Selecting the correct fasteners is a fundamental yet often overlooked aspect of successful furniture assembly, repair, and upholstery. Using the wrong type or size can lead to unstable joints, split wood, and a frustratingly unprofessional finish. Brad staples, a hybrid of a small nail and a staple, are indispensable for a wide range of woodworking and fabric-attachment tasks. They are designed to be fired from a pneumatic or electric nail gun, offering speed, consistency, and a minimal footprint that hides easily. This comprehensive guide will delve deep into the world of Brad staples, empowering you with the knowledge to choose the perfect fastener for your project, ensuring strength, durability, and a clean, invisible hold. We'll explore the critical factors of gauge, length, crown size, and material, helping you navigate this essential component of any builder's toolkit.

Understanding Brad Staples: Gauge, Length, and Crown

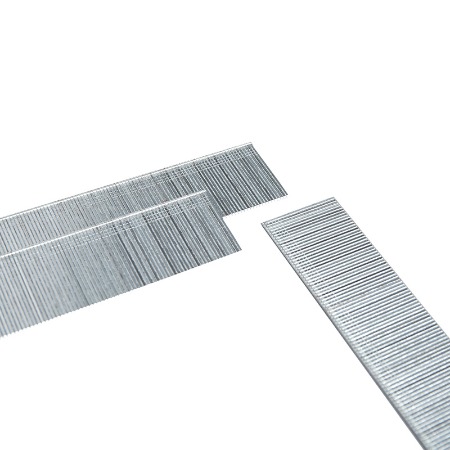

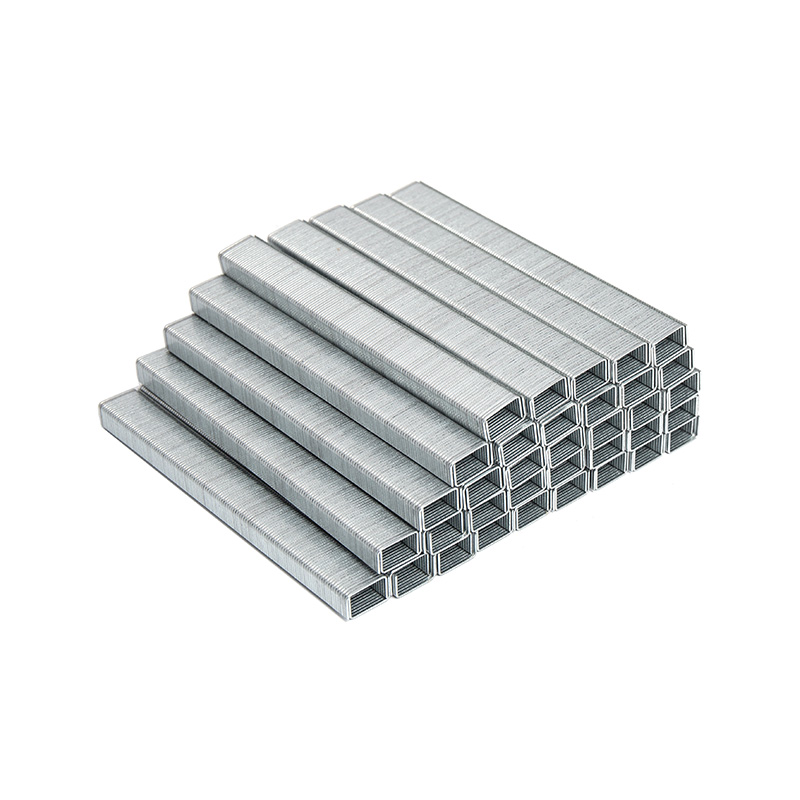

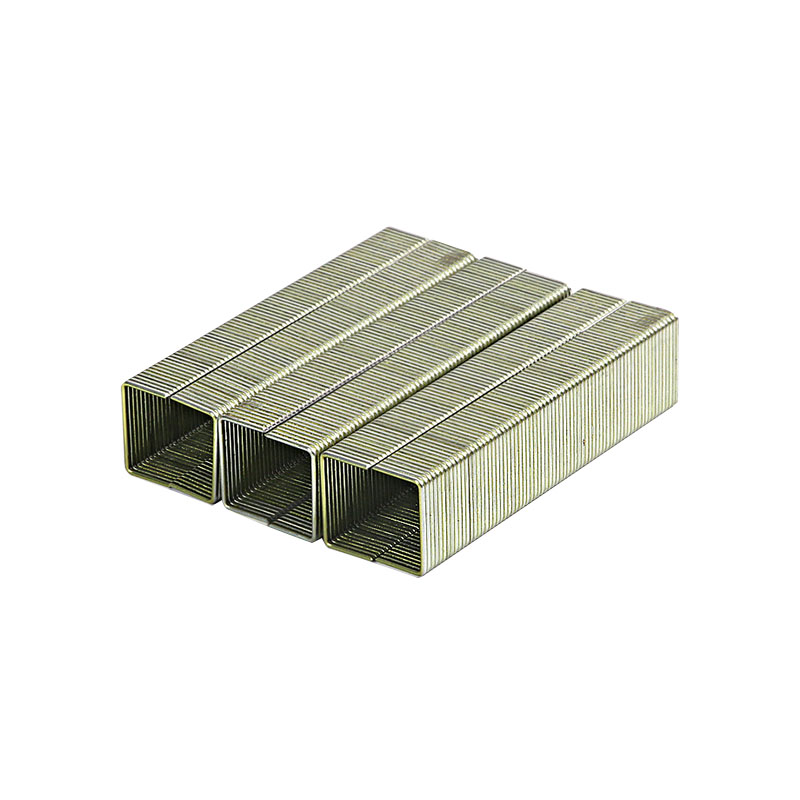

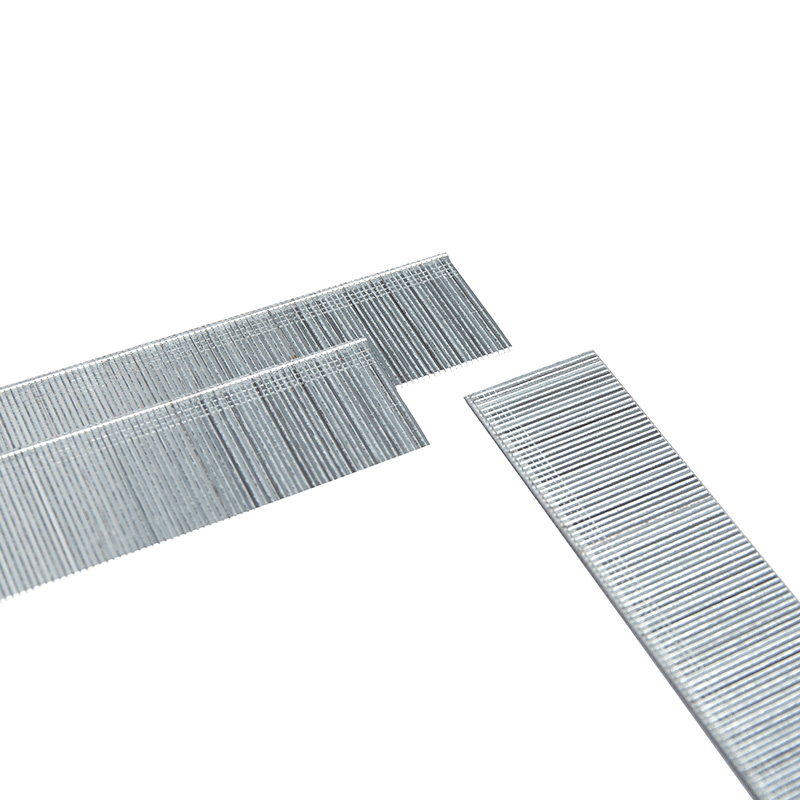

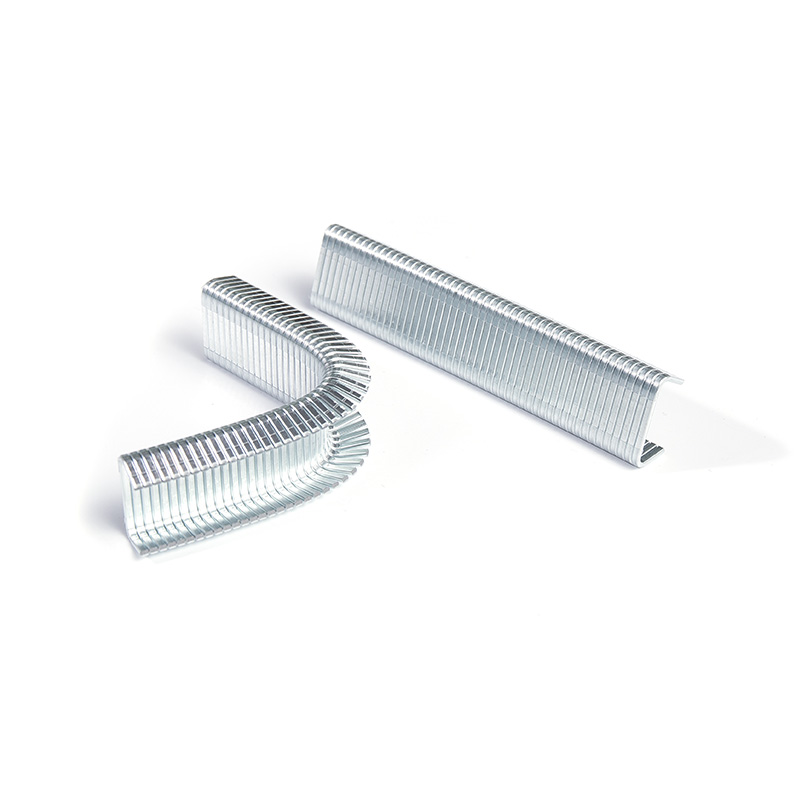

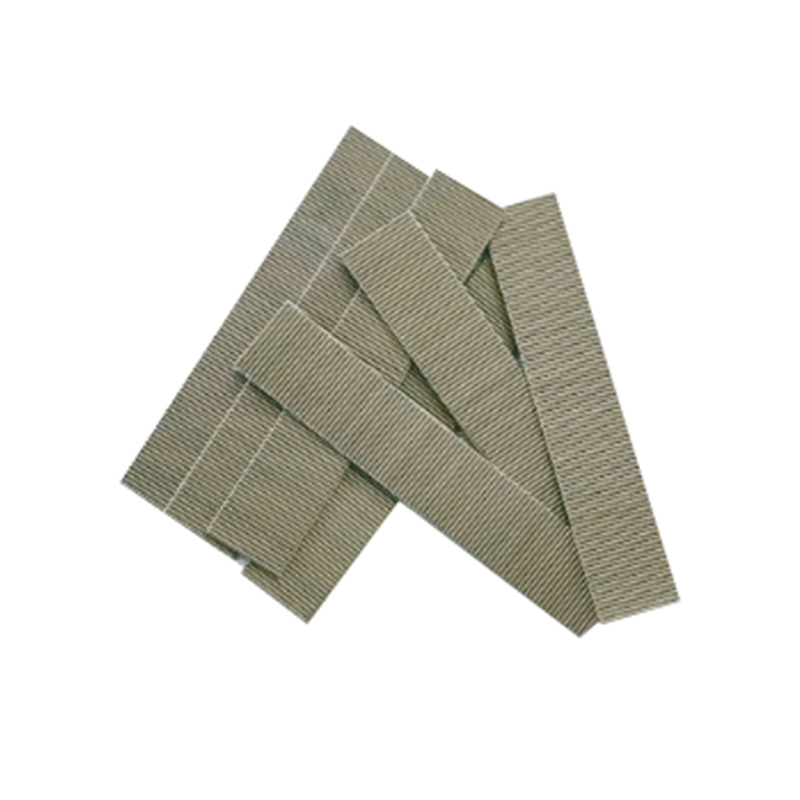

Before diving into specific applications, it's crucial to understand the three primary dimensions that define any Brad staple: gauge, length, and crown width. The gauge refers to the thickness or diameter of the staple's leg. It is counterintuitive, as a smaller gauge number indicates a thicker, stronger staple. Common gauges for furniture work are 18 (fine) and 16 (heavier duty). The length is simply the measurement of the leg, determining how deep the fastener can penetrate into the material. A staple that is too long may blow through the other side, while one that is too short will not provide sufficient holding power. Finally, the crown is the top bridge that connects the two legs. A wider crown provides greater surface area for holding materials like fabric or wire, while a narrow crown is preferred for wood-to-wood joinery as it is less visible and easier to conceal. Mastering the relationship between these three properties is the first step toward selecting the right fastener.

- Gauge (Wire Thickness): Lower numbers mean thicker, stronger wire. 18-gauge is the most versatile for general furniture work.

- Length (Leg Size): Ranges from 1/4 inch for delicate trim to 2 inches for structural joins. Choose a length that penetrates deep into the receiving material without exiting.

- Crown Width: Typically 1/4 inch (narrow) for discrete fastening or 1/2 inch (wide) for securing fabric, batting, or hardware.

How to Choose Brad Nails and Staples for Different Furniture Projects

The ideal Brad staple is not a one-size-fits-all solution; it varies dramatically based on the task at hand. A delicate picture frame assembly demands a completely different fastener than reupholstering a dining chair. For fine woodworking projects like attaching thin trim, assembling small boxes, or securing fragile moldings, a thin 18-gauge brad nail with a narrow crown is perfect. Its small head leaves a nearly invisible hole that is easy to fill. For upholstery projects, such as attaching fabric to a wooden frame or securing batting, a wider crown staple (often 1/2 inch) is essential. This wider crown prevents the fabric from tearing loose under tension and provides a much more secure hold. For heavier-duty applications, like building a bookshelf or attaching cabinet backs, a thicker 16-gauge staple or a finish nail offers the necessary shear strength without the visual bulk of a screw head.

- Delicate Trim & Molding: Use 18-gauge x 1/2" to 1" brad nails. The thin gauge minimizes splitting.

- Upholstery & Fabric: Opt for 18-gauge x 1/2" staples with a 1/2" wide crown for maximum holding power.

- Cabinet & Furniture Assembly: 18-gauge x 1-1/4" brads are excellent for most joints.

- Heavy-Duty Framing: For structural parts, consider moving up to 16-gauge or even 15-gauge finish nails.

Brad Nails vs. Staples: Which One to Use and When?

The choice between a brad nail and a staple often comes down to the required holding power and the material being fastened. Brad nails, being round, offer superior resistance to pull-out forces in solid wood. They are the preferred choice for permanent wood-to-wood bonds where strength is paramount and visibility must be minimized. Staples, with their two legs and a crown, excel in applications where surface area is key. They are unbeatable for securing underlayment, attaching wire, or fastening fabrics and textiles where the goal is to distribute pressure and prevent tearing. For many craftsmen, a combo gun that can shoot both 18-gauge brad nails and 18-gauge staples is the ultimate tool for its versatility, allowing them to switch between fasteners based on the specific step of the project.

| Feature | Brad Nails | Staples |

| Holding Power (Wood) | Excellent resistance to pull-out | Good, but can wiggle loose over time |

| Holding Power (Fabric) | Poor, can tear material | Excellent, distributes pressure |

| Visibility | Very small head, easy to hide | Wider crown, more visible if not hidden |

| Best For | Woodworking, trim, detailed assembly | Upholstery, wire, fabric, underlayment |

Top 5 Tips for Selecting the Best Brad Staples for Woodworking

Achieving professional results in woodworking is heavily dependent on using the right techniques and materials. Your choice of fastener is a critical part of this equation. Firstly, always match the staple length to your material thickness. The goal is for the staple to penetrate deep into the base material without breaking through the surface. A good rule of thumb is to choose a length 2.5 to 3 times the thickness of the piece you are attaching. Secondly, consider the finish of the staple. For interior projects, standard galvanized staples are sufficient. However, for any furniture that might be exposed to moisture, such as outdoor pieces or items in a humid climate, stainless steel staples are a must to prevent unsightly rust stains. Thirdly, always buy name-quality fasteners from a reputable manufacturer; poorly manufactured staples can jam your gun and ruin your workflow.

- Match Length to Material: Ensure the staple penetrates the base wood by at least 3/4 inch for a solid hold.

- Choose the Right Finish: Use stainless steel for outdoor or humid environments to prevent corrosion.

- Quality Matters: Invest in well-made staples to avoid jams, misfires, and inconsistent driving depth.

- Test on Scrap Wood: Always fire a few test staples into a piece of scrap material from your project to check for length, holding power, and splitting.

- Keep Them Organized: Store different sizes and types in clearly labeled containers to avoid mixing them up on the job site.

Where to Buy Brad Staples for Furniture Making: A Beginner's Guide

For those new to the craft, knowing where to source quality fasteners can be daunting. The most accessible options for beginners are large home improvement centers and hardware stores. These stores carry a variety of common sizes and types, allowing you to see the products firsthand. However, for a wider selection of sizes, finishes, and bulk pricing, specialized woodworking stores or online retailers are superior choices. They often stock professional-grade brands that offer better consistency and reliability. When purchasing, pay close attention to the packaging to ensure you are getting the correct gauge, length, and crown size for your nail gun model. It is also highly advisable to buy a small box first to test them in your gun before committing to a large, bulk purchase that might not work well with your specific tool.

- Home Improvement Centers: Best for convenience and small quantities of common sizes.

- Specialized Woodworking Stores: Offer expert advice and a wider range of professional-grade options.

- Online Retailers: Ideal for bulk purchases, hard-to-find sizes, and comparing prices and reviews.

- Always Check Compatibility: Verify that the staple brand and size are recommended for your specific nail gun model to prevent jams.

FAQ

What is the difference between 18-gauge and 16-gauge brad nails?

The core difference lies in the thickness and strength of the fastener. The gauge number refers to the diameter of the wire, and similar to shotgun shells, a lower number indicates a thicker wire. An 18-gauge brad nail is thinner and more delicate, leaving a very small hole that is easy to conceal. It is ideal for fine trim work, delicate moldings, and any application where splitting the wood is a concern. A 16-gauge nail is noticeably thicker and stronger, providing significantly more holding power. It is used for heavier trim, cabinet assembly, and face-frame construction where the additional strength is needed, and the slightly larger hole is acceptable. Choosing between them depends entirely on the structural demands and the visual finish requirements of your project.

Can I use a brad nailer for upholstery projects?

While it is physically possible, it is not recommended. A brad nailer shoots individual round nails, which concentrate all the holding force on a very small point. This makes them prone to pulling through fabric, webbing, or batting, especially under tension. For upholstery, a staple gun that shoots Brad staples with a wide crown is the correct tool. The wide crown (typically 1/2 inch or 3/8 inch) distributes the clamping force over a much larger area, preventing the material from tearing and providing a secure, long-lasting hold. Using the right tool for the job is crucial for achieving a professional and durable result in reupholstery.

How deep should I set my brad staples?

The proper depth is critical for both aesthetics and strength. Brad staples should be set so that the crown is just slightly below the surface of the wood, deep enough to allow for wood filler or putty to be applied smoothly, but not so deep that it compromises the holding power or creates a large crater. Most modern pneumatic nail guns have an adjustable depth dial or wheel. To set it correctly, perform test fires on a piece of scrap wood from your project. Adjust the air pressure or depth setting until the staple is driven to the perfect depth. If you are using a hammer-driven stapler, this requires practice to develop a consistent touch. The goal is a firm hold with a minimal visible impression.

What are the best brad staples for outdoor furniture?

Outdoor furniture is constantly exposed to the elements, making fastener choice critical to prevent failure and staining. For any outdoor project, you must use staples made from a corrosion-resistant material. Standard steel staples will rust quickly, leading to weak joints and unsightly red rust streaks on your furniture. The best choices are stainless steel staples or heavily galvanized staples rated for exterior use. Stainless steel (often 304 or 316 grade) offers the highest level of corrosion resistance and is the premium choice for outdoor furniture that you want to last for many years. Always ensure the staple material is compatible with the wood (e.g., avoid using certain metals with acidic woods like oak without consultation) to prevent galvanic corrosion.

Why do my brad staples keep jamming in my gun?

Staple jams are a common frustration that can usually be traced to a few specific causes. The most frequent culprit is using low-quality or damaged staples. Poorly manufactured staples can have inconsistent sizing, rough edges, or improper coating, causing them to stick together or not feed properly. Another common cause is using staples that are not perfectly compatible with your specific nail gun model. Even slight differences in design between brands can lead to feeding issues. Finally, a lack of proper tool maintenance is a major factor. Dust, debris, and dried oil inside the magazine and drive channel can obstruct the smooth movement of the staple strip. Regular cleaning and light lubrication with a dry-film lubricant designed for nail guns can prevent most jamming issues.