boxes.

- Craft and DIY projects such as acoustic panels, screen frames, lamp shades, and lightweight trim.

When to consider alternatives

If your substrate is thick hardwood, structural plywood, or framing lumber, heavier narrow-crown staples or brads may provide better withdrawal resistance. For outdoor structural fastening, look for heavier gauges and weather-appropriate coatings or move to screws. As a rule, fine wire staples trade brute holding power for finesse; that trade is ideal in decorative, soft, or thin materials where the look matters as much as the hold.

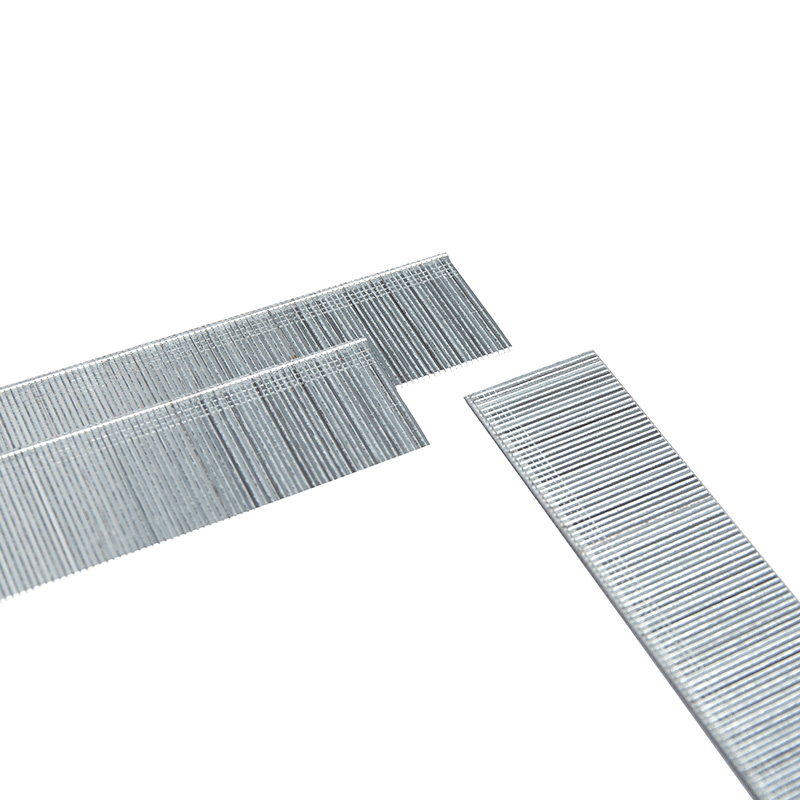

Sizing Decisions: Gauge, Crown, and Leg Length

Choosing size correctly avoids most failures: blow-through, puckering, visible crown lines, and premature pull-out. Size has three components—wire gauge (thickness), crown width (the top bridge that straddles the surface), and leg length (penetration depth). Among common options, 22 gauge fine wire staples are a favorite for upholstery because they balance a slim footprint with adequate holding strength for fabrics and light woods. A practical way to plan your selection is to consult a fine wire staples size chart and then test on scrap material that matches your project. The chart helps you translate substrate thickness and hardness into a sensible leg length, plus a crown that will distribute load without telegraphing. In softwoods or MDF skins, a slightly longer leg often gives a cleaner seat; in hardwood or plywood, a shorter leg can reduce the risk of tip blow-out along edges.

How to pick gauge, crown, and leg length step-by-step

- Match wire gauge to material sensitivity: the thinner the surface, the finer the wire. For most fabrics and liners, 20–22 gauge works well.

- Select crown width to distribute load: narrow crowns hide better; slightly wider crowns reduce risk of tearing on coarse fabrics.

- Choose leg length so 1/3 to 1/2 of the leg is embedded in sound wood beyond the attached layer; avoid tips poking through.

- Drive a test strip and adjust depth so crowns sit flush, not crushed below the surface.

Describing key differences before the table

Finer gauges make smaller holes and lower impact but hold a bit less; wider crowns spread pressure but show more under thin fabric; longer legs increase withdrawal resistance but raise the risk of blow-through on thin frames. The “best” combination depends on a gentle balance between invisibility and sufficient hold for handling and long-term use.

Reference table — fine wire staples size chart (typical, project-planning ranges)

| Use Case | Recommended Gauge | Common Crown | Typical Leg Length | Notes |

|---|---|---|---|---|

| Light fabric to softwood frame | 21–22 gauge fine wire staples | ~3/8" (9–10 mm) | 1/4"–3/8" (6–10 mm) | Fine footprint; test for pucker on thin fabrics. |

| Upholstery fabric + batting to plywood | 20–22 gauge | 3/8"–1/2" (9–12 mm) | 3/8"–1/2" (10–12 mm) | Wider crown reduces tear on coarse weave. |

| Veneer or edge banding tack-in | 20–21 gauge | 3/8" (9–10 mm) | 1/4"–3/8" (6–10 mm) | Keep legs short to avoid telegraphing through veneer. |

| Drawer liners / backer board | 20–21 gauge | 3/8"–1/2" | 3/8"–5/8" (10–16 mm) | Use longer legs only with thicker backers. |

| Leather or faux leather to hardwood | 20–21 gauge | 3/8" | 1/4"–3/8" | Pre-pierce edge on very stiff hides; test depth carefully. |

Materials and Coatings: Choosing for Durability and Appearance

The material and finish of a staple influence corrosion resistance, color stability, and long-term holding power. When humidity, spills, or outdoor exposure are in play, corrosion can stain fabrics and weaken joints. That is where stainless steel fine wire staples are invaluable: stainless resists rust and pitting, making it the go-to choice for kitchens, bathrooms, patios, marine cushions, and any application where moisture or salt is likely. In drier indoor spaces, coated carbon steel fasteners are often sufficient and cost-effective, especially when the staple will be buried under fabric or trim and not exposed to liquids. If your project uses tannin-rich woods (like certain hardwoods), look for finishes that reduce chemical staining. The choice is not purely about rust; it is also about matching color and sheen to avoid a faint “shadow” under thin, light-colored fabrics.

Describing the trade-offs before the table

Stainless costs more but provides the longest life and the least risk of staining; galvanized or zinc-coated carbon steel offers a good balance of economy and protection for indoor use; copper-coated carbon steel blends in visually under warm-toned fabrics but is not a substitute for true corrosion resistance; aluminum staples resist corrosion but are softer, making them better for ultra-light materials than dense hardwoods. Think of this as a spectrum from maximum durability (stainless) to maximum economy (plain or lightly coated carbon steel), and place your project accordingly.

Comparison table — materials and coatings

| Material / Finish | Corrosion Resistance | Relative Cost | Best Use Cases | Notes |

|---|---|---|---|---|

| stainless steel fine wire staples | Excellent (moisture & salt) | Higher | Outdoor cushions, kitchens, baths, marine trim | Minimizes rust stains on fabric and wood. |

| Galvanized / Zinc-coated carbon steel | Good (indoor humidity) | Moderate | General interior upholstery and trim | Solid indoor choice when liquid exposure is rare. |

| Copper-coated carbon steel | Fair | Moderate | Warm-tone fabrics, decorative backings | Color blends but not for high-moisture environments. |

| Aluminum | Good (non-rusting) | Moderate | Very light materials, non-structural crafts | Softer; may bend in dense hardwoods. |

Use-Case Playbooks and Comparisons

Translating specs into action is easier with playbooks. In upholstery, seat bottoms often combine several layers: fabric, batting, webbing, and dust cover. The trick is controlling drive depth so the crown sits flush but does not cut threads. For coarse weaves, a slightly wider crown helps distribute pressure and reduce tear-out; for delicate fabric, a narrow crown and shorter leg protect the surface. In trim work, use shorter legs near miters to avoid blow-out along edges, and angle the tool slightly so legs diverge inside the substrate, increasing withdrawal resistance. When you weigh fine wire staples vs narrow crown staples, think in terms of visibility and holding force: fine wire wins on minimal footprint and fabric safety; narrow crown wins on raw holding strength in thicker, denser materials.

Upholstery workflow (works especially well with fine wire staples for upholstery)

- Stretch fabric evenly; tack a center starter staple on each side.

- Work outwards in small increments, alternating sides to keep tension balanced.

- Use 20–22 gauge with 3/8" crown and a leg length matched to frame thickness.

- Flip, check for puckers, and adjust depth before committing to full runs.

Comparison in words before the table

Fine wire staples are less likely to leave visible tracks under thin fabrics, while narrow-crown staples provide deeper bite in subfloors, cabinet carcasses, and thicker trim. If the fastener will be concealed and the substrate is robust, narrow-crown may be superior; if the surface is visible or delicate, fine wire is safer and tidier.

Table — fine wire staples vs narrow crown

| Criterion | Fine Wire Staples | Narrow-Crown Staples |

|---|---|---|

| Surface visibility under thin fabrics | Minimal; ideal for delicate coverings | More visible; crown can telegraph |

| Holding power in thick, dense substrates | Moderate | High |

| Risk of tearing fabric | Low with proper crown and depth | Higher on delicate weaves |

| Best use cases | Upholstery, backings, veneers, crafts | Cabinet frames, sub-assemblies, heavier trim |

| Typical gauges | 20–22 gauge | 16–18 gauge |

Safety, Care, Troubleshooting, and Cost-Saving Tips

Safety and upkeep ensure cleaner results and a longer-lived tool. Always wear eye protection; even fine wire staples can ricochet from dense knots or hidden metal. Keep hands clear of the muzzle, and never reach behind the workpiece while firing. Use the correct fastener series for your stapler to prevent jams and misfires. A few drops of tool oil in pneumatic models reduces wear and helps maintain consistent drive energy—critical for even crown seating. If you experience frequent jams, check that staples are not bent in the strip, the magazine is clean, and your air pressure is within the recommended range. Depth settings matter: too deep and crowns cut fabric; too shallow and staples sit proud and snag textiles. For storage, keep fasteners dry and sealed; moisture can degrade coatings and cause staining during long-term use. To stretch your budget, buy leg lengths you will actually use instead of “one-size-fits-all”; test with the fine wire staples size chart logic first, and keep a small variety pack for edge cases rather than large stocks of seldom-used sizes.

Quick troubleshooting list

- Staples sitting proud: Increase depth slightly or check for insufficient air pressure.

- Fabric tearing: Move to a wider crown or reduce depth; consider a finer gauge.

- Frequent jams: Verify staple series match, clean the magazine, replace worn driver blades.

- Blow-through near edges: Shorten leg length; angle the tool so legs diverge.

- Rust stains over time: Switch to stainless steel fine wire staples for damp locations.

Economy and sustainability tips

- Plan cuts and staple runs to minimize re-stapling; every re-drive weakens fibers.

- Reserve stainless for environments that need it; use coated carbon steel indoors to manage cost.

- Keep offcuts for test drives; your material scraps are the best calibration bench.

Key Takeaways and Quick Selection Checklist

The fastest way to pick the right staple is to follow an ordered checklist that accounts for material delicacy, exposure, and appearance. Start with the substrate and covering, not the tool: if the material is thin, visible, or easily damaged, fine wire is the safer class of fastener; if the substrate is thick and the fastener will be buried, you may step up in gauge or crown. Tie the environment to material choice: dry indoor pieces tolerate coated carbon steel, while kitchens, baths, patios, and marine cushions merit stainless steel fine wire staples. Translate the project into specific numbers using the logic of a fine wire staples size chart: for upholstery with softwood frames, 22 gauge fine wire staples, ~3/8" crown, and 1/4"–3/8" legs are a dependable starting point; for veneer or edge banding, keep legs short to prevent telegraphing. Finally, sanity-check your choice against the alternative class in fine wire staples vs narrow crown terms: when minimal surface imprint and fabric safety outrank maximum hold, stay with fine wire; when you need extra bite in thicker assemblies, narrow crown may be worth the visibility trade-off. If you remember nothing else, remember this: match gauge to delicacy, crown to tear-resistance, leg to thickness, and material to moisture—and always test on scrap before committing to production runs. This simple loop saves time, protects your project, and elevates the finish in ways that are obvious even to a casual eye.

One-minute checklist

- Material delicacy: fabric/veneer → fine wire; thick hardwood → consider heavier class.

- Environment: damp or outdoor → use stainless steel fine wire staples.

- Size: start with 22 gauge fine wire staples and adjust crown/leg from test drives.

- Compare: revisit fine wire staples vs narrow crown before final selection.

- Document: record your winning setup to build your own fine wire staples size chart for future jobs.