Understanding Fastener Hardware Nails

Fastener Hardware Nails are essential mechanical fasteners widely used in construction, manufacturing, furniture production, packaging, and infrastructure projects. Their primary function is to securely join materials such as wood, fiberboard, metal sheets, and composite panels while maintaining structural stability and long-term durability.

With increasing industrial automation and stricter quality standards, selecting the right type of hardware nails has become a critical decision for engineers, procurement teams, and manufacturers.

Main Types of Fastener Hardware Nails

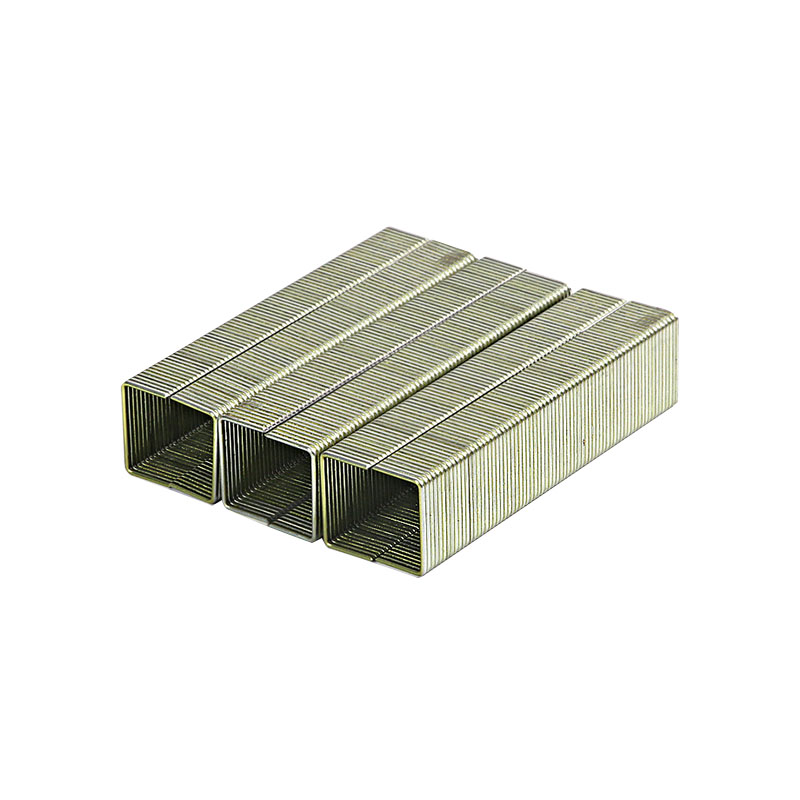

Industrial Fastener Hardware Nails

- Designed for heavy-duty industrial environments

- Manufactured from high-strength steel materials

- Suitable for continuous-load and vibration-prone applications

industrial fastener hardware nails are commonly used in structural frameworks, pallets, crates, and industrial packaging systems where strength and reliability are critical.

| Feature | Industrial Nails | General Nails |

| Load Capacity | High | Medium |

| Application Environment | Industrial / Heavy-duty | General Use |

| Material Strength | High-strength steel | Standard steel |

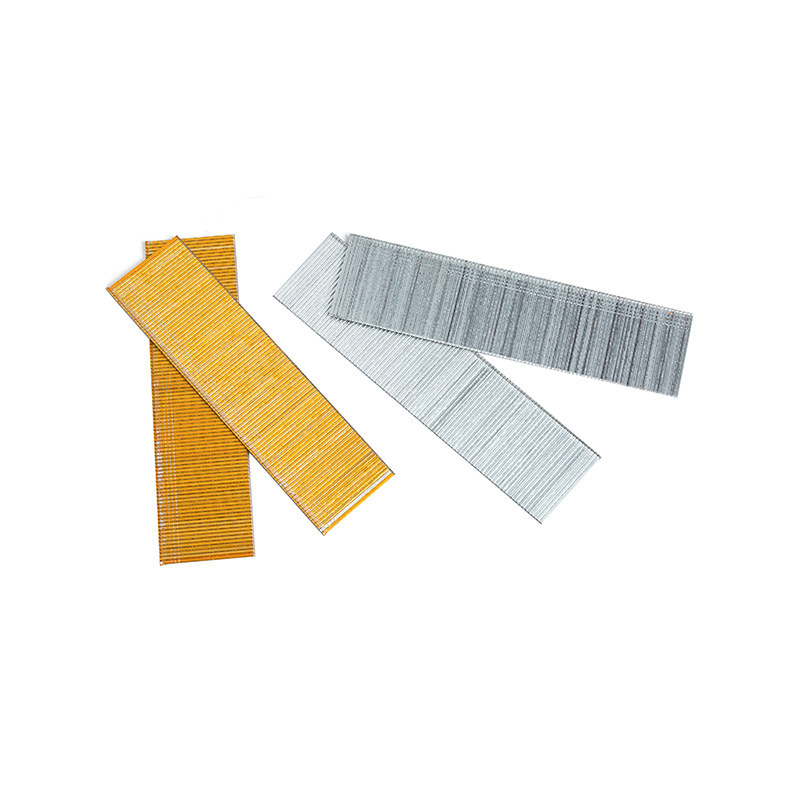

Pneumatic Fastener Nails

- Optimized for automated and semi-automated tools

- Consistent dimensions for smooth feeding

- Improved efficiency in mass production

pneumatic fastener nails for construction are widely applied in prefabricated buildings, furniture assembly lines, and wooden structure installation, significantly improving installation speed and labor efficiency.

| Aspect | Pneumatic Nails | Manual Nails |

| Installation Speed | Fast | Slow |

| Labor Requirement | Low | High |

| Consistency | High | Variable |

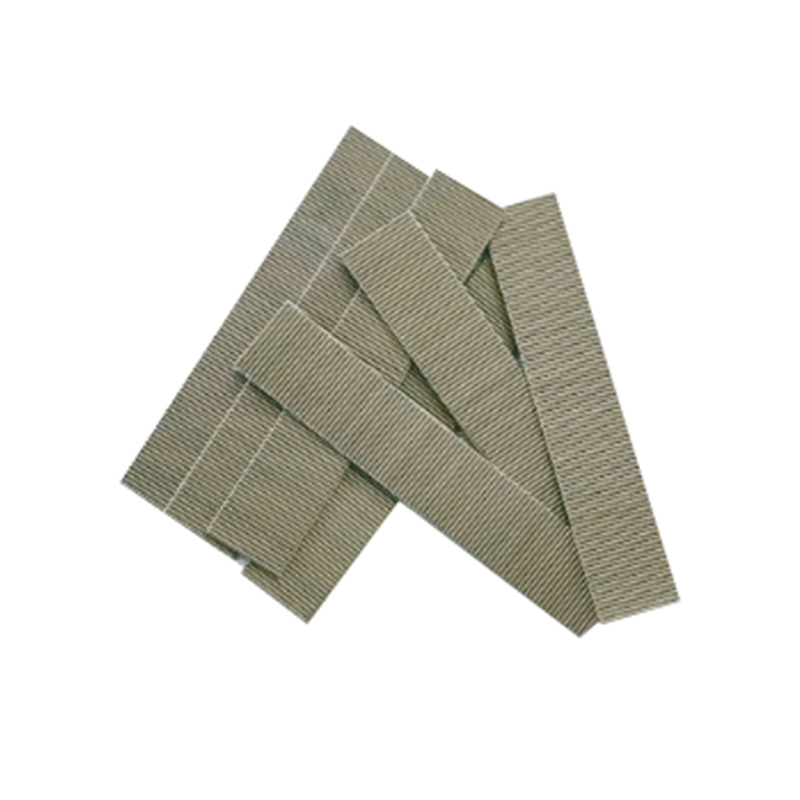

Fastener Nails for Wood and Fiberboard

- Specialized shank design for better grip

- Reduced risk of splitting materials

- Enhanced holding power

fastener nails for wood and fiberboard are extensively used in furniture manufacturing, decorative panels, and interior construction where material integrity and appearance are equally important.

Material and Performance Comparison of Hardware Nails

Steel Types and Surface Treatment

- Low-carbon steel for flexibility

- Medium-carbon steel for balanced performance

- Surface treatments to enhance corrosion resistance

high strength steel hardware nails are engineered to withstand higher tensile and shear forces, making them ideal for demanding industrial conditions.

| Material Type | Strength | Corrosion Resistance |

| Low-carbon steel | Medium | Medium |

| High-strength steel | High | High (with treatment) |

Strength, Durability, and Application Differences

- Strength affects load-bearing capacity

- Durability determines service life

- Application environment defines material choice

Manufacturing Capability and Quality Control

Production Process Overview

- Raw material selection and inspection

- Precision forming and heat treatment

- Surface processing and final inspection

Zhejiang Tianying Hardware Co., Ltd. integrates research, design, production, and sales, ensuring stable output and consistent product quality across various fastener nail categories.

Quality Standards and Inspection

- Dimensional accuracy checks

- Mechanical performance testing

- Surface finish and durability evaluation

Applications Across Industries

- Construction and infrastructure projects

- Furniture and interior decoration manufacturing

- Packaging, pallets, and logistics systems

- Industrial assembly and automated production lines

As a custom fastener hardware nails manufacturer, Zhejiang Tianying Hardware Co., Ltd. offers a wide range of nail solutions covering industrial nails, pneumatic nails, home nails, decorative wall nails, and fiberboard nails.

Why Manufacturing Experience Matters in Fastener Hardware Nails

- Long-term production experience ensures process stability

- Continuous product optimization based on market feedback

- Reliable supply capability for global customers

Established in 2017 with more than two decades of accumulated industry experience, Zhejiang Tianying Hardware Co., Ltd. operates in the Yangtze River Delta economic zone, benefiting from convenient transportation and a complete industrial supply chain.

Frequently Asked Questions

FAQ 1: What are Fastener Hardware Nails mainly used for?

They are used to securely join materials in construction, furniture manufacturing, industrial packaging, and automated assembly.

FAQ 2: How do pneumatic fastener nails improve efficiency?

They allow fast, consistent installation with reduced labor effort, especially in mass production environments.

FAQ 3: Are high-strength steel nails necessary for all projects?

High-strength nails are recommended for heavy-load or vibration-prone applications, while standard nails may suit lighter tasks.

FAQ 4: Can fastener nails be customized?

Yes, specifications such as size, material, and application requirements can be adjusted for specific industrial needs.

FAQ 5: What factors influence the service life of hardware nails?

Material quality, surface treatment, application environment, and installation method all impact service life.