Understanding the Fundamentals of Heavy-Duty Staples

When embarking on any furniture construction or upholstery project, the choice of fasteners is paramount to ensuring structural integrity and longevity. Among these, heavy-duty staples stand out as a critical component for creating robust and durable pieces. Unlike their standard counterparts, which are suited for lightweight applications like craft projects or temporary fixes, heavy-duty staples are engineered to withstand significant stress and strain. They are the invisible workhorses that hold together everything from a solid oak chair frame to the plush upholstery of a well-loved sofa. The core distinction lies in their gauge, crown width, leg length, and the material from which they are manufactured. Typically, a lower gauge number indicates a thicker, stronger staple, capable of penetrating hardwoods and dense composite materials without bending or shearing. Understanding these fundamentals is the first step toward mastering any project that demands resilience and professional-grade results.

Selecting the wrong staple can lead to a host of problems, including joint failure, material splitting, and an overall compromised finish. Therefore, a deep dive into the specifications and intended applications of these fasteners is not just recommended; it is essential. This guide will navigate you through the critical aspects of heavy duty furniture staples, from the various types available to the specific projects they are best suited for. We will also explore five key long-tail queries that often arise during the selection process, providing detailed insights to help you make an informed decision. Whether you are a seasoned professional or a dedicated DIY enthusiast, possessing a thorough knowledge of these fasteners will elevate the quality and durability of your work, ensuring that your furniture remains sturdy and beautiful for years to come.

Key Considerations for Choosing the Right Staple

Choosing the correct heavy-duty staple is a multifaceted process that goes beyond simply picking the first box you see. Several critical factors must be evaluated in tandem with your project requirements to ensure optimal performance and a flawless finish.

Material Composition and Staple Gauge

The material of the staple itself is a primary determinant of its strength and resistance to corrosion. Most heavy-duty staples are made from steel, but they can be further enhanced through coatings and plating.

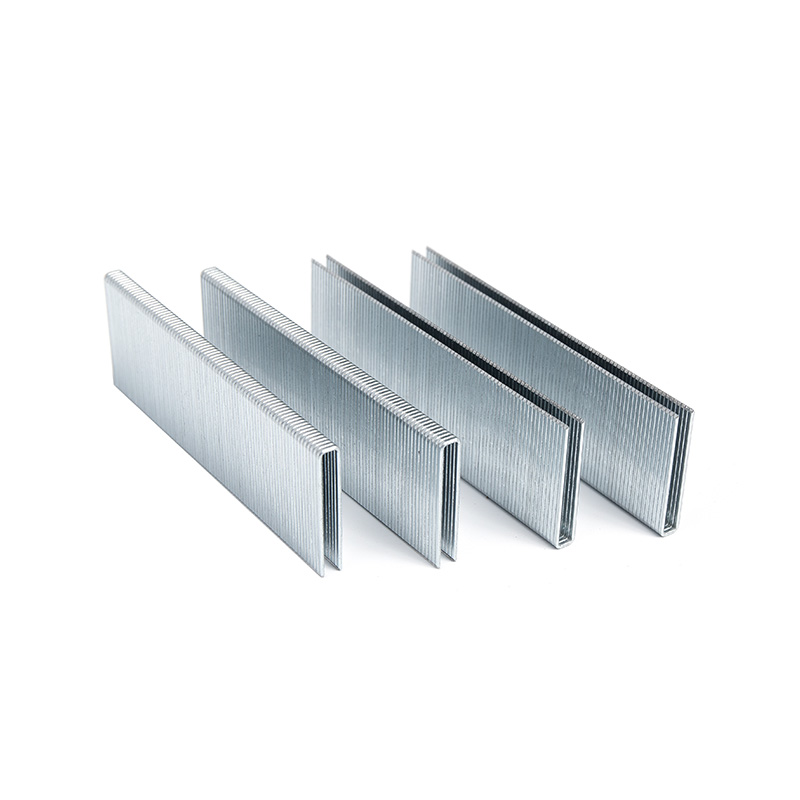

- Galvanized Staples: These are coated with a layer of zinc, which provides excellent resistance to rust and corrosion. This makes them ideal for projects that might be exposed to moisture or are intended for outdoor use.

- Stainless Steel Staples: Offering the highest level of corrosion resistance, stainless steel staples are the premium choice for environments with high humidity or for use with treated woods that can accelerate corrosion in standard staples.

- Hardened Steel Staples: These are heat-treated to increase their tensile strength, reducing the chance of the staple bending upon impact with dense materials like hardwoods or MDF.

The gauge of a staple refers to the thickness of its wire. It is a counterintuitive measurement; a lower gauge number signifies a thicker, stronger staple. For heavy-duty applications, staples typically range from 16-gauge (thick) to 20-gauge (slightly thinner but still very robust). A 16-gauge staple offers immense holding power for structural joints, while an 18 or 20-gauge staple might be preferred for securing thicker upholstery fabrics where a smaller puncture hole is desirable.

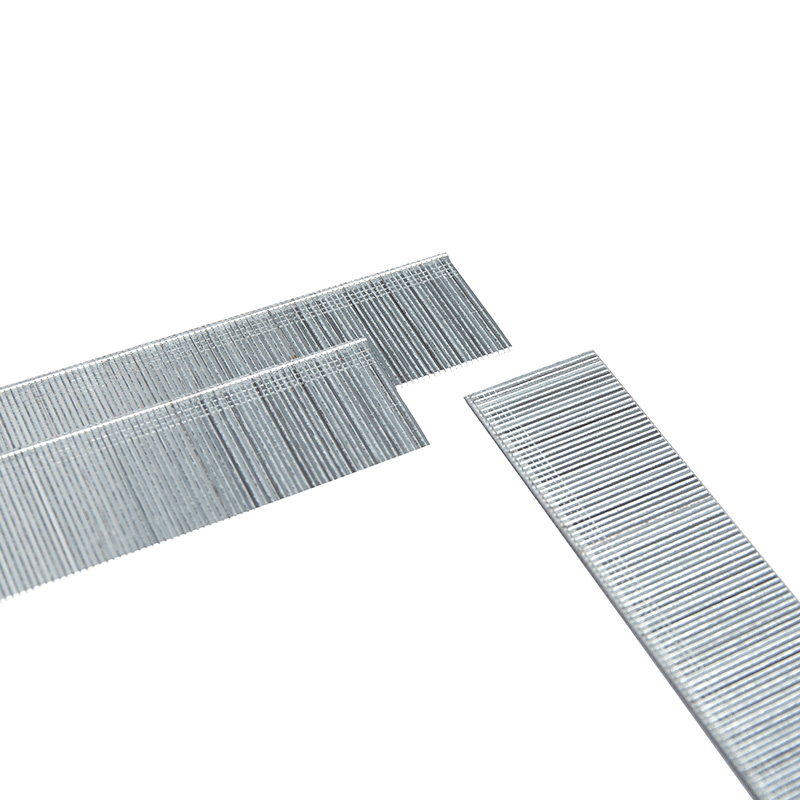

Crown Width and Leg Length

The crown is the top bridge of the staple that holds the two legs together. The width of the crown directly affects the distribution of holding force. A wider crown provides greater surface area and stability, making it excellent for securing large panels, webbing, or insulation. Common heavy-duty crown widths range from 1/4 inch to 9/16 inch.

Leg length, or depth, determines how deep the staple will penetrate into the material. It is crucial to select a leg long enough to achieve a deep, secure hold but not so long that it pierces through the other side of your workpiece. For example, attaching 1/2 inch thick upholstery foam to a 1-inch thick wood frame would require a staple with a leg length of approximately 3/8 inch to 1/2 inch to ensure it anchors firmly into the wood without breaking through the frame's surface.

Addressing Common User Queries on Heavy-Duty Staples

Both professionals and DIYers often have specific questions when searching for the perfect staple. Addressing these queries in detail can demystify the selection process and prevent common pitfalls.

best heavy duty staples for upholstery projects

Upholstery is an art that demands precision and the right tools. The best staples for upholstery must provide a strong, reliable hold without damaging the delicate fabrics or underlying materials. For most upholstery applications, a 20 or 18-gauge staple is ideal. Their thinner gauge creates a smaller hole in the fabric, reducing the risk of tearing, especially with delicate materials like silk or thin cotton. The leg length is particularly critical; it must be sufficient to penetrate through the fabric and batting and embed deeply into the wooden frame. A leg length of 3/8 inch is a versatile choice for many tasks, but thicker layers may require 1/2 inch or even 5/8 inch legs. It is also advisable to use galvanized staples for upholstery to prevent any rust stains from bleeding through light-colored fabrics over time, especially in environments with fluctuating humidity.

how to choose heavy duty staples for furniture framing

Furniture framing is the skeleton of any piece, and it requires the strongest possible fasteners to ensure structural integrity. For this demanding application, heavy duty furniture staples with a low gauge, such as 16 or 18, are non-negotiable. These thicker staples can withstand the immense pressure exerted on joint without bending during application. The leg length must be chosen based on the thickness of the wood being joined; a good rule of thumb is to select a staple whose leg length is at least three times the thickness of the thinner piece of wood being fastened. For instance, when joining two 1x2 boards (which are actually 3/4 inch thick), a staple with a 1-inch leg would provide a deep, secure hold. Hardened steel staples are highly recommended for framing to prevent bending and ensure consistent driving into hardwoods like oak or maple.

difference between standard and heavy duty furniture staples

Understanding the difference between standard and heavy-duty staples is crucial for project success. The disparity is not merely in name but in their physical properties and intended use. The following comparison outlines the key distinctions:

Standard staples are designed for light-duty tasks and are typically constructed from thinner, higher-gauge wire (e.g., 21-gauge or higher). They have a smaller crown width and shorter leg length, making them suitable for attaching thin fabrics, paper, or very softwoods. In contrast, heavy-duty staples are built for demanding applications. They feature a lower gauge (thicker wire), such as 16 or 18, providing significantly greater shear and tensile strength. Their larger crown width distributes force more effectively, and their longer legs allow for deeper penetration into dense materials. Using a standard staple for a heavy-duty task will almost certainly result in fastener failure, potentially damaging your workpiece and compromising the entire project.

| Feature | Standard Staples | Heavy-Duty Staples |

|---|---|---|

| Wire Gauge | 21-Gauge or higher (thinner wire) | 16 to 20-Gauge (thicker wire) |

| Primary Use | Light crafts, temporary fixes, thin materials | Furniture framing, upholstery, structural work |

| Material Strength | Standard steel, prone to bending | Hardened or galvanized steel, high resistance to bending |

| Holding Power | Low to moderate | Very high |

what size heavy duty staples for upholstery

Selecting the correct size is perhaps the most common point of confusion. The "size" of a staple is a combination of its crown width and leg length (e.g., 1/4" x 3/8"). For upholstery, the size is predominantly determined by the layers of material you need to penetrate. A common and versatile size for general upholstery work, including attaching fabric and batting to frames, is a 1/4" crown with a 3/8" leg. For thicker materials, such as multiple layers of foam or webbing, a longer leg is necessary. A 1/4" crown with a 1/2" or 5/8" leg would be more appropriate. If you are working on a project involving deep button tufting or need to secure springs, you might even require staples with a 5/16" or 3/8" crown for added holding power. Always test a staple on a scrap piece of your frame and material to ensure the size provides a secure hold without causing splitting or visible penetration through the fabric.

heavy duty staples for outdoor furniture repair

Outdoor furniture repair presents a unique set of challenges, primarily due to constant exposure to the elements. Moisture, temperature fluctuations, and UV radiation can quickly degrade standard fasteners. Therefore, the choice of staple is critical for a lasting repair. The absolute best choice for any outdoor furniture project is stainless steel staples. While more expensive, they offer unparalleled resistance to rust and corrosion, ensuring that the fasteners will not weaken or stain the furniture over time. If stainless steel is not an option, heavy-duty galvanized staples with a thick zinc coating are a suitable alternative. In terms of size, assess the repair need: reattaching a synthetic wicker strand might require a fine 20-gauge staple, while repairing a loose joint on a Adirondack chair would demand a robust 16-gauge staple with a long leg length to bite into the weathered wood effectively. Always ensure the staple is compatible with your pneumatic or electric stapler to avoid jams and ensure smooth operation.

Advanced Techniques and Best Practices

Beyond selecting the right staple, proper technique is vital for achieving professional results. Mastering these advanced practices will significantly improve the quality and durability of your work.

Proper Staple Placement and Pattern

How and where you place staples can be as important as the staple itself. For structural framing, staples should be placed in a staggered pattern rather than in a single straight line. This distributes the stress across a wider area of the wood, preventing splitting and creating a stronger joint. When upholstering, staples should be placed approximately every 1 to 2 inches apart, depending on the tension of the fabric. Start by placing a staple in the center of a side, then move to the opposite side and pull the fabric taut before placing another staple. Work your way outwards towards the corners, alternating sides to maintain even tension. This method prevents the fabric from being pulled unevenly, which can lead to wrinkles or a distorted pattern.

Avoiding Common Mistakes

Even experienced craftsmen can make mistakes. Being aware of common errors can help you avoid them:

- Using the Wrong Staple Gun: Ensure your stapler is rated for the gauge and length of staple you are using. Mismatching can cause constant jamming and inconsistent driving depth.

- Ignoring Material Density: Failing to adjust air pressure (on pneumatic staplers) for harder woods will result in staples that are not fully driven, sitting proud of the surface and creating a weak hold.

- Splitting Wood: This often occurs when stapling too close to the end of a board or using a leg length that is too long for the material. Drilling a small pilot hole can often prevent splitting in vulnerable areas.

- Overdriving Staples: Too much pressure can drive the staple too deep, crushing the material around it and reducing its holding power. Adjust the drive depth on your tool if possible.