When it comes to securing furniture components, choosing the right fastener is crucial. Furniture Brad Staples have become a popular choice for many woodworking and upholstery projects due to their versatility, ease of use, and strong holding power. Compared to other fasteners such as nails, screws, or adhesives, brad staples offer a unique combination of convenience and reliability that appeals to both DIY enthusiasts and professional craftsmen.

- Understanding the differences between fasteners can save time and reduce material waste.

- Different fasteners are suited for specific applications, from light upholstery work to heavy-duty woodworking.

- This guide will explore the advantages, limitations, and best use cases for Furniture Brad Staples and compare them to other common fasteners.

Understanding Furniture Brad Staples

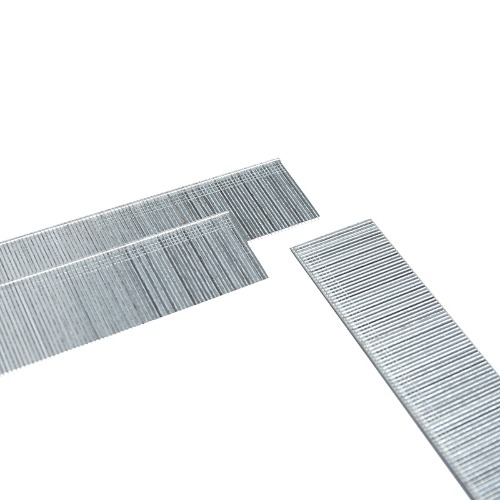

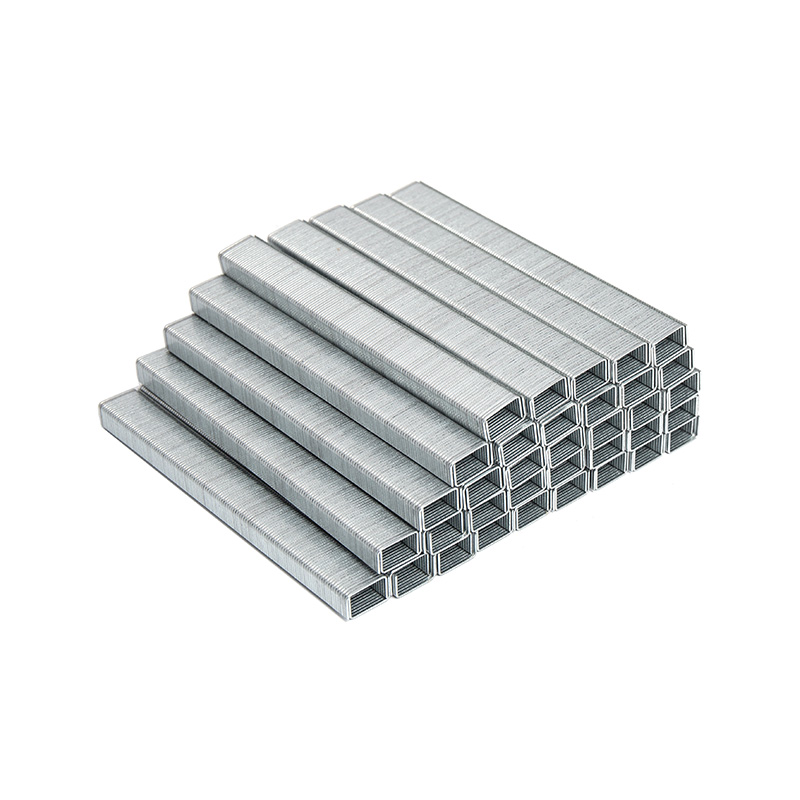

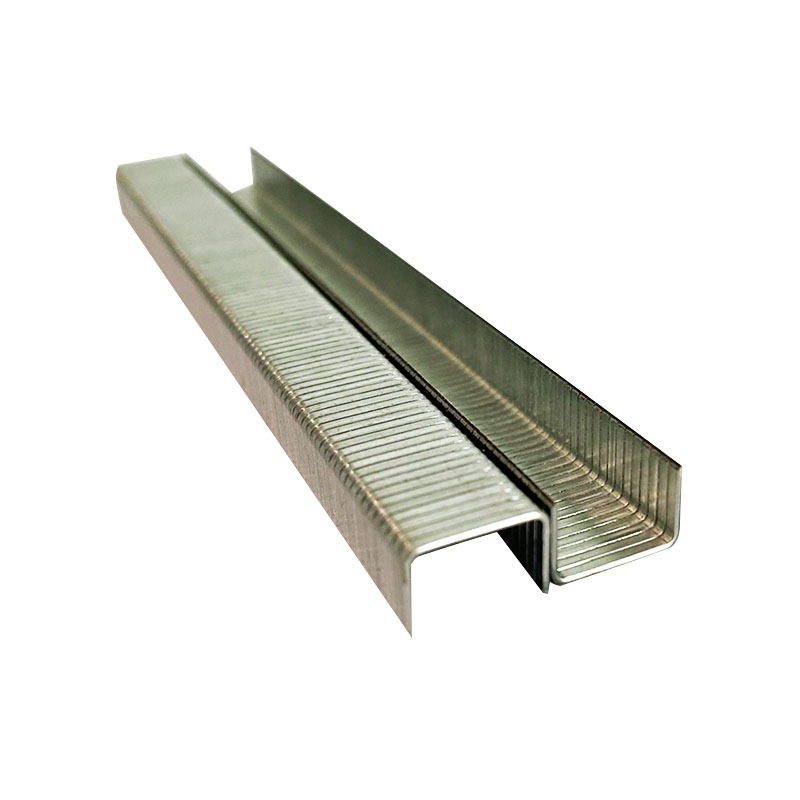

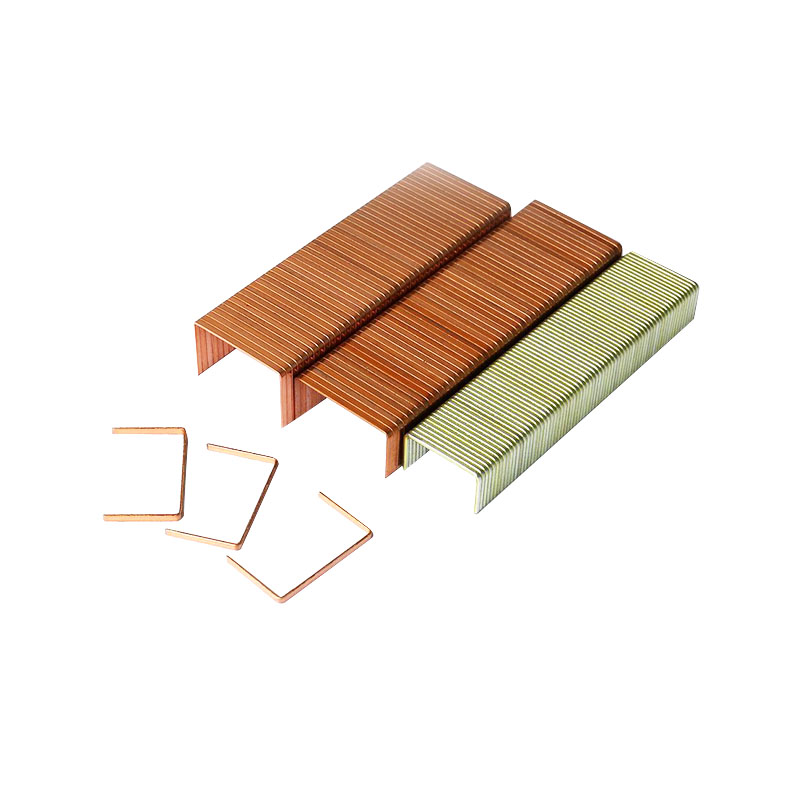

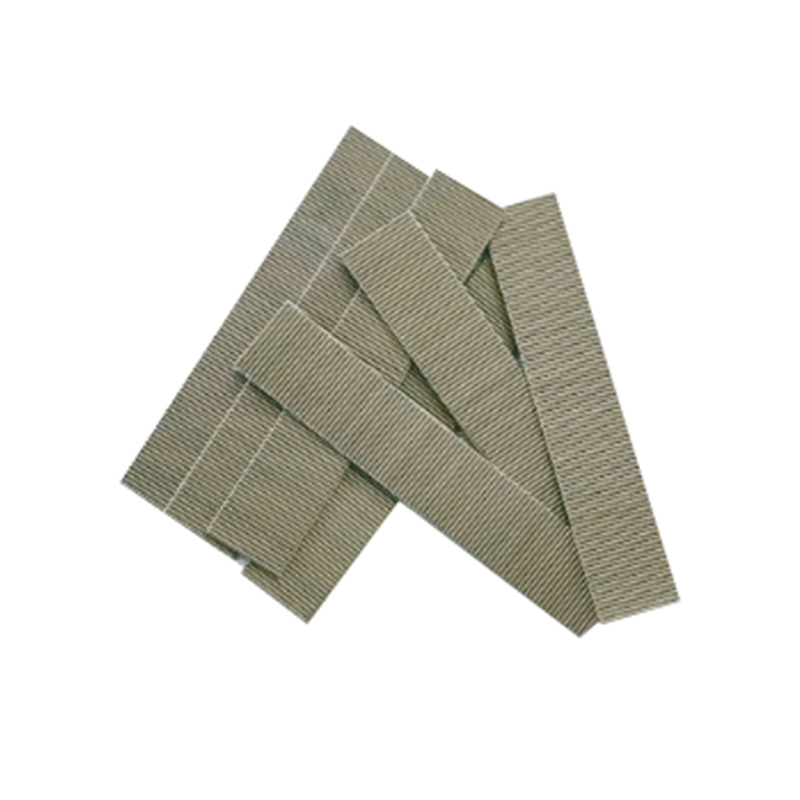

Furniture Brad Staples are small, U-shaped fasteners designed specifically for attaching thin materials like fabric, thin wood, and leather to furniture frames. They provide strong holding power without causing significant damage to delicate surfaces. Over the years, these staples have become indispensable in both commercial and DIY projects, making them a top choice for furniture repair and upholstery.

- Common sizes range from 1/4 inch to 1 inch, suitable for various material thicknesses.

- Brad staples work exceptionally well for DIY Upholstery Projects, providing a secure hold while being easy to insert.

- They are ideal for commercial furniture repairs due to their quick installation and strong adherence.

- Furniture Brad Staples for Woodworking Projects offer precision fastening for crafting custom furniture pieces.

Advantages of Using Brad Staples in Furniture

The benefits of Furniture Brad Staples include efficiency, precision, and minimal surface damage. They can be quickly installed with a staple gun, ensuring a secure hold without splitting wood or tearing fabric. Compared to nails, brad staples are less likely to cause unsightly holes, making them a cleaner choice for visible furniture areas.

- Fast installation for large projects

- Reduced risk of splitting wood or damaging fabric

- Strong hold for lightweight and medium-weight materials

- Cost-effective for both DIY and commercial applications

Comparing Brad Staples with Other Fasteners

When deciding between Furniture Brad Staples and other fasteners such as nails, screws, or adhesives, several factors must be considered. These include material type, holding strength, ease of use, and project requirements. Each fastener has unique advantages and disadvantages depending on the application. By understanding these differences, users can make an informed decision for furniture assembly, repair, or custom projects.

- Brad staples are lightweight and less invasive, ideal for delicate upholstery and thin wood panels.

- Nails provide stronger penetration but can damage thin surfaces.

- Screws offer superior holding power but require pre-drilling and are time-consuming.

- Adhesives provide clean finishes but lack immediate mechanical strength.

Nails vs. Brad Staples

While nails are a traditional fastener for woodworking, they are not always suitable for delicate furniture or upholstery. Furniture Brad Staples provide similar holding power without splitting thin wood or damaging fabric. They are easier to conceal and generally faster to install, making them more efficient for certain projects.

- Brad staples minimize surface damage compared to nails

- They are faster to apply in large-scale projects

- More suitable for lightweight furniture components

| Comparison | Nails | Brad Staples |

| Ease of Use | Medium | High |

| Surface Damage | High | Low |

| Holding Power | Strong | Medium-Strong |

| Best For | Heavy wood | Upholstery, thin wood |

Screws vs. Brad Staples

Screws provide excellent holding power and are ideal for structural joints. However, they require more time and effort for installation. Furniture Brad Staples offer a quicker alternative with sufficient strength for many applications, particularly in upholstery and light woodworking projects.

- Screws are better for heavy structural components

- Brad staples offer efficiency and clean finishes for visible surfaces

- Staples reduce the need for pre-drilling and extra tools

| Comparison | Screws | Brad Staples |

| Installation Time | High | Low |

| Holding Power | Very Strong | Medium-Strong |

| Surface Appearance | Moderate | Clean |

| Ideal Use | Heavy furniture joints | Upholstery, thin wood panels |

Staples vs. Glue and Adhesives

Adhesives can create a clean and smooth finish, but they often lack immediate mechanical strength. Furniture Brad Staples provide instant holding power and allow adjustments before final setting. Combining staples with adhesives can maximize strength and durability.

- Staples provide immediate mechanical support

- Adhesives enhance long-term durability

- Brad staples reduce dependency on drying time and clamping

| Comparison | Glue/Adhesive | Brad Staples |

| Instant Hold | No | Yes |

| Long-Term Strength | High | Medium-High |

| Surface Damage | Low | Low |

| Best Use | Smooth, non-mechanical fastening | Upholstery, thin wood, quick projects |

Choosing the Right Fastener for Your Project

Selecting the appropriate fastener requires understanding the materials, project scope, and intended usage. Factors such as wood type, fabric thickness, and commercial versus DIY applications determine whether Furniture Brad Staples or an alternative fastener is best suited for the job.

- Consider material type: thin wood, fabric, or composite materials

- Project size and complexity influence the choice of fastener

- Durability needs and intended usage dictate mechanical vs. adhesive solutions

- Heavy-duty brad staples are recommended for commercial projects

- Furniture Brad Staples for DIY Upholstery Projects are ideal for home improvement and hobby projects

Best Practices for Using Furniture Brad Staples

Proper technique is essential to maximize the strength and aesthetic appeal of Furniture Brad Staples. Using the right staple size, ensuring correct alignment, and applying consistent pressure will enhance results while minimizing material damage.

- Use a staple gun with adjustable depth control

- Pre-drill or use thin staples for delicate surfaces

- Wear protective equipment and follow safety guidelines

- Combine staples with glue for added strength in heavy-use furniture

FAQ

What are the best sizes of Furniture Brad Staples for upholstery projects?

For DIY Upholstery Projects or commercial applications, sizes typically range from 1/4 inch to 1/2 inch. These staples offer sufficient holding power without damaging fabric or furniture frames. Always consider material thickness and project requirements when selecting staple length and gauge.

Can Brad Staples be used for heavy-duty woodworking projects?

While Furniture Brad Staples for Woodworking Projects provide reliable fastening for light to medium wood, heavy-duty structural components often require screws or nails. For added strength, brad staples can be combined with adhesives to improve durability while maintaining clean surfaces.

Are Furniture Brad Staples better than nails for delicate furniture?

Furniture Brad Staples are preferred for delicate furniture because they minimize splitting and surface damage. Compared to nails, brad staples are easier to conceal and provide a cleaner finish, especially in visible areas like upholstery edges or thin wood panels.

What tools are needed to use Brad Staples efficiently?

To use Furniture Brad Staples effectively, a staple gun or pneumatic stapler is recommended. Adjustable depth controls and proper safety gear ensure consistent results. For commercial or DIY projects, using high-quality staple guns reduces the risk of misalignment and surface damage.

Can Brad Staples be combined with adhesives?

Yes, combining Furniture Brad Staples with adhesives enhances both instant mechanical hold and long-term durability. This approach is common in upholstery and light woodworking projects where additional strength is required without compromising surface appearance.