Understanding Your Construction Needs

Assessing the Material: Wood, Concrete, or Steel

When planning a construction project, the first critical step is to assess the type of material you'll be fastening into. Choosing the correct type of fastener hardware nails depends heavily on whether you're working with wood framing, concrete slabs, or structural steel. For example, in wood framing you might use standard nails or ring-shank nails, while for concrete you need to consider concrete-specific fasteners. You should also evaluate characteristics like grain direction in wood or density in concrete, because these will influence how well the nail holds and whether special designs (like fluted or spiral shanks) are needed.

- Wood – requires nails that balance grip and splitting risk.

- Concrete – demands specialized concrete nails or fasteners rated for masonry.

- Steel – may require nails or fasteners designed for driven into metal or used with pre-drilling.

Evaluating Environmental Conditions

The environment in which your structure will reside affects the choice of fastener hardware nails more than many realize. Moisture, temperature fluctuations, and exposure to corrosive elements (salt air, chemical agents) all determine whether a conventional nail will suffice or if a more robust, corrosion-resistant option is necessary. For outdoor or coastal projects especially, opting for nails with protective coatings or made from inherently durable materials can dramatically increase lifespan and structural integrity.

- High humidity or moisture – consider galvanized or stainless steel nails.

- Extreme temperatures – evaluate expansion, contraction, and material fatigue.

- Exposure to chemicals – select chemically resistant metal finishes.

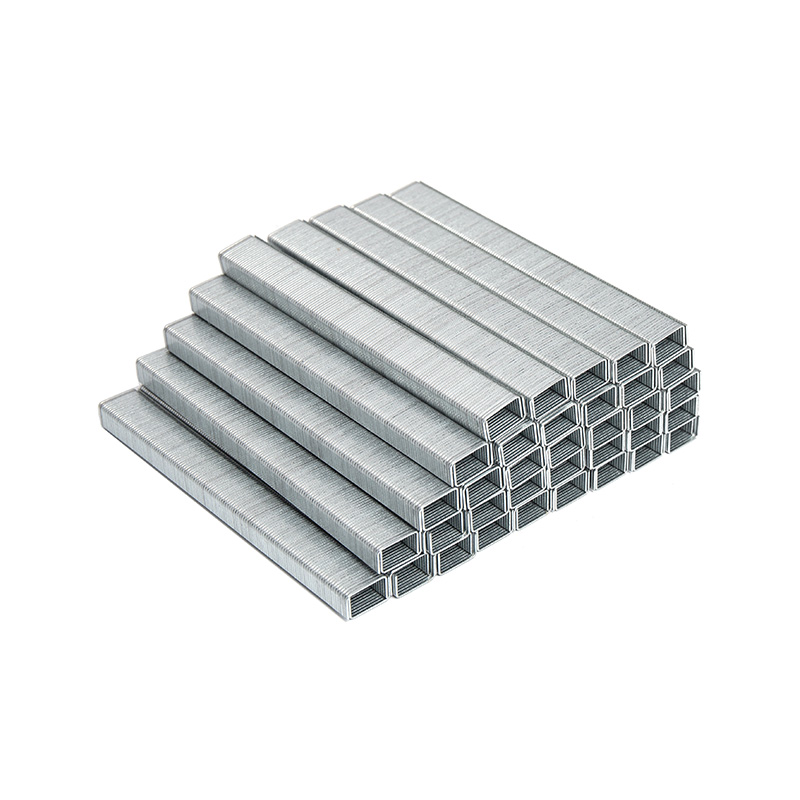

Types of Fastener Hardware Nails

Common Nails vs. Box Nails

There are various basic types of fastener hardware nails in construction, with common nails and box nails being among the most frequently used. Common nails have a relatively thick shank and a large head, offering strong holding strength for general framing work. Box nails, on the other hand, are thinner and often used in more delicate woodwork because they reduce the risk of splitting.

- Common nails – robust, suited for heavy framing and structural tasks.

- Box nails – ideal for thinner lumber, trim or finish work where splitting is a concern.

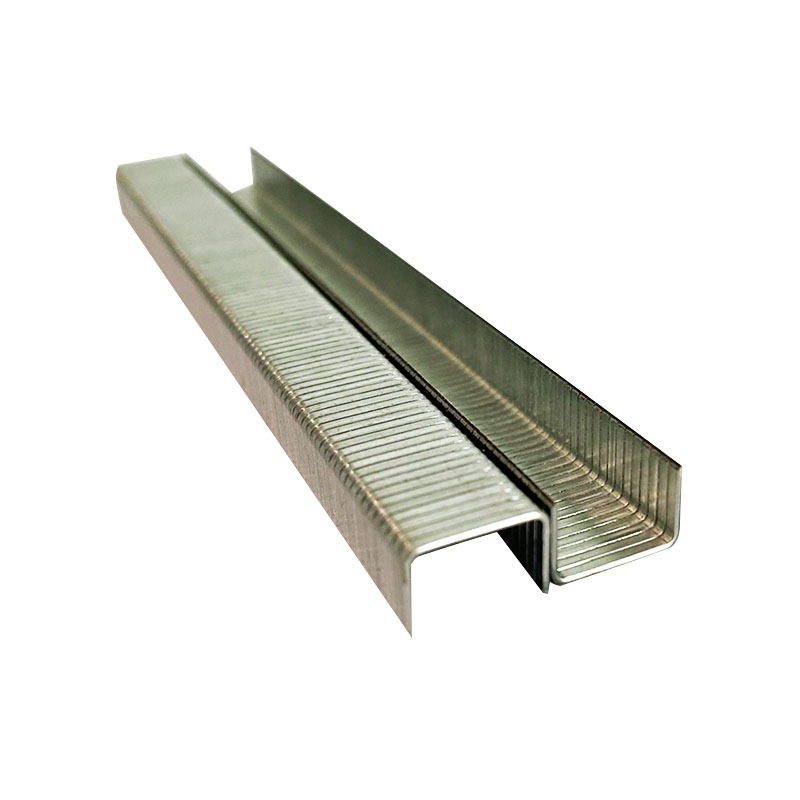

Ring-Shank Nails — High Holding Power

For projects that demand extra holding strength, you may want to use ring-shank nails. These nails feature ridges or ring-shaped patterns along the shank, increasing friction in the substrate. This design makes them especially suitable for high-stress applications, such as decking or subflooring, where shear forces or repeated movement could loosen ordinary nails.

- Enhanced grip via mechanical interlock with the material.

- Reduced loosening over time, thanks to the ringed design.

- Often used in applications where nails are subject to vibration or load—like decks, flooring, or sheathing.

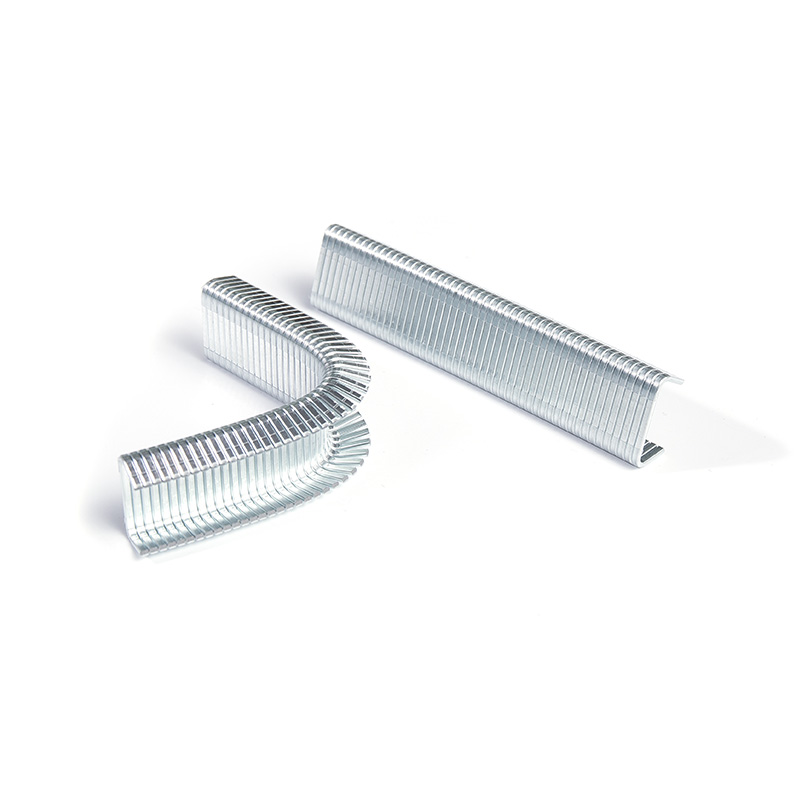

Special-Purpose Nails: Concrete, Stainless Steel, Galvanized

Beyond traditional nails, construction often requires specialized fasteners to handle specific challenges. Using the right type of fastener hardware nails for these purposes can make a big difference in durability and safety.

- Concrete nails – hardened and often designed to penetrate masonry or concrete.

- Galvanized nails – coated in zinc to resist rust, ideal for damp environments.

- Stainless steel nails – excellent for highly corrosive environments like coastal areas.

Material Considerations

Why Choose Galvanized Fastener Hardware Nails

Galvanized fastener hardware nails are coated with a layer of zinc that protects the steel core from oxidizing, significantly improving resistance to rust. In outdoor construction or any moist environment, this coating helps ensure long-term performance. However, it's important to weigh the benefits against potential trade-offs: zinc-coated nails cost more than bare steel, and if the coating is scratched or damaged during installation, the underlying metal may still corrode.

- Excellent for environments prone to moisture or dampness.

- Widely available and cost-effective compared to more exotic materials.

- Potential downsides: coating damage or limited longevity in very harsh chemical environments.

Advantages of Stainless Steel Nails

When you need maximum corrosion resistance, stainless steel fastener hardware nails offer superior performance. They resist rust far more effectively than galvanized nails and are often specified for marine construction, coastal structures, or high-end outdoor projects. Stainless steel nails typically come in grades like 304 or 316, each offering different levels of resistance, but they also come with a higher upfront cost. For many projects, the extended lifespan and reduced maintenance needs justify the investment.

- Exceptional corrosion resistance—even in salt-rich or chemical environments.

- Long-term durability reduces need for replacement.

- Higher material cost but often lower lifecycle cost.

Cost vs. Durability Trade-offs

Deciding between cheaper nails and more premium materials is a balancing act. While uncoated steel nails may be the least expensive initially, they may fail or corrode faster in harsh conditions, leading to higher maintenance or replacement costs. On the other hand, investing in galvanized or stainless steel nails can reduce long-term risk but requires a higher up-front outlay.

- Uncoated nails: low initial cost, potentially high maintenance.

- Galvanized: moderate cost, good corrosion protection.

- Stainless: highest cost, but best long-term performance.

Installation Factors

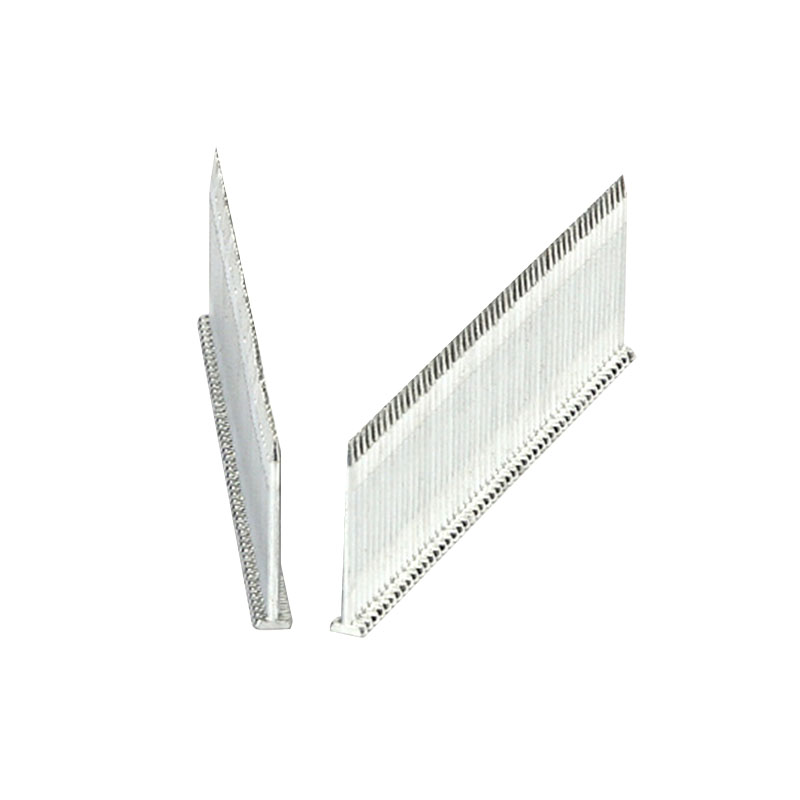

Nail Length, Diameter, and Shank Design

When selecting fastener hardware nails for your project, it's not just about material. The nail’s **length**, **diameter**, and **shank design** play vital roles in ensuring proper performance. A nail that's too short or too thin may not provide sufficient holding power, while one that's too large can damage the substrate. Similarly, the shank design affects how the load is distributed and how resistant the nail is to pull-out.

- Length: Ensure penetration into the base material without over-driving.

- Diameter: Balance between strength and minimizing material splitting.

- Shank: Smooth for general use, ring or spiral for higher grip.

Proper Tools and Techniques for Different Nail Types

Even the best-quality fastener hardware nails can fail if not installed properly. Using the right tool (hammer, nail gun) and technique matters. Also, pre-drilling may be required for dense materials like concrete, or to prevent splitting in hardwoods. For ring-shank or specialty nails, it’s especially important to control the driving speed and force to avoid damaging either the nail or the workpiece.

- Use nail guns for high-volume or repetitive work.

- Hammer-driving may be better for delicate or precise installations.

- Pre-drill holes for dense or brittle materials.

- Ensure proper safety gear: goggles, gloves, ear protection.

Performance and Safety

Corrosion Resistance in Fasteners

For long-term integrity, consider how your chosen fastener hardware nails will respond to environmental stressors. Corrosion isn’t just a cosmetic issue — it can weaken the nail, compromise structural safety, and ultimately lead to failure. Applying this consideration helps in selecting nails for specific conditions, particularly when the structure is exposed to moisture, chemicals, or salt-laden air.

- Galvanized nails protect via sacrificial zinc barrier.

- Stainless steel provides inherent resistance without coatings.

- Periodic inspections may be necessary to check for rust or degradation.

Load-Bearing and Structural Integrity

The right fastener hardware nails must meet the structural demands of your project. Nails used in load-bearing applications need to provide sufficient shear and pull-out strength. Wrong choices can lead to loosened joints, structural instability, or safety hazards. Engineers and builders must check the specifications (often provided by code or manufacturer) to confirm that the nails' mechanical performance aligns with the project requirements.

- Ring-shank nails often offer greater resistance to pull-out.

- Choose nails rated for shear load if they’ll bear lateral forces.

- Use proper layout and spacing to distribute loads evenly.

Cost-Effectiveness and Lifecycle

Initial Cost vs Long-Term Maintenance

When budgeting for fastener hardware nails in construction, consider not just the upfront cost but the entire lifecycle. Cheaper nails may save money initially but can drive up maintenance costs if they corrode or fail prematurely. Conversely, premium nails like galvanized or stainless steel typically cost more, but their durability often reduces the frequency of repairs or replacements, resulting in savings over time.

- Calculate total cost including expected lifetime.

- Consider frequency of inspections or replacements.

- Factor in environmental risks (e.g., coastal corrosion) when choosing material.

When Investing in Premium Nails Pays Off

There are many scenarios where spending more on superior fastener hardware nails is justified: if your project is exposed to harsh environments, requires long-term reliability, or involves high-stakes structural elements. In such cases, the reduced risk of failure, longer lifespan, and lower maintenance can outweigh the higher initial cost. This is especially true for critical infrastructure, outdoor builds, or high-value constructions.

- Long-term construction: decks, bridges, or outdoor pavilions.

- Structures in corrosive environments: marine, chemical plants.

- High safety or load-critical components.

FAQ

What is the difference between common nails and ring-shank fastener hardware nails?

The main difference lies in how they grip the substrate. Common nails have smooth shanks, making them easy to drive but more prone to loosening, especially under stress or vibration. In contrast, ring-shank nails have ridges along their shank that mechanically interlock with wood fibers, offering significantly better holding power and resistance to pull-out. This makes ring-shank nails ideal for applications such as decking, subflooring, or other high-stress assemblies.

Are galvanized fastener hardware nails worth the extra cost?

Yes — galvanized nails are often worth the premium in environments where moisture or humidity is a concern. The zinc coating protects the steel core from rust, which can prevent long-term degradation. For outdoor structures, especially in damp or wet climates, the corrosion resistance can significantly improve the lifespan of the nails and the overall integrity of the construction.

When should I use stainless steel fastener hardware nails? Aren’t they overkill?

Stainless steel nails are particularly beneficial in harsh or corrosive environments — for example, in coastal construction, chemical-exposed areas, or architectural projects where longevity and appearance matter. While they are more expensive upfront, their superior corrosion resistance often justifies the cost for long-term, maintenance-sensitive, or high-value builds.

Can I use standard nails for concrete? Or do I need concrete fastener hardware nails?

Standard nails are generally not suitable for concrete. Concrete is very dense and hard, so you need specialized concrete fastener hardware nails that are hardened and designed to penetrate masonry. Alternatively, masonry fasteners or anchors may be more appropriate depending on load and application. Using the wrong type of nail can result in poor holding or even structural failure.

How do I decide the right nail size (length and diameter) for my project?

Choosing the right nail size depends on the substrate, load, and type of nail. As a rule of thumb, the nail should penetrate at least into the second layer of material to achieve a secure hold. For dense materials or load-bearing joints, you might need a longer and thicker nail. Also, shank design (smooth, ring, or spiral) affects holding strength. If unsure, consult structural guidelines or fastener specification tables.