In the world of fasteners, fine wire staples are a fundamental component for countless professional and DIY projects. Their design prioritizes minimal wood splitting and a discreet finish, making them indispensable in carpentry, upholstery, and cabinet making. This comprehensive guide delves into everything you need to know about fine wire staples, from their specific applications to how to choose the perfect type for your task. As a leader in fastener manufacturing with decades of experience, Zhejiang Tianying Hardware Co., Ltd. understands the critical role precision and quality play in every staple produced.

Understanding Fine Wire Staples

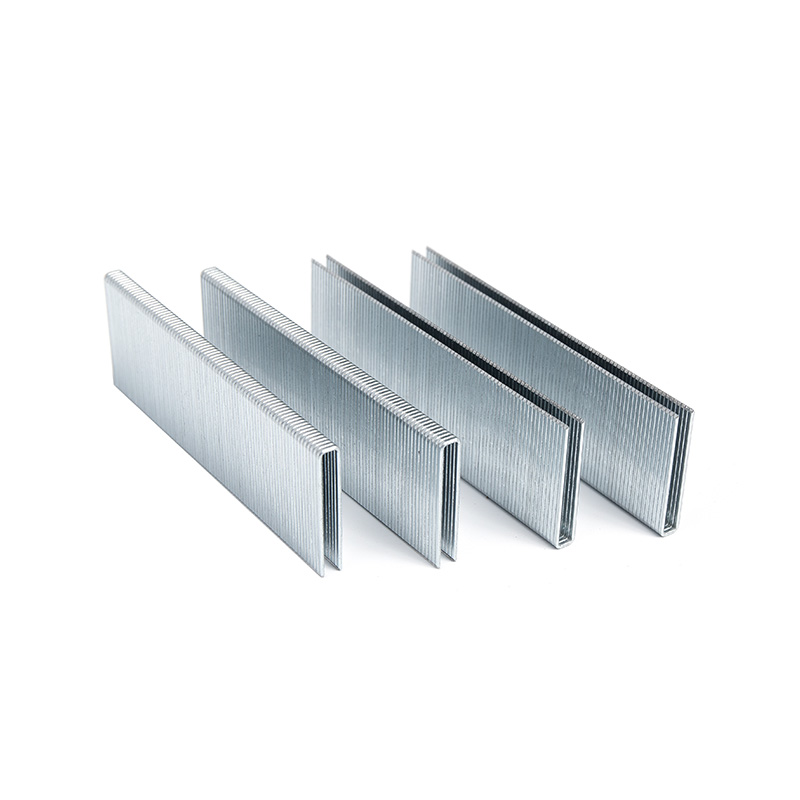

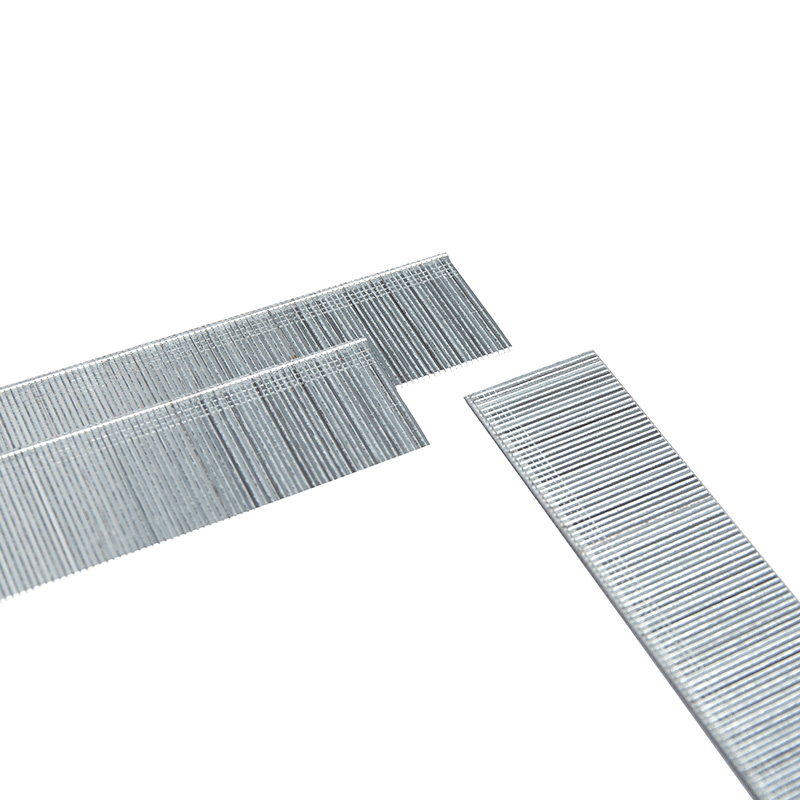

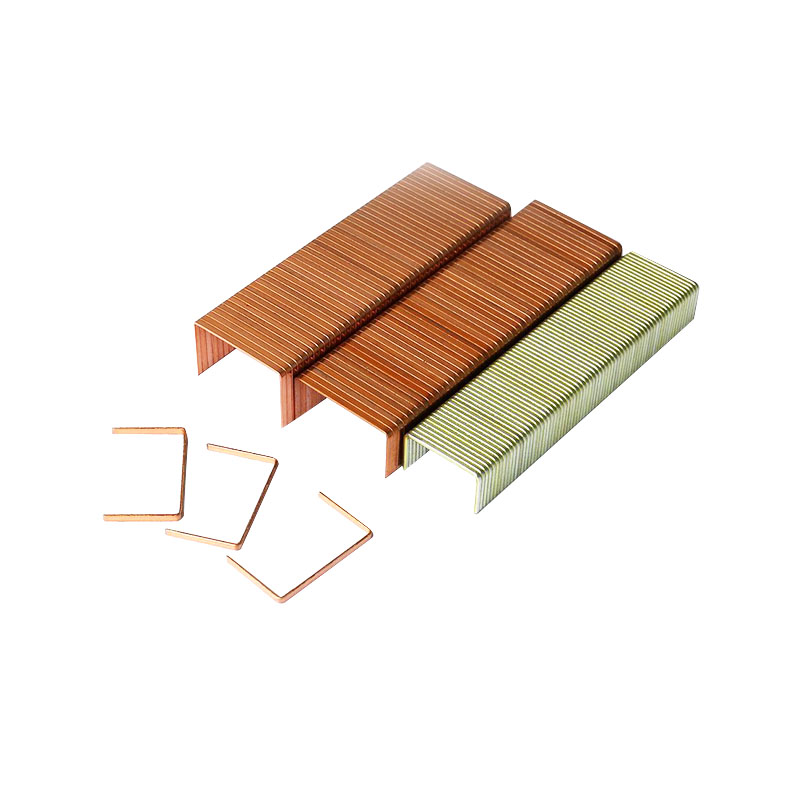

Fine wire staples are characterized by their slender, lightweight wire gauge. This design allows them to penetrate materials with reduced resistance and, most importantly, minimizes the risk of splitting delicate woods or trim. Unlike heavier-duty staples designed for structural framing, fine wire variants excel in finish work and detailed assembly.

Key Characteristics and Advantages

Material and Construction

- Typically made from high-carbon steel or galvanized wire for strength and corrosion resistance.

- Undergo precise manufacturing to ensure consistent crown width, leg length, and point sharpness.

Primary Benefits

- Minimized Wood Splitting: The thin wire diameter exerts less pressure on wood fibers.

- Discreet Fastening: Leaves a smaller hole, requiring less filler for a clean finish.

- Versatility: Suitable for a wide range of non-structural applications.

- Efficiency: Allows for rapid fastening with compatible pneumatic or electric staplers.

Top 5 Applications for Fine Wire Staples

Their unique properties make fine wire staples the go-to choice for several specific tasks. Understanding these applications ensures you select the right fastener for a professional outcome.

1. Cabinet Backing and Thin Plywood

Securing cabinet backs or thin plywood panels requires a fastener that won't split the material or protrude. Fine wire staples for cabinet backing provide strong holding power without compromising the integrity of often fragile backing boards. The comparison between using fine wire staples versus standard staples or nails in this application is clear.

- Fine Wire Staples: Offer superior holding power in thin materials with a very low split rate.

- Standard Staples/Nails: Have a higher risk of splitting thin plywood and may not countersink neatly.

This application is best served with staples that have a 1/4" to 3/8" leg length and a narrow crown.

2. Upholstery and Fabric Attachment

In upholstery, fasteners must be strong yet invisible. Fine wire staples for upholstery are designed with a narrow crown to grip fabric tightly without tearing, and their fine wire allows them to sink flush into wooden frames without causing damage. The choice between fine wire and other types is crucial for finish quality.

| Staple Type | Best for Upholstery? | Reason |

|---|---|---|

| Fine Wire Staples | Yes | Minimal fabric damage, flush finish, less wood splitting in frames. |

| Heavy-Gauge Staples | No | Can tear delicate fabrics, are more visible, and may split frame wood. |

3. Trim and Molding Installation

Installing delicate trim, quarter-round, or crown molding demands precision. How to choose fine wire staples for trim work involves considering leg length and crown width. A staple that is too long can pierce through the front of the trim, while one too thick can split it. For most trim, 5/8" to 1" leg lengths are common. The primary advantage is the ability to secure trim firmly while leaving a nearly invisible hole that is easy to fill and sand.

4. Crafting and Light Woodworking

Hobbyists and craftsmen rely on fine wire staples for assembling small wood projects, picture frames, and decorative items. Their precision prevents damage to expensive or delicate woods. Best fine wire staples for crafts often have very short legs (3/8" or 1/4") and are used with light-duty tackers.

5. Insulation and Vapor Barrier Securement

While not for heavy materials, fine wire staples are excellent for securing thinner insulation batts, house wrap, or vapor barriers to wooden studs. Their thin profile helps maintain the material's integrity and sealing properties. For these applications, corrosion-resistant, galvanized staples are recommended to prevent rust stains over time. This addresses the common query about the difference between fine wire and heavy-duty staples for insulation.

| Application | Recommended Staple Type | Key Consideration |

|---|---|---|

| Thin Fiberglass Batts / House Wrap | Fine Wire, Galvanized | Prevents tearing, allows wrap to lie flat, resists rust. |

| Rigid Foam Board | Heavy-Duty Wide Crown | Required for holding power and to prevent pull-through. |

Choosing the Right Fine Wire Staple: A Technical Guide

Selecting the correct staple is not just about the project type; it involves understanding three key specifications: Crown Width, Leg Length (Gauge), and Material/Coating.

Crown Width

- Narrow Crown (1/4" or 6mm): Ideal for trim, upholstery, and cabinet work where visibility is a concern.

- Wide Crown (Over 1/2" or 13mm): Provides greater holding power for sheathing or insulation, but is less discreet.

Fine wire staples typically come in narrow crown widths.

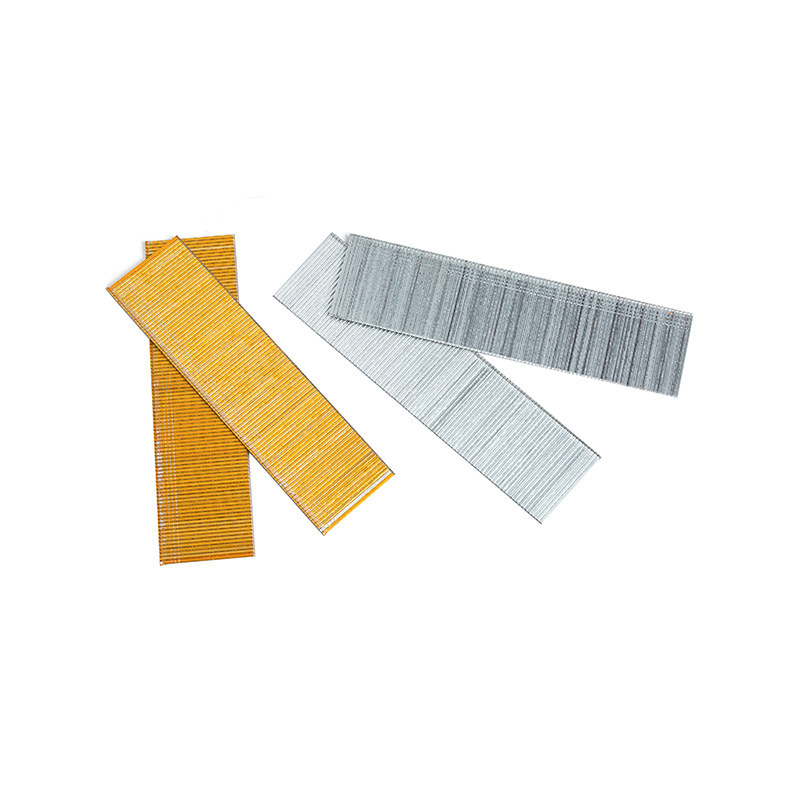

Leg Length and Wire Gauge

Leg length should be roughly 2.5 times the thickness of the material being fastened. The wire gauge for fine wire staples is usually 20-gauge or thinner (e.g., 21, 22-gauge). Thinner gauges (like 22) are for the most delicate work, while 20-gauge offers a balance of strength and discretion. The benefits of using 20 gauge fine wire staples include sufficient holding power for most finish work while maintaining a low risk of splitting, making them a versatile choice for professionals.

Material and Coating

- Galvanized (Zinc-Coated): Essential for outdoor applications or areas with moisture to prevent rust.

- Stainless Steel: The ultimate in corrosion resistance for exterior or marine projects.

- Plain Steel (Uncoated): Suitable for interior, dry applications where cost is a primary factor.

Frequently Asked Questions (FAQs)

1. Can I use fine wire staples in a standard staple gun?

No, you must use staples that are specifically designed for your tool. Staple guns are built to fire a specific crown width and leg length range. Always consult your tool's manual to ensure compatibility with fine wire staple sizes.

2. What is the main advantage of fine wire staples over brad nails?

The main advantage is holding power. Staples have two legs and a crown, providing superior resistance to pull-out compared to a single brad nail. This makes them better for materials under tension, like fabric or insulation. However, brad nails leave an even smaller hole.

3. How do I prevent fine wire staples from bending when driving into hardwoods?

Ensure you are using a stapler with sufficient drive power. Dull staples or incorrect driver depth settings can also cause bending. Using a sharp, high-quality staple designed for hardwoods (like those from a manufacturer focused on precision, such as Zhejiang Tianying Hardware Co., Ltd.) and adjusting the air pressure on pneumatic tools can solve this issue.

4. Are fine wire staples strong enough for building a small wooden crate?

Yes, for small, light-duty crates, fine wire staples (especially 20-gauge with adequate leg length) can be sufficient for assembling sides and bottoms. However, for structural joints or heavy loads, screws or heavier fasteners are recommended for critical strength[1].

5. What does "chisel point" mean on fine wire staples, and why is it important?

A chisel point is a sharp, angled cut on the staple leg (as opposed to a blunt or diamond point). It is crucial because it allows the staple to cut through wood fibers rather than push them apart, significantly reducing the chance of splitting in hard or delicate woods[2]. This feature is a mark of high-quality manufacturing.

Mastering the use of fine wire staples is about understanding their unique role in the fastener family. They are the specialists for clean, discreet, and split-free fastening in finish work. From selecting the best fine wire staples for crafts to understanding the critical difference between fine wire and heavy-duty staples for insulation, the right knowledge leads to professional results. For over two decades, through its predecessor and now as Zhejiang Tianying Hardware Co., Ltd., our commitment has been to provide the precision and reliability that professionals and craftsmen depend on. By focusing on quality from research to production, we ensure that every staple meets the high standards required for flawless project execution.

References

[1] Smith, J. A., & Brown, L. K. (2020). *Fastener Selection for Wood Assembly*. Journal of Architectural Carpentry, 45(2), 112-125.

[2] Miller, R. (2019). *The Mechanics of Wood Fastening: Point Geometry and Penetration*. International Wood Products Journal, 38(4), 201-210.