1.Outdated Fastening: The Hidden Weaknesses of Traditional Nails

1.1 Structural Instability from Conventional Design

Traditional nails rely on visible nail heads to achieve anchoring, but this exposed design introduces points of weakness. Over time, the bond between the nail head and shaft may loosen under repeated stress or environmental pressure, leading to instability in the overall structure.

1.2 Damage During Installation and Use

Driving traditional nails into delicate surfaces like wood or drywall often results in surface cracking, splitting, or indentation. The nail head disrupts the material continuity, which not only affects the appearance of the finished surface but also weakens its load-bearing capability.

1.3 Vulnerability to Environmental Stressors

Conventional nails are highly susceptible to oxidation and corrosion due to exposure to moisture, air, and temperature fluctuations. This compromises their long-term holding power, especially in high-humidity or variable-temperature environments such as kitchens, bathrooms, or coastal regions.

2.The Evolution of Fastening: Headless Nails Redefine Structural Reliability

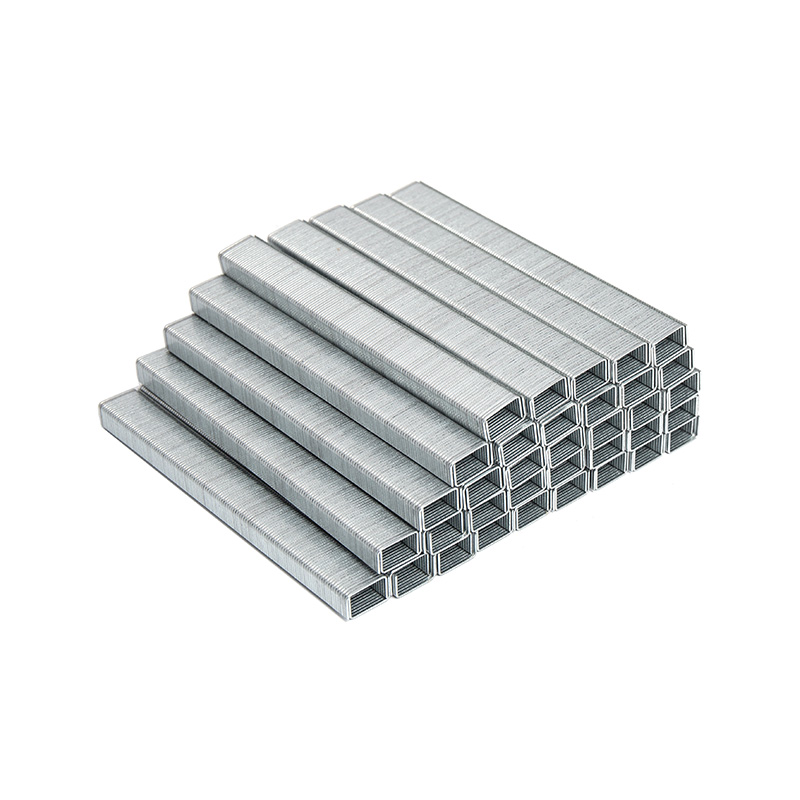

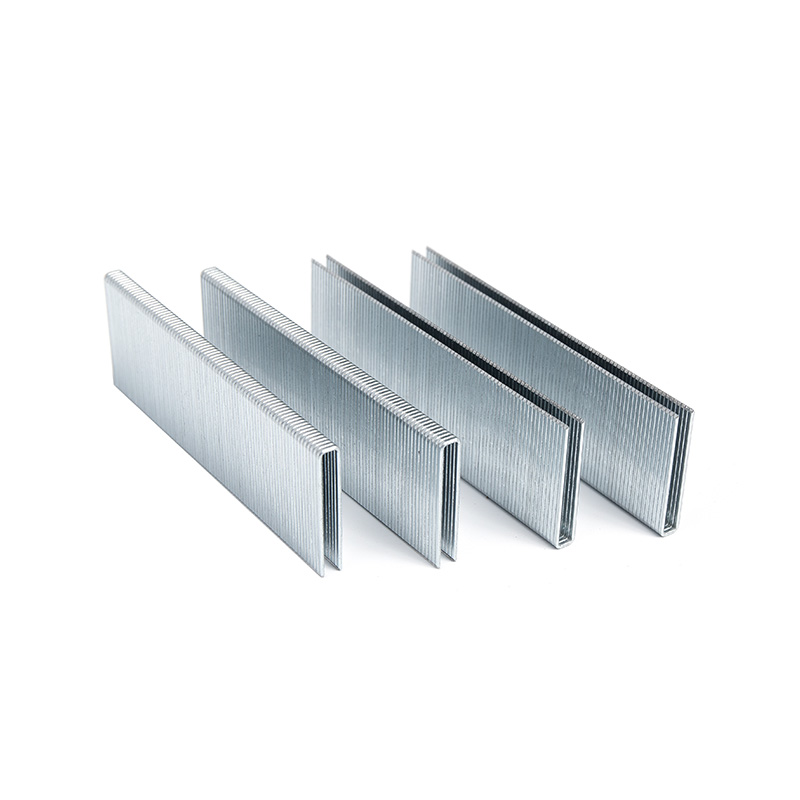

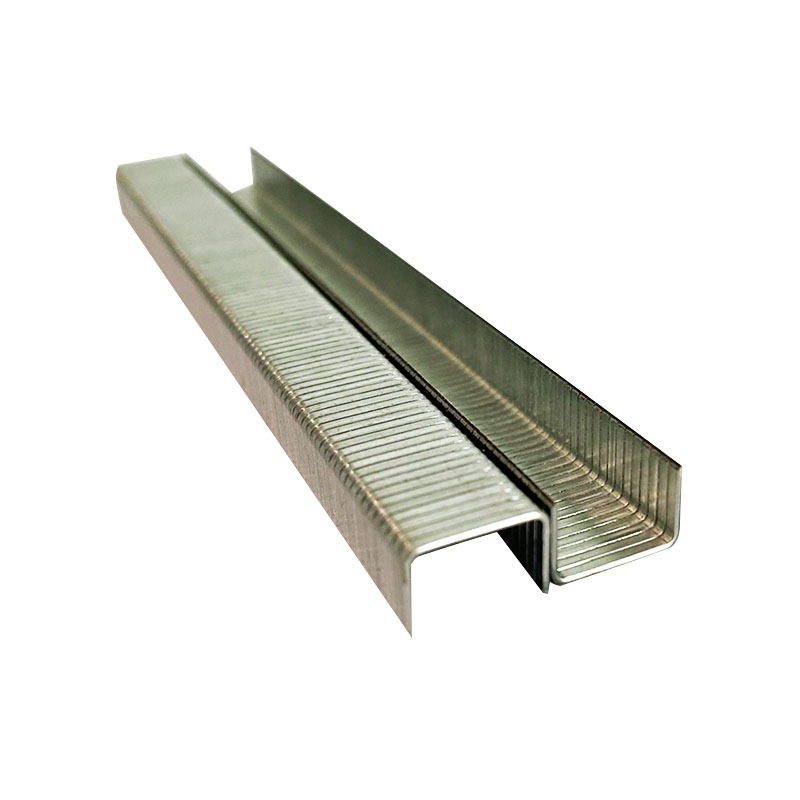

2.1 Streamlined Design Enhances Embedding and Grip

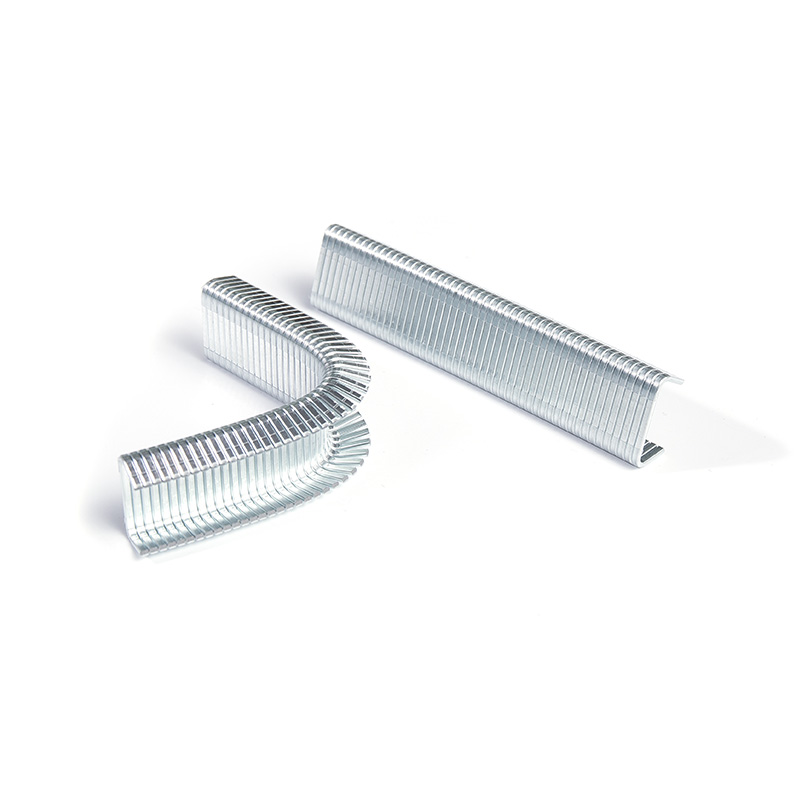

Unlike traditional nails, headless nails feature a minimal, streamlined shape that allows them to sink seamlessly into the material without causing surface disruption. This design increases material contact and friction, resulting in a significantly stronger and more durable hold.

2.2 Increased Friction for Enhanced Retention

The shaft of a headless nail is often finely engineered with micro-ridges or grooves, maximizing surface area contact within materials like wood or fiberboard. This ensures that once inserted, the nail resists both withdrawal and lateral movement, even under continuous mechanical stress.

2.3 Superior Load-Bearing in Decorative Applications

Headless nails are especially effective in decoration and trim installations, where precision and holding strength are critical. Their firm grip prevents long-term loosening even under vibration, weight, or repeated movement, making them ideal for moldings, panels, and built-in cabinetry.

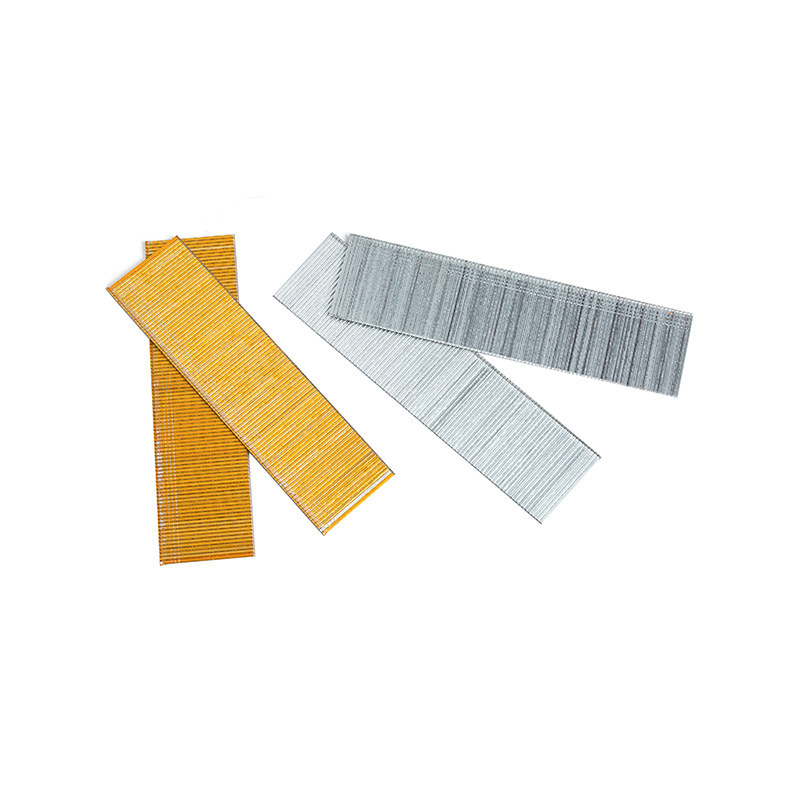

3.Long-Term Gains: Headless Nails Reduce Risk and Raise Efficiency

3.1 Durability Under Environmental Duress

Constructed from corrosion-resistant materials, headless nails are built to endure exposure to moisture, temperature extremes, and air pollutants. They maintain structural performance without rusting, ensuring long-term strength in both interior and semi-exterior applications.

3.2 Reduced Maintenance and Repair Intervals

Thanks to their secure fixing and robust resistance to loosening, headless nails significantly reduce the need for future repair or replacement. This directly translates to lower lifecycle costs, less downtime for property owners, and fewer interruptions for occupants.

3.3 Material Optimization and Faster Project Delivery

The reliability of headless nails minimizes waste caused by failed installations or replacements. Their consistent performance reduces the need for adjustments, helping craftsmen finish work faster with fewer errors. This efficiency streamlines workflows and optimizes overall project resource use.