As global e-commerce logistics and modern furniture manufacturing continue to expand, the market is placing unprecedented demands on the durability and precision of terminal packaging materials. Recently, the 80 Series High-Strength U-Type Staple (Model 8010) has emerged as a "hidden champion" in the packaging and upholstery sectors, recognized for its superior penetration power and structural stability.

Redefining Strength: Eliminating "Weak Links"

In traditional carton sealing or light furniture upholstery, standard staples often suffer from insufficient hardness, leading to "jamming" or "buckling." This not only affects the aesthetic finish but also risks packaging failure during transit.

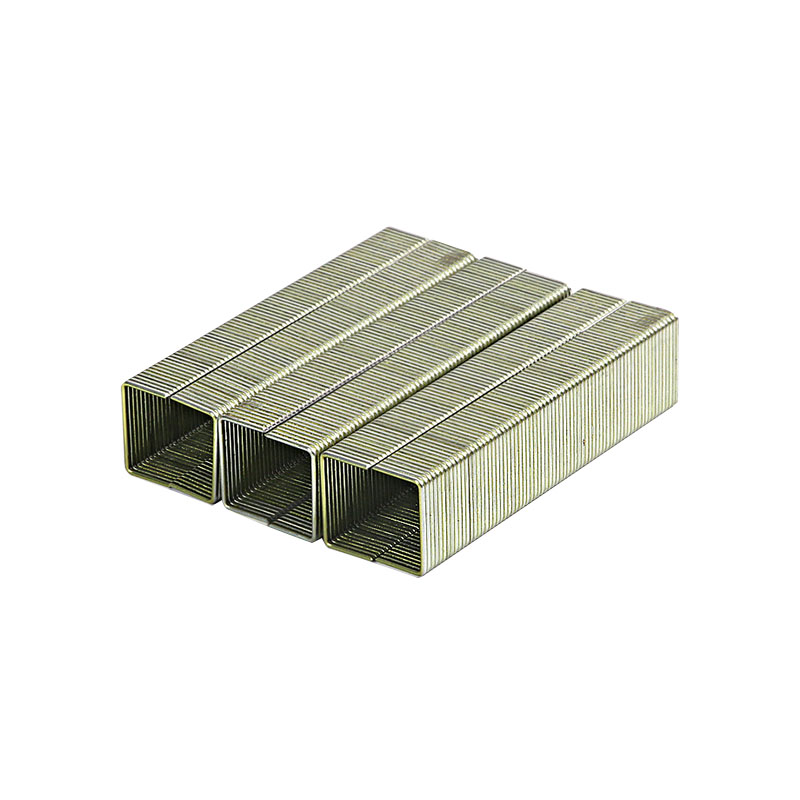

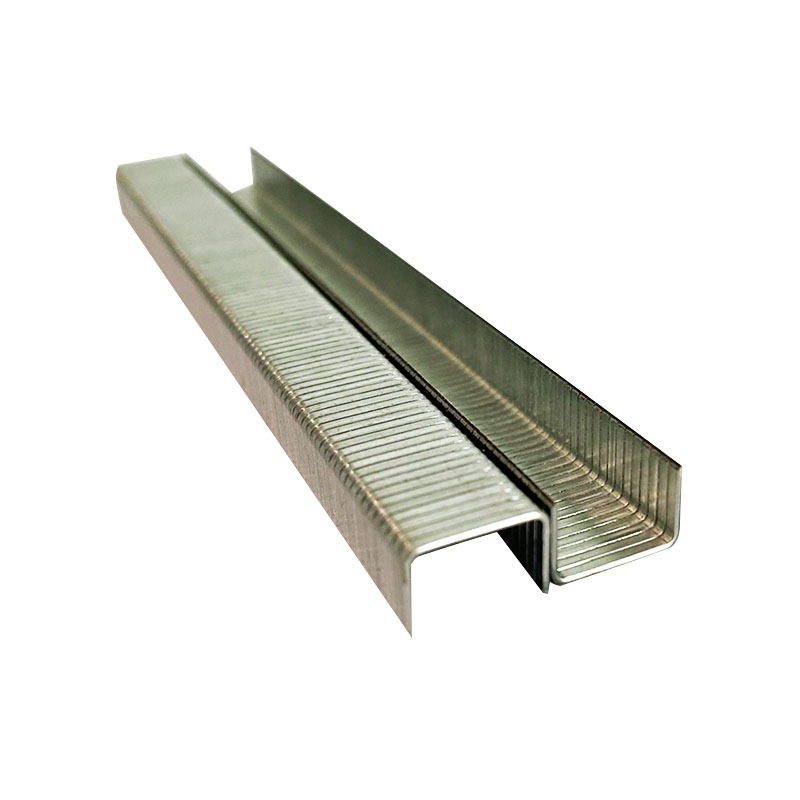

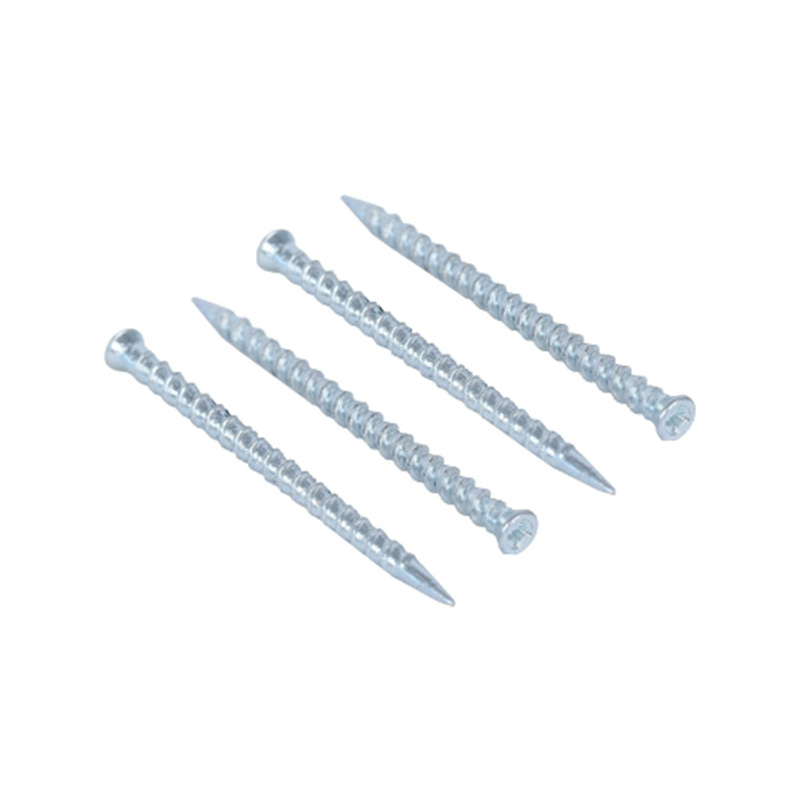

The newly refined 8010 U-Type Staple is engineered to solve these pain points. Manufactured from premium galvanized wire, it offers core advantages:

-

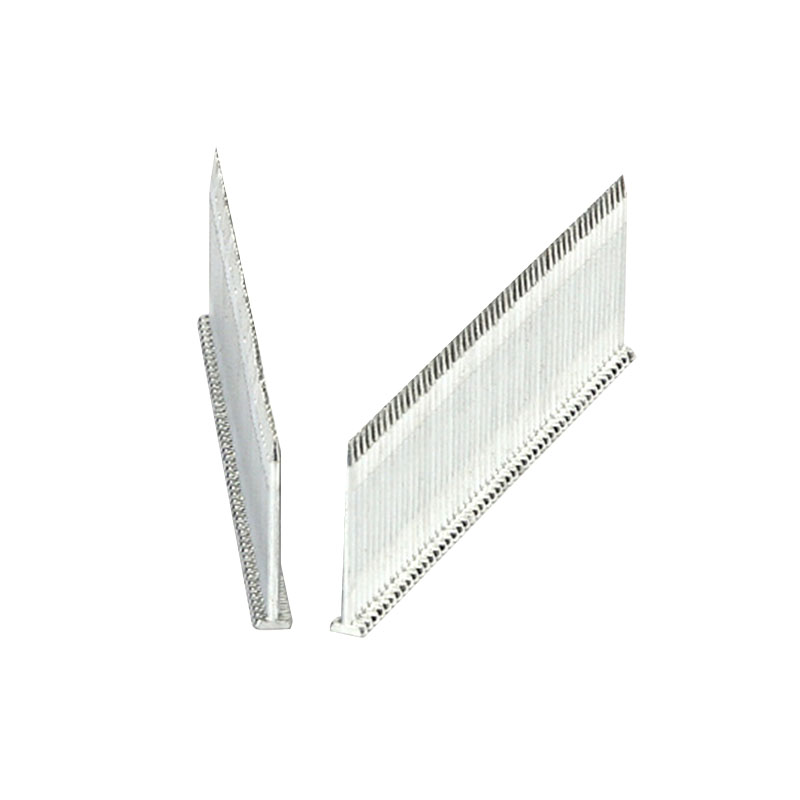

Superior Tensile Strength: Compared to standard market options, the wire hardness is significantly optimized. It delivers one-shot precision penetration through thick corrugated cardboard or high-density fiberboard without bending or breaking.

-

Precision Engineering: The 80 Series standard crown width, combined with the "Golden Ratio" 10mm leg length, ensures smooth operation in various pneumatic staplers. This drastically reduces gun jamming rates and boosts assembly line efficiency.

-

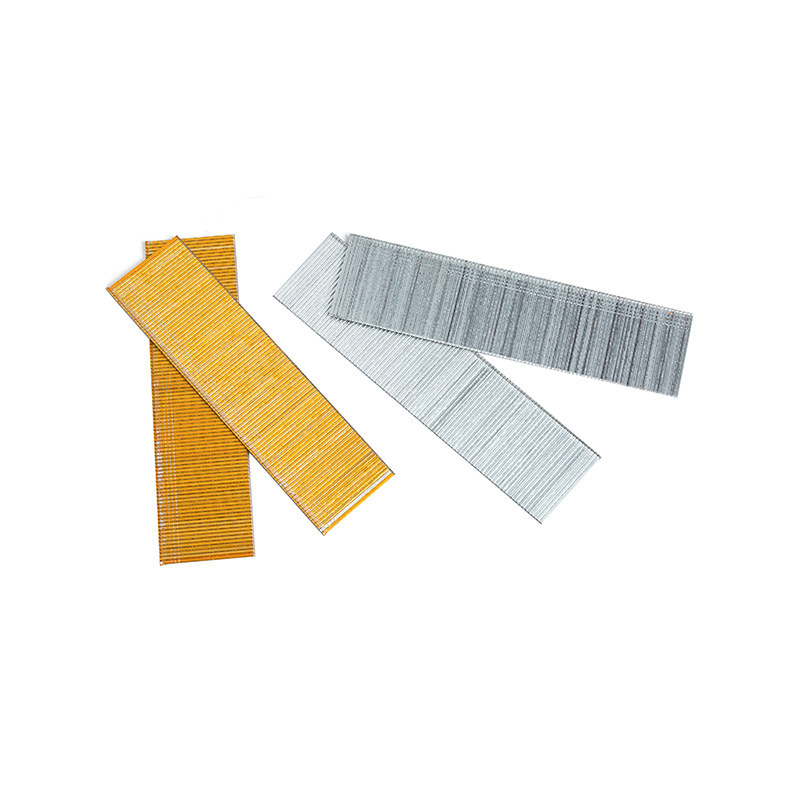

Corrosion Resistance: The specialized galvanized finish effectively withstands humid storage and shipping environments, preventing rust stains on cardboard or fabric.

Versatile Applications & Cost-Effectiveness

Industry experts note that while a staple is a small component, its quality directly impacts the safety of the "Last Mile" delivery. The 8010 Model, with its versatile dimensions, has proven essential across multiple scenarios:

-

Logistics Packaging: Ideal for secure bottom and top sealing of courier cartons.

-

Home Furnishings: Widely used in sofa upholstery, chair backing, and exhibition stand assembly.

-

Automotive Interiors: trusted for fixing headliners and seat leather.

Industry Outlook

As companies increasingly pivot towards Lean Manufacturing, high-quality consumables like the 80 Series 8010 are replacing cheaper, inferior alternatives. They are fast becoming the standard configuration for brands that refuse to compromise on packaging integrity and production speed.