Understanding the Role of Heavy Wire Staples in Modern Applications

What Defines Heavy Wire Staples

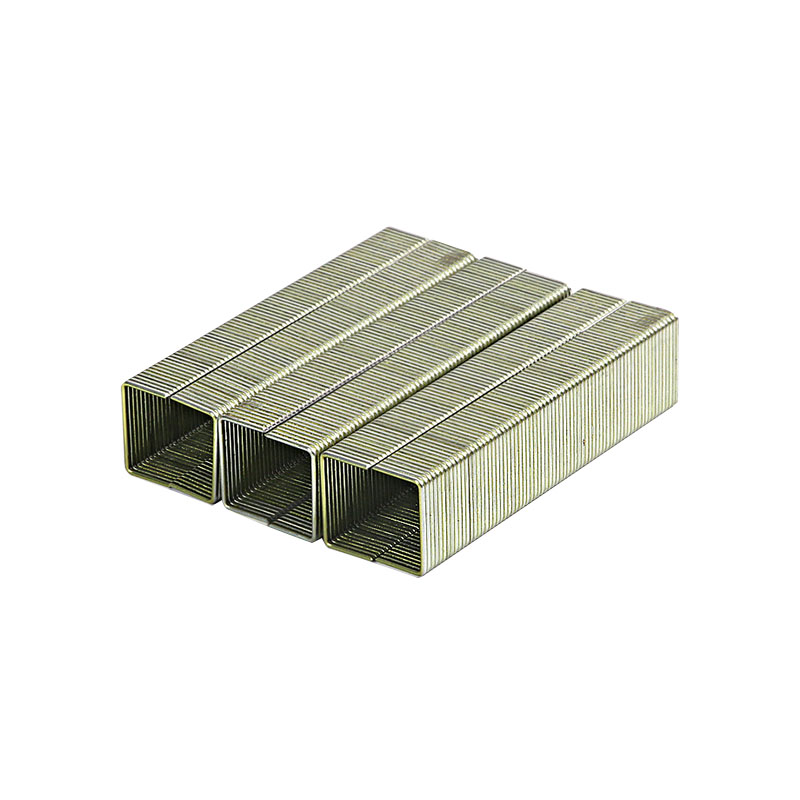

Heavy Wire Staples are widely used across industrial, construction, and woodworking sectors due to their remarkable strength and adaptability. These staples are designed with thicker wire diameters, enabling them to withstand higher tension, heavier loads, and more aggressive working environments than standard staples. In many modern applications, professionals require fastening components capable of maintaining structural integrity over long periods, even when exposed to pressure, vibration, or outdoor elements. As a result, heavy wire staples have become the preferred fastener for industries seeking secure, durable, and efficient fastening solutions. Their versatility also allows them to be compatible with multiple materials including hardwoods, engineered lumber, insulation layers, and composite panels.

- Thicker wire diameter ensures superior holding power

- Widely used in both heavy-duty and precision applications

- Adaptable to various surfaces including wood, composites, and insulation

Key Advantages Compared with Other Fasteners

When compared with screws, nails, or lighter-grade staples, Heavy Wire Staples deliver unique advantages that elevate them as an essential component in industrial workflows. Their ability to distribute pressure evenly minimizes material splitting, making them ideal for delicate yet demanding applications. Additionally, the fastening process is significantly faster, allowing workers to complete large-scale tasks with enhanced productivity. The durability provided by the thicker gauge wire allows the staples to resist deformation during installation and support long-term structural reliability. Industries that prioritize efficiency, cost-effectiveness, and consistent performance frequently select heavy wire staples for these reasons.

- Offers faster installation compared to screws and nails

- Reduces risk of surface damage or splitting

- Provides long-term stability due to stronger wire composition

| Feature | Heavy Wire Staples | Traditional Staples |

| Strength | High | Medium/Low |

| Durability | Excellent | Limited |

| Best Use Cases | Industry, Construction, Woodworking | Light-duty tasks |

Why Heavy Wire Staples Excel in Industrial and Construction Fields

Performance of industrial grade heavy wire staples

Industrial grade heavy wire staples deliver exceptional durability and performance, making them stand out in environments that demand consistent fastening power. These staples are engineered to withstand repetitive mechanical stress, impact, and continuous vibration from high-powered tools. Industries such as manufacturing, packaging, and assembly rely on these staples not only for their strength but also for their reliability across thousands of fastening cycles. Their superior retention capability ensures high holding strength, preventing loosening over time and reducing maintenance requirements. The combination of rugged material construction and precise manufacturing standards ensures that industrial-grade staples deliver unparalleled consistency for long-term use.

- Engineered for maximum resistance against wear and tear

- Delivers uniform performance in fast-paced industrial settings

- Reduced risk of loosening after repetitive mechanical impact

Benefits of heavy duty wire staples for construction

Construction environments require fasteners capable of withstanding demanding conditions, and heavy duty wire staples for construction provide the strength necessary to secure structural materials effectively. These staples are specifically designed to penetrate dense wood, engineered timber, and layered construction substrates without bending or breaking. Their thick wire composition enhances their ability to support heavy loads, making them indispensable for tasks such as framing, insulation installation, roofing underlay attachment, and subfloor reinforcement. Professionals choose heavy-duty staples for their speed of installation and improved efficiency, as they help reduce labor time while maintaining a high level of fastening precision.

- Designed for high-strength penetration of dense building materials

- Reliable for tasks like roofing, framing, and insulation work

- Helps improve efficiency in large-scale construction projects

| Construction Task | Recommended Fastener | Reason |

| Framing | Heavy Wire Staples | Superior grip and strength |

| Roofing | Heavy Wire Staples | Excellent wind and moisture resistance |

| Subflooring | Heavy Duty Staples | Prevents material shifting |

Material Strength and Durability Features

corrosion resistant heavy wire staples in Harsh Environments

Harsh and moisture-prone environments require fastening components with exceptional durability, and corrosion resistant heavy wire staples meet these demands with efficiency. These staples are engineered using treated or coated wire materials that protect against rust, oxidation, and chemical exposure. Their performance remains consistent even when used outdoors, in coastal conditions, or in industrial spaces that experience fluctuating humidity levels. Corrosion resistance extends the lifespan of the fastening system, reducing the need for replacement or maintenance while ensuring that materials remain firmly secured. Professionals in construction, landscaping, marine environments, and outdoor product assembly often rely on corrosion-resistant staples for their long-term reliability.

- Ideal for outdoor, marine, and moisture-heavy environments

- Protective coating prevents rust and chemical degradation

- Reduces long-term maintenance and replacement costs

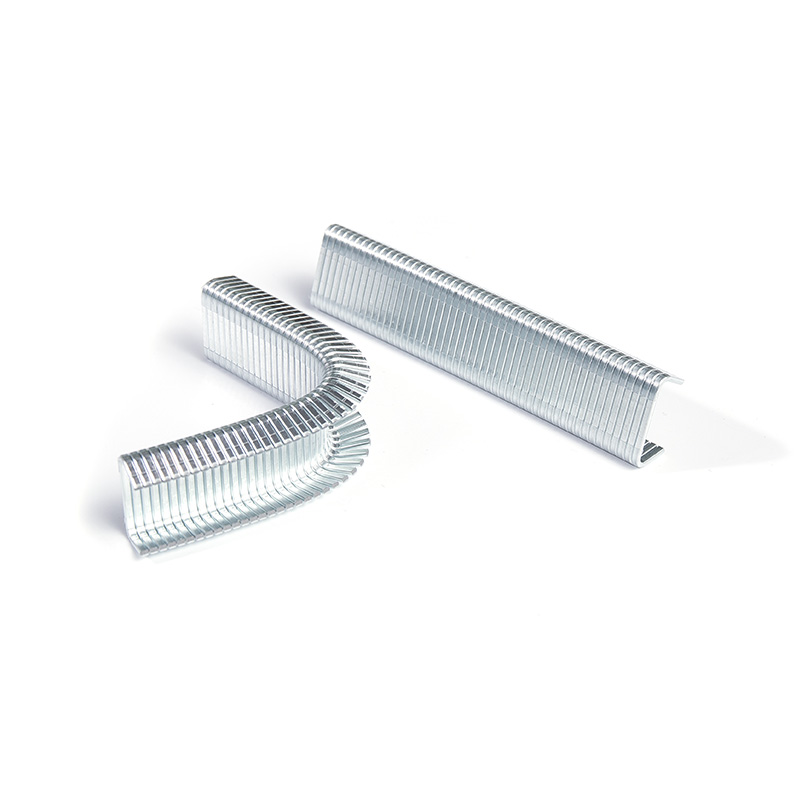

high tensile strength wire staples and Load Performance

When heavy loads or high mechanical stress are involved, high tensile strength wire staples provide unmatched fastening stability. These staples are produced using steel wire with enhanced tensile ratings, enabling them to resist stretching, pulling, and shearing forces. Their performance is essential in applications where structural integrity is critical, such as packaging heavy crates, securing thick lumber materials, or assembling industrial equipment. By incorporating high tensile staples, users ensure that the fastening points remain firm, even when subjected to vibrations, torque, or external impact. This level of strength makes them a top choice for professionals seeking both safety and reliability.

- High resistance against stretching and shearing

- Perfect for heavy-load applications

- Ensures secure fastening in vibration-prone environments

| Feature | High Tensile Staples | Standard Staples |

| Tensile Strength | Very High | Moderate |

| Best Use | Industrial & Heavy Load | General Use |

| Long-Term Reliability | Excellent | Limited |

Heavy Wire Staples in Woodworking and Precision Tasks

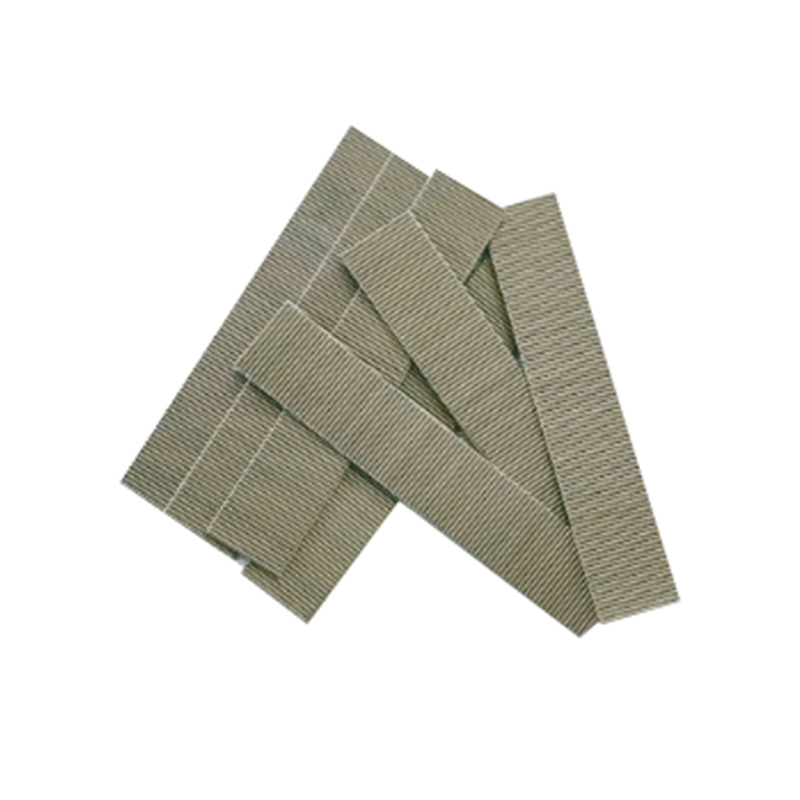

Applications of heavy wire staples for woodworking

In woodworking, precision and stability are essential, and heavy wire staples for woodworking offer the reliable fastening performance required for both decorative and structural wood applications. These staples provide controlled penetration, preventing unnecessary splitting or damaging of delicate wood grains. Whether used in cabinetry, furniture framing, interior trim work, or plywood reinforcement, their holding power ensures materials stay securely in place. Woodworkers value heavy wire staples for their speed, efficiency, and compatibility with various grades of natural and engineered wood. The combination of precise entry and strong grip supports cleaner craftsmanship and improved assembly efficiency.

- Reduces risk of cracking or splitting fine wood surfaces

- Ideal for furniture, cabinetry, and interior trim work

- Offers consistent penetration for precise fastening

How They Improve Accuracy and Holding Strength

Accuracy is vital in both industrial and artisan woodworking, and Heavy Wire Staples significantly enhance the precision of fastening tasks. Their rigid structure ensures straight penetration, minimizing deviation and reducing installation errors. Because they provide a high level of clamping force, they maintain consistent pressure across the contact area, enhancing the bonding of joints and structural components. This level of performance ensures the final product remains sturdy and well-aligned even under load or movement. For tasks requiring detailed craftsmanship, these staples offer both the control and reliability needed to achieve professional results.

- Ensures precise fastening across various materials

- Delivers consistent clamping force for long-term alignment

- Supports both large-scale and fine-detail woodworking tasks

| Woodworking Task | Heavy Wire Staples | Other Fasteners |

| Cabinetry | Excellent Grip | Moderate |

| Trim Work | Precise and Clean | Risk of Over-penetration |

| Plywood Assembly | High Stability | Varies |

How to Choose the Best Heavy Wire Staples for Your Needs

Factors to Prioritize

Selecting the right type of Heavy Wire Staples depends on understanding material requirements, environmental conditions, and load expectations. Users should prioritize staple wire gauge, coating treatment, corrosion resistance, tensile strength, and compatibility with intended materials. Assessing these factors ensures the chosen staple will deliver maximum performance and durability. Whether the staples are intended for industrial machines, construction frameworks, or woodworking tables, choosing the correct specification can significantly improve both efficiency and structural reliability. In addition, evaluating environmental conditions—such as exposure to moisture, chemicals, or outdoor weather—is essential for achieving long-term fastening success.

- Check wire gauge and length to match material density

- Consider corrosion resistance for outdoor applications

- Select high tensile staples for heavy-load requirements

Comparison Table of Specifications

A proper comparison helps users identify the best-performing Heavy Wire Staples for their specific tasks. By evaluating factors such as strength, corrosion resistance, and application scenarios, professionals can make smart and cost-effective decisions. The table below provides a clear overview of how different performance attributes vary among staple types, offering guidance toward selecting the optimal fastener for each project. Considering these specifications ensures users align staple properties with job requirements, maximizing durability and fastening efficiency.

| Staple Type | Strength | Corrosion Resistance | Best Application |

| Industrial Grade | Very High | Moderate | Factories & Manufacturing |

| Heavy Duty Construction | High | High | Construction & Assembly |

| Corrosion Resistant | High | Very High | Outdoor & Marine |

| High Tensile Strength | Excellent | Moderate | Heavy Load Projects |

FAQ

Are Heavy Wire Staples Suitable for Outdoor Construction?

Yes. Heavy Wire Staples—especially corrosion-resistant types—are ideal for outdoor projects due to their ability to withstand moisture, temperature changes, and long-term exposure. They offer excellent holding power for roofing, fencing, framing, and exterior woodwork.

What Is the Difference Between Industrial Grade and Heavy Duty Wire Staples?

Industrial grade heavy wire staples are optimized for continuous, high-volume use in manufacturing environments, while heavy duty wire staples for construction are built to handle high penetration strength and structural loads. Both offer superior durability but serve different applications.

Why Choose High Tensile Strength Wire Staples?

High tensile strength wire staples provide unmatched resistance to pulling, bending, and shearing, making them ideal for heavy-load materials, vibration-prone machinery, and industrial assembly tasks. They ensure secure fastening under extreme conditions.

Can Heavy Wire Staples Be Used for Fine Woodworking?

Yes. heavy wire staples for woodworking offer precise penetration with minimal risk of wood splitting. Their controlled fastening makes them ideal for cabinetry, furniture work, trim installation, and interior finishing.

Are Corrosion Resistant Heavy Wire Staples Worth It?

Absolutely. corrosion resistant heavy wire staples significantly extend the life of fastening systems in environments exposed to moisture, chemicals, or outdoor weather. They reduce maintenance needs and ensure long-term fastening stability.