The Rise of Specialized Fasteners in Modern Construction

The construction and contracting landscape is undergoing a significant shift, moving away from a one-size-fits-all approach to fastening solutions. This evolution is driven by increased demands for structural integrity, efficiency on the job site, and long-term durability of projects. At the heart of this transformation are specialized fastener hardware nails, engineered to meet precise challenges. Contractors are increasingly recognizing that the right nail can dramatically reduce labor time, prevent callbacks, and enhance the overall quality of their work. This trend is not about a single product but a comprehensive understanding of material science, application requirements, and performance metrics. The modern contractor prioritizes fasteners that deliver reliability under specific conditions, whether facing extreme weather, working with new composite materials, or needing to meet stringent building codes. This section explores the macro-level factors pushing specialized nails to the forefront of professional toolkits and sets the stage for understanding the specific categories leading the charge.

Superior Holding Power for Demanding Framing Applications

Framing remains the backbone of any structural project, and the choice of nail here is critical. A key trend among contractors is the move towards nails engineered for unparalleled holding power and shear strength. This is particularly evident in the search for and adoption of best nails for pressure treated lumber framing. Pressure-treated lumber, due to its chemical preservatives and often higher moisture content, presents a unique challenge; standard nails can corrode quickly, leading to premature failure and structural weakness.

Understanding the Corrosion Challenge

The chemicals used to protect lumber from rot and insects, such as alkaline copper quaternary (ACQ) or copper azole, are highly corrosive to standard steel. Contractors have learned through costly experience that using the wrong fastener can result in unsightly staining (tannin pull-through) and, more dangerously, significantly reduced structural integrity within just a few years. This has driven demand for fasteners specifically designed to withstand this aggressive environment.

Features of High-Performance Framing Nails

The trending nails in this category share several defining characteristics that differentiate them from basic framing nails:

- Material and Coating: Hot-dipped galvanized (HDG) coatings are a minimum standard, but the trend is towards stainless steel or proprietary double-barrier coatings that offer a thicker, more resilient shield against chemical corrosion.

- Shank Design: Ring shank or screw shank designs have become the norm for critical framing with pressure-treated wood. The threaded shank provides exceptional withdrawal resistance, preventing nails from backing out as the wood dries and seasons, which is a common issue with smooth shank nails.

- Head and Point Design: Full round heads provide a larger bearing surface for securing framing connectors and hangers, while diamond or sharp points allow for easier driving, especially into dense, treated wood, reducing the risk of bending.

Comparison: Standard vs. Engineered Framing Nails

The performance gap between a standard smooth shank, bright finish nail and a modern engineered nail for treated lumber is substantial. For instance, while a standard nail might rely on friction for hold, a ring shank nail acts like a screw, mechanically locking into the wood fibers. The difference in longevity is even more stark; a bright steel nail in contact with ACQ lumber can show significant corrosion in under 6 months, whereas a properly coated nail can last for decades. The following table illustrates key distinctions:

| Feature | Standard Framing Nail (Bright Finish) | Engineered Nail for Treated Lumber |

|---|---|---|

| Primary Material | Basic Carbon Steel | Stainless Steel or HDG-Coated Steel |

| Corrosion Resistance | Very Low; prone to rapid rust and staining | Very High; designed for chemical resistance |

| Withdrawal Resistance | Moderate; relies on friction from smooth shank | Extremely High; ring/screw shank mechanically locks |

| Typical Application | Interior, non-critical framing with dry wood | Exterior framing, decks, posts, all contact with treated wood |

| Long-Term Project Security | High risk of failure, leading to callbacks | High reliability, reducing long-term maintenance |

This focus on specialized performance explains why contractors are trending towards these engineered solutions, viewing them not as an expense but as an investment in project quality and professional reputation.

Enhancing Efficiency and Finish in Exterior Work

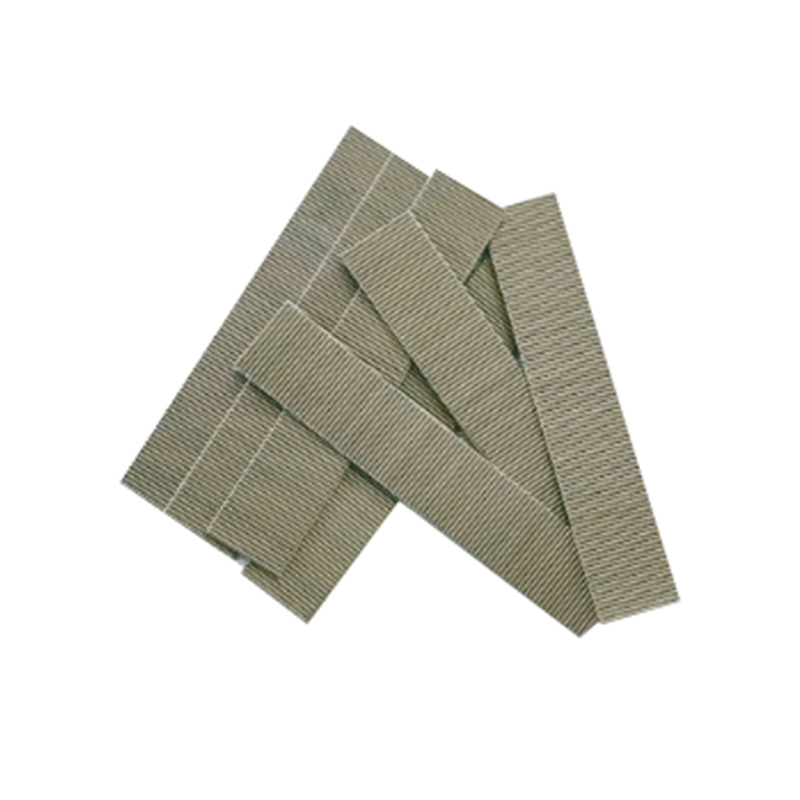

Beyond structural framing, the finish and longevity of exterior siding and trim are paramount for curb appeal and weather protection. Here, the trend is distinctly towards fasteners that disappear while performing a durable function. This is perfectly captured by the growing contractor preference for galvanized ring shank siding nails. These nails solve two major exterior challenges: holding power in the face of seasonal wood movement and resistance to the elements.

The Problem of Siding Failure

Siding failures often stem from nails popping out or corrosion causing streaks. Standard siding nails can work loose as the substrate expands and contracts with humidity and temperature changes. Once a nail backs out, it compromises the seal, allows moisture ingress, and creates an unattractive appearance. Furthermore, rust from a corroding nail can streak down the siding, permanently damaging its finish.

Why Galvanized Ring Shank is the Trending Solution

The combination of galvanization and a ring shank design directly addresses these pain points. The galvanized coating, typically a zinc layer applied through a hot-dip process, acts as a sacrificial barrier. It corrodes slowly over time, protecting the underlying steel from rust. The ring shank design ensures that the nail, once driven, is extremely difficult to pull out. The rings bite into the wood fibers, creating a "one-way" grip that resists the cyclical forces trying to push the nail back out. This is crucial for materials like cedar shingles, hardwood siding, or even engineered wood siding that experience significant movement.

- Improved Workflow: Using these reliable nails reduces the need for re-driving popped nails later in the job or during a final walk-through, saving time.

- Aesthetic Superiority: The small, neat head of a siding nail is designed to be set flush or slightly below the surface without splitting the material. When paired with a color-matched filler, it becomes virtually invisible.

- Long-Term Weathering: A high-quality galvanized coating ensures no rust streaks appear, preserving the clean look of the painted or stained siding for the life of the finish.

Contractors prioritizing quality exterior work have made this nail type a standard in their inventory, recognizing that it safeguards both their installation effort and the client's investment.

The Critical Role of Fasteners in Roofing Integrity

Roofing is arguably one of the most punishing environments for a fastener, subjecting it to UV radiation, extreme temperature swings, wind uplift forces, and moisture. A roof leak can cause catastrophic interior damage, making the choice of fastener a matter of building security. This has led to a clear trend towards highly engineered solutions, particularly the use of rubber washer roofing nails for asphalt shingles.

Anatomy of a Leak-Proof Seal

The primary function of a roofing nail is not just to hold the shingle down, but to create a watertight seal at the point of penetration. A standard nail leaves a hole through which water can wick. The integrated rubber washer (or neoprene gasket) on a roofing nail is designed to compress tightly against the shingle surface, forming a flexible, durable gasket that blocks water entry.

Key Characteristics of Effective Roofing Nails

- Washer Material and Design: The washer must be made of a UV-stable, ozone-resistant elastomer like EPDM rubber. It should be wide enough to create a large seal and thick enough to maintain compression over decades without cracking or degrading.

- Nail Shank and Coating: A ring or spiral shank provides superior wind uplift resistance. The steel must be heavily galvanized or, in coastal areas, made of stainless steel to resist corrosion from constant moisture.

- Driving Consistency: The nail must be driven to the correct depth—flush, not over-driven. An over-driven nail can cut or over-compress the washer, while an under-driven nail leaves the seal incomplete. This makes nail gun precision and adjustment crucial.

Consequences of Using Inferior Fasteners

The risk of using a non-washered nail or one with a poor-quality washer cannot be overstated. Water intrusion at a nail hole is slow and often invisible from the outside, leading to rot in the roof deck, insulation damage, and mold growth in the attic. The cost of repairing this damage far outweighs the minimal premium paid for high-quality, code-compliant roofing nails. Contractors who specialize in roofing understand that their reputation is literally nailed to the roof with each fastener they use, making this category non-negotiable in terms of quality.

Securing Heavy-Duty Connections with Precision

For applications where sheer strength and load-bearing capacity are paramount, such as installing ledger boards for decks, building retaining walls, or securing structural hardware, contractors require a fastener that performs like a bolt but installs like a nail. This need has fueled the popularity of structural screws vs nails for joist hangers. While technically a different fastener class, this debate highlights the trend towards specialized, high-strength fastening.

The Traditional Nail Approach and Its Limitations

Traditionally, joist hangers and other structural connectors were fastened with short, thick nails, often specified by the connector manufacturer. While effective when driven perfectly, this method has drawbacks. Hand-driving numerous nails in tight spaces is time-consuming and physically demanding. There's also a risk of missing the mark or bending a nail, which can compromise the connection's strength. Furthermore, if a nail needs to be removed for an adjustment, it is extremely difficult without damaging the surrounding wood.

The Rise of the Structural Screw

Structural screws, also known as ledger screws or heavy-duty screws, are engineered to be direct replacements for these specified nails. They are made from hardened steel and have aggressive threads and sharp points designed for fast driving with an impact driver.

| Aspect | Traditional Joist Hanger Nails | Modern Structural Screws |

|---|---|---|

| Installation Speed | Slower; requires multiple hammer strikes per nail | Faster; driven quickly with an impact driver |

| Installation Control | Higher risk of bending or glancing blows | Precise, straight installation with less user fatigue |

| Adjustability & Removal | Very difficult to remove without damage | Can be backed out and re-driven if needed |

| Shear and Tensile Strength | Strength is certified when used as specified | Strength is certified and often comparable or superior; must be verified for the specific connector. |

| Tool Requirement | Hammer or pneumatic nailer | Impact driver or high-torque drill |

It is critical to note that contractors must always use fasteners that are officially approved and listed for use with the specific connector brand and model. The trend, however, is clear: where code and manufacturer specifications allow, professionals are opting for the speed, precision, and reduced installer error offered by structural screws for these critical points. This shift underscores the broader theme of using purpose-engineered fasteners to achieve better results more efficiently.

Choosing the Right Fastener for Composite and Engineered Materials

The building materials revolution has introduced a wide array of composite decking, trim boards, and structural elements. These materials, often made from wood fiber and plastics or entirely synthetic composites, have different fastening requirements than natural wood. A common and critical question for contractors is how to choose between stainless steel and coated nails for composite decking. Making the wrong choice here can lead to staining, "mushrooming" around the fastener head, and premature failure.

Understanding Material Interaction

Composite materials can be abrasive and may contain chemicals or moisture that reacts with certain metals. Furthermore, they expand and contract at different rates than traditional lumber. A fastener must accommodate this movement without loosening or causing cosmetic damage.

Stainless Steel: The Premium Choice

Stainless steel nails, particularly 304 or the more marine-grade 316 series, offer the highest level of corrosion resistance. They are essentially inert and will not react with any chemicals in the composite material. This makes them the safest choice to prevent any chance of rust staining, which is a critical concern with light-colored or capped composite decking. Their strength and durability are exceptional, though they come at a higher upfront cost.

- Best For: High-end composite decking projects, coastal environments with salt spray, areas with extreme weather, or when the manufacturer's warranty explicitly recommends or requires stainless steel.

- Consideration: The initial investment is higher, but it eliminates the risk of costly warranty claims or deck replacement due to fastener failure.

High-Quality Coated Nails: The Engineered Alternative

Some manufacturers produce specially engineered coated nails designed for composites. These may have a thick polymer coating or a proprietary metallic coating that provides a barrier. They are often color-matched to the decking (e.g., gray or brown) for a more hidden appearance.

- Best For: Projects where budget is a greater constraint and the composite manufacturer approves a specific coated fastener. They may also be preferred for their color-matching ability.

- Consideration: It is imperative to verify that the coated nail is explicitly rated and warrantied for use with the specific brand of composite material. The coating must be tough enough to resist scraping off during the driving process.

The trend among informed contractors is to lean heavily towards stainless steel for critical composite applications, viewing the extra cost as insurance for their labor and the client's satisfaction. This meticulous approach to matching the fastener to the substrate exemplifies the professional diligence that is now standard in the industry, ensuring that modern materials perform as intended for their full lifespan.