1.Building Under Pressure: The Corrosion Challenge in Modern Construction

1.1 Environmental Exposure Demands Material Integrity

Modern buildings are increasingly exposed to aggressive natural elements — humidity, precipitation, temperature fluctuations, and airborne salinity all accelerate material degradation. Metal fasteners, in particular, face constant threats from oxidation and corrosion, jeopardizing the structural integrity of entire systems.

1.2 Corrosion: A Silent Threat to Structural Safety

When corrosion sets in, the affected metal loses its strength, ductility, and ability to perform under load. This can result in the loosening of joints, compromise of anchoring systems, and, in severe cases, structural failures. The early signs are often invisible, making prevention far more cost-effective than repair.

1.3 The Industry’s Urgent Need for Durable Fasteners

As buildings are increasingly designed for longer service lives and built in harsher environments, the demand for robust, corrosion-resistant fasteners has become a top priority in construction material selection. Steel Row Nails emerge as a reliable solution to this pressing industry need.

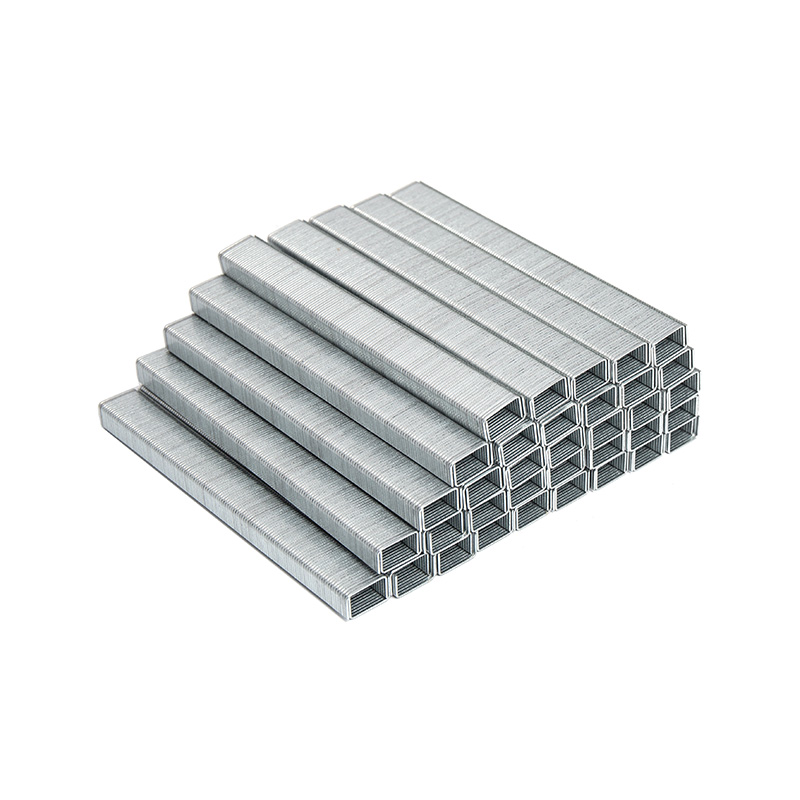

2.Steel Row Nails: Defending Structures with Advanced Corrosion Resistance

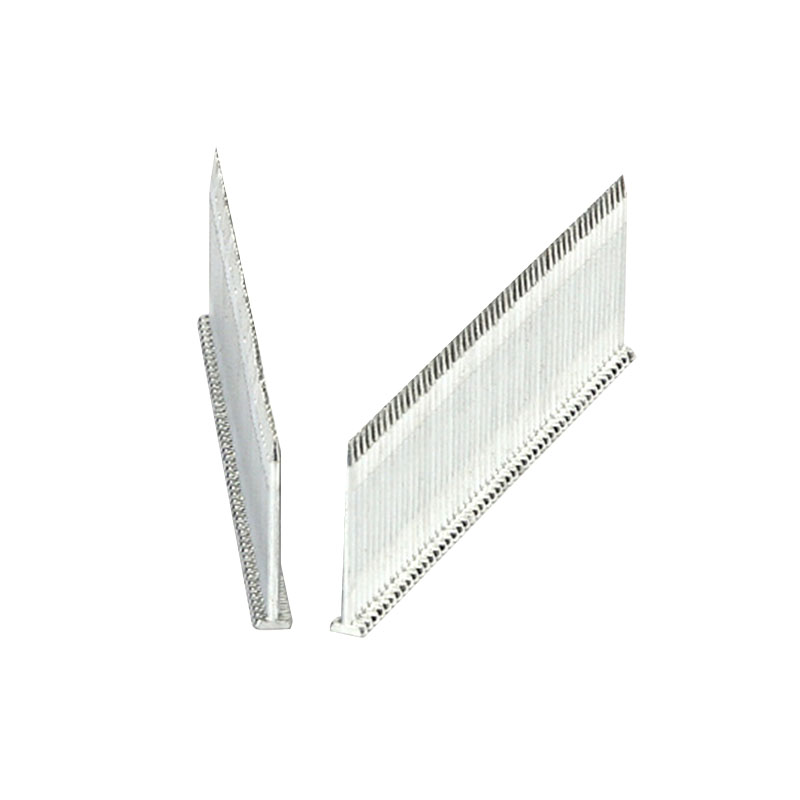

2.1 Engineered for Harsh Environments

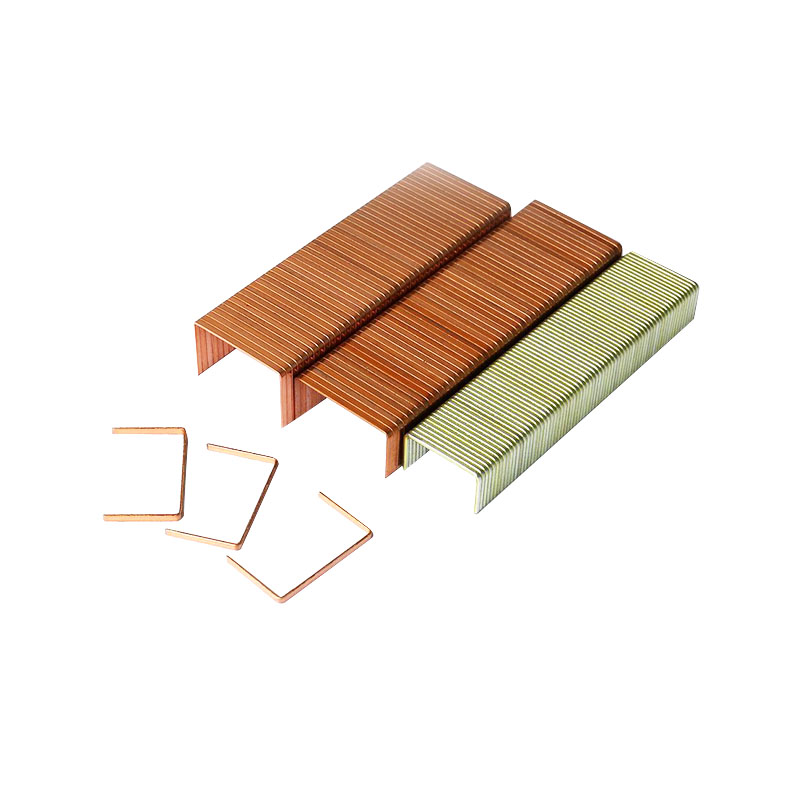

Steel Row Nails are manufactured from premium-grade steel and enhanced with advanced anti-corrosion coatings, allowing them to perform reliably in moisture-rich, salt-laden, or high-temperature environments. These nails resist degradation, maintaining full mechanical integrity where conventional nails fail.

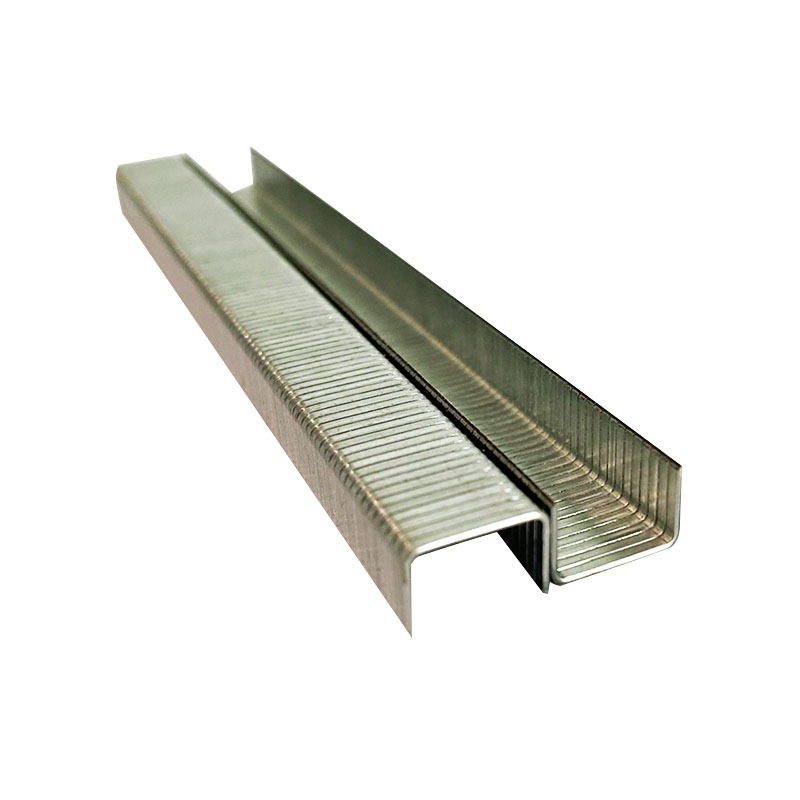

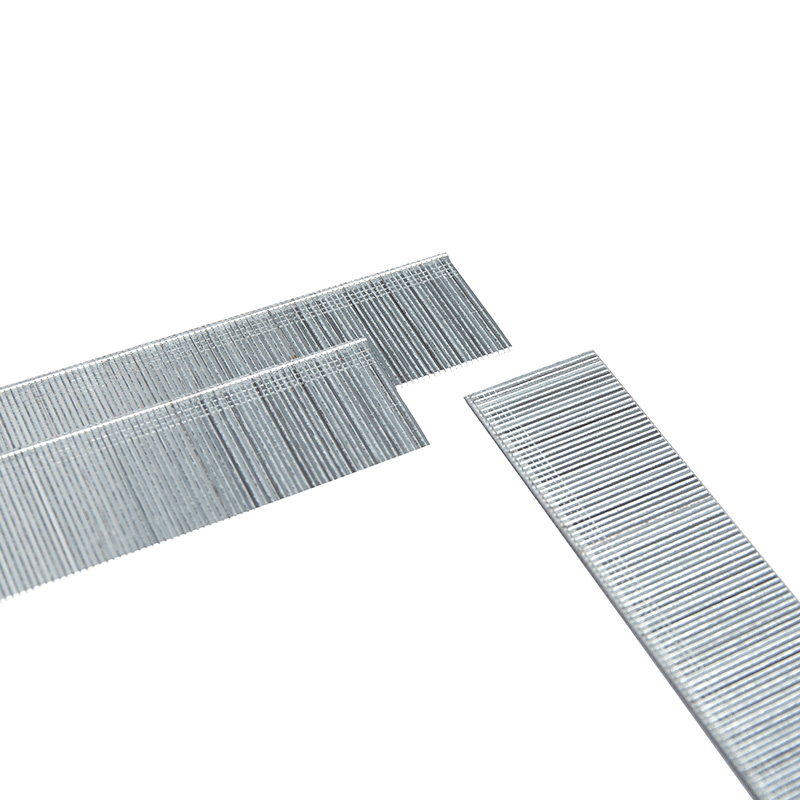

2.2 Surface Technology as a Shield Against Oxidation

One of the key differentiators lies in the specialized surface treatment process. This protective coating acts as a barrier against corrosive agents like water and oxygen, significantly improving oxidation resistance. Even in prolonged outdoor or semi-submerged applications, the treated surface resists rust, ensuring long-term performance.

2.3 Consistent Performance in All Climates

From tropical humidity to coastal salt exposure and arid desert winds, Steel Row Nails deliver uniform performance across various climate zones. Their resistance to material fatigue and corrosion allows builders to depend on them in both standard and extreme conditions, reducing the risk of premature failure or performance degradation.

3.Built to Last: Economic, Structural, and Environmental Benefits

3.1 Lower Long-Term Maintenance, Higher ROI

Using corrosion-resistant Steel Row Nails minimizes the frequency of replacements and structural inspections caused by fastener failure. This translates directly to reduced labor costs and lower material expenditures over a building’s lifecycle, providing developers and facility managers with measurable cost savings.

3.2 Reinforcing Safety and Stability in Every Joint

In mission-critical structures — from high-rise buildings to infrastructure projects — maintaining the tightness and stability of connections is paramount. Steel Row Nails preserve their clamping force even after years of exposure, preventing loosening and contributing to safer, more resilient buildings.

3.3 Supporting Green Construction Through Longevity

Durable materials are not only practical but also environmentally responsible. By extending the service life of building components and reducing waste from replacements, Steel Row Nails support sustainable building practices. Their performance under corrosive stress helps construction teams meet both durability standards and environmental targets.