1.Revolutionizing On-Site Construction: Fastener Hardware Nails Streamline Installation

1.1 Eliminating Complexity from Traditional Fastening

Traditional fastener installation involves multiple steps, tools, and operator skills, making the process time-consuming and error-prone. Each manual operation increases the chance of inaccuracy, while the need for specific tools and techniques often slows progress, particularly on large-scale projects under tight schedules.

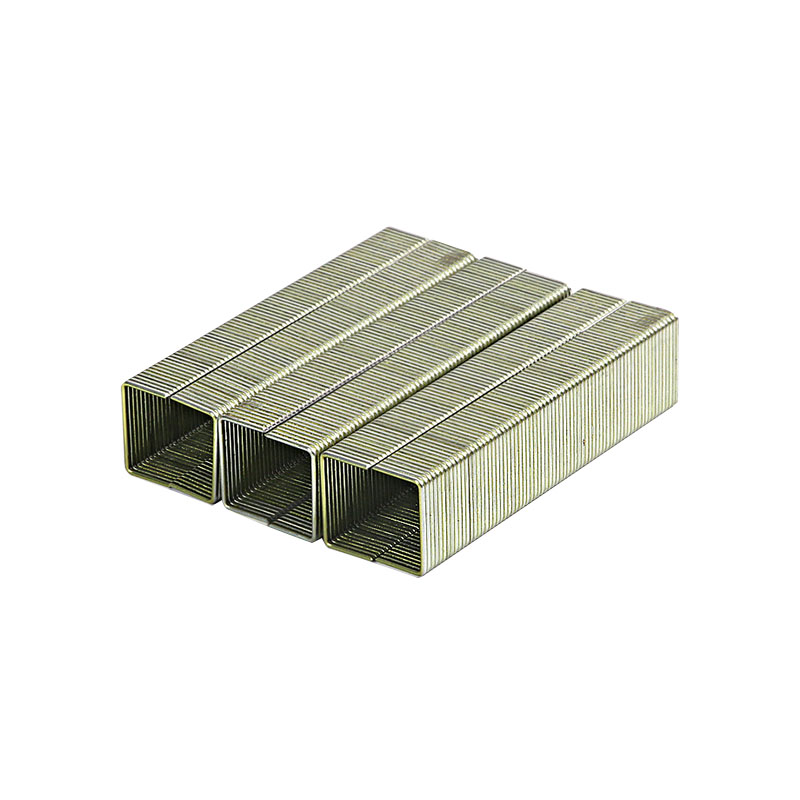

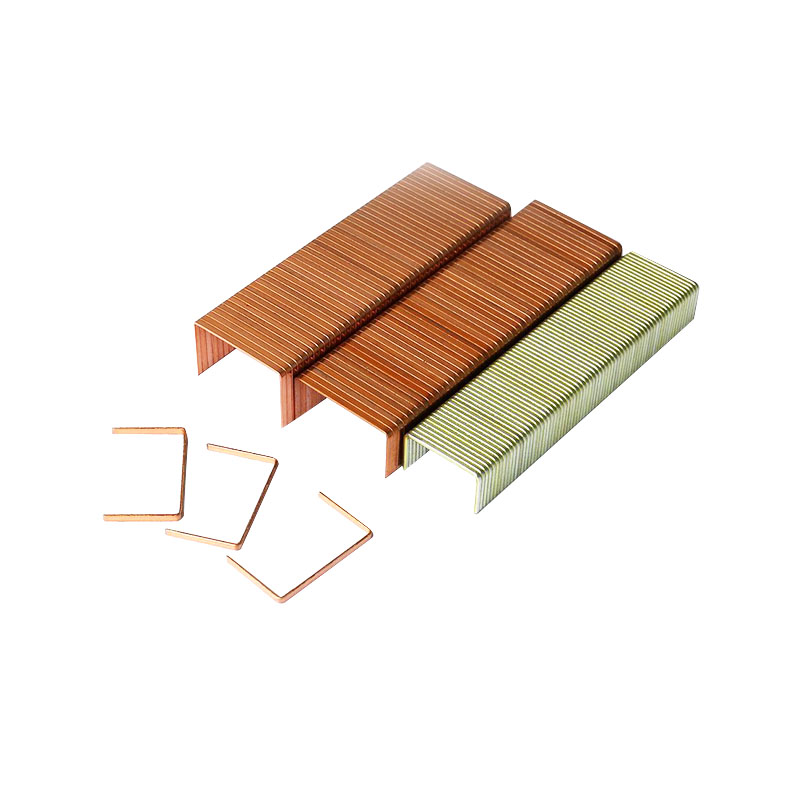

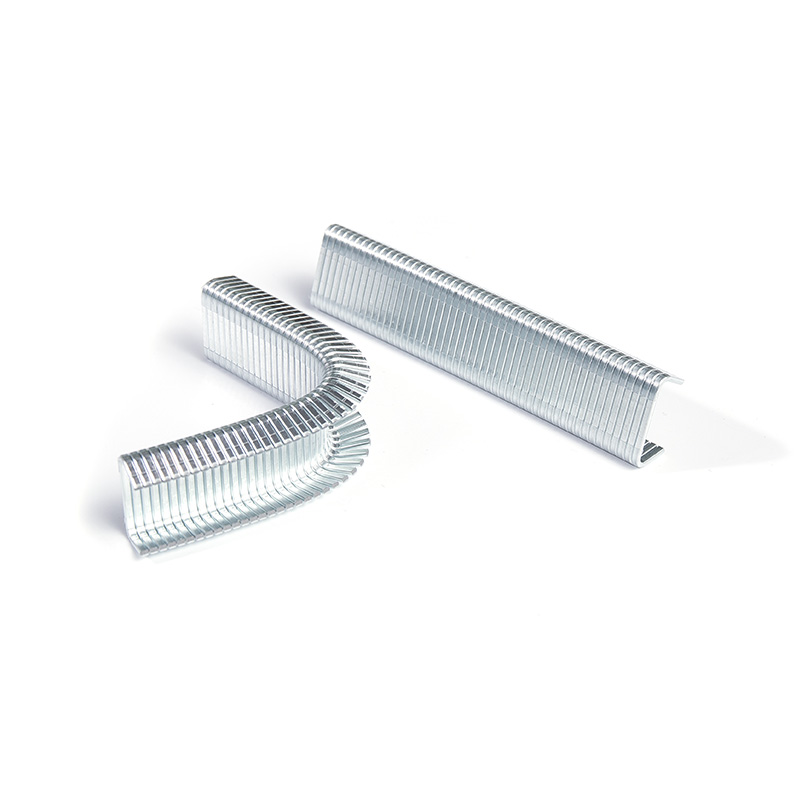

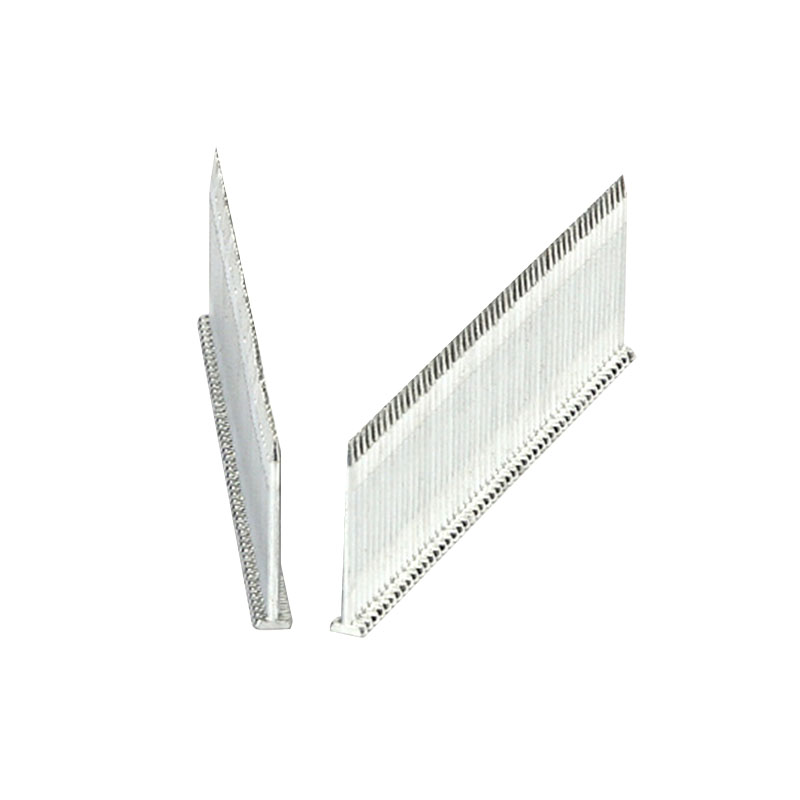

1.2 Intuitive Design Simplifies the Workflow

Fastener Hardware Nails are engineered with ease-of-use in mind. Their unique structural design allows them to be installed quickly with manual or power tools, requiring minimal steps. This simplification drastically reduces preparation time, eliminates redundant procedures, and makes fastening more accessible to workers of varying skill levels.

1.3 Enabling Efficient Execution Without Compromising Quality

By offering a simplified yet reliable installation experience, Fastener Hardware Nails empower construction crews to perform quick and consistent fastening without compromising the integrity of the work. This balance between simplicity and performance reduces fatigue, boosts morale, and helps maintain consistent output across shifts and teams.

2.Speed and Precision Combined: Accelerating Project Timelines with Confidence

2.1 Maximizing Daily Task Completion Rates

With construction deadlines becoming increasingly demanding, every second saved during repetitive operations counts. Fastener Hardware Nails allow workers to perform more fastening operations in less time, which significantly increases daily task completion rates—an essential metric for project managers and contractors under time pressure.

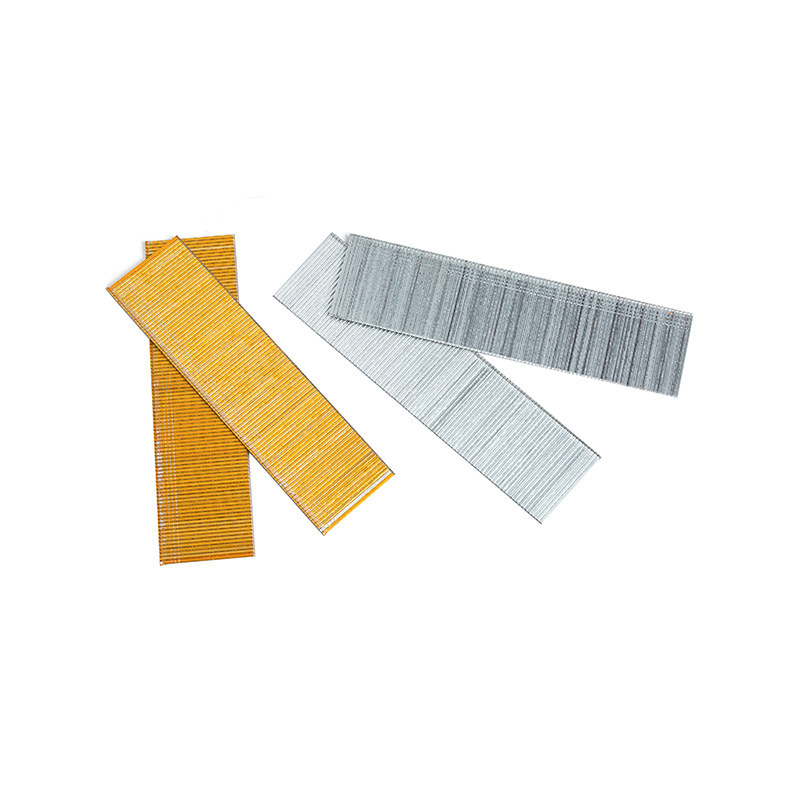

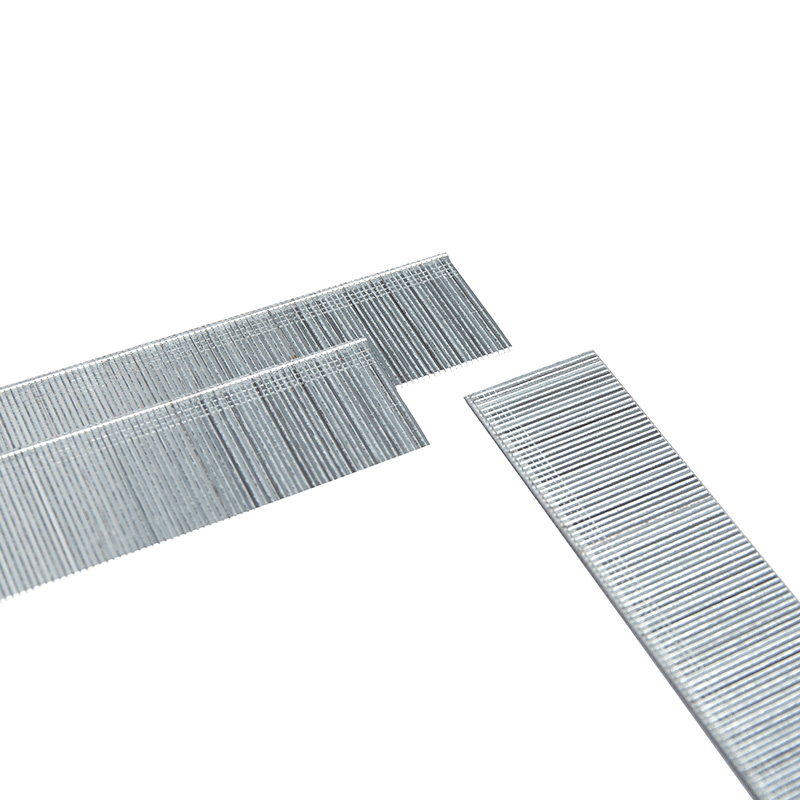

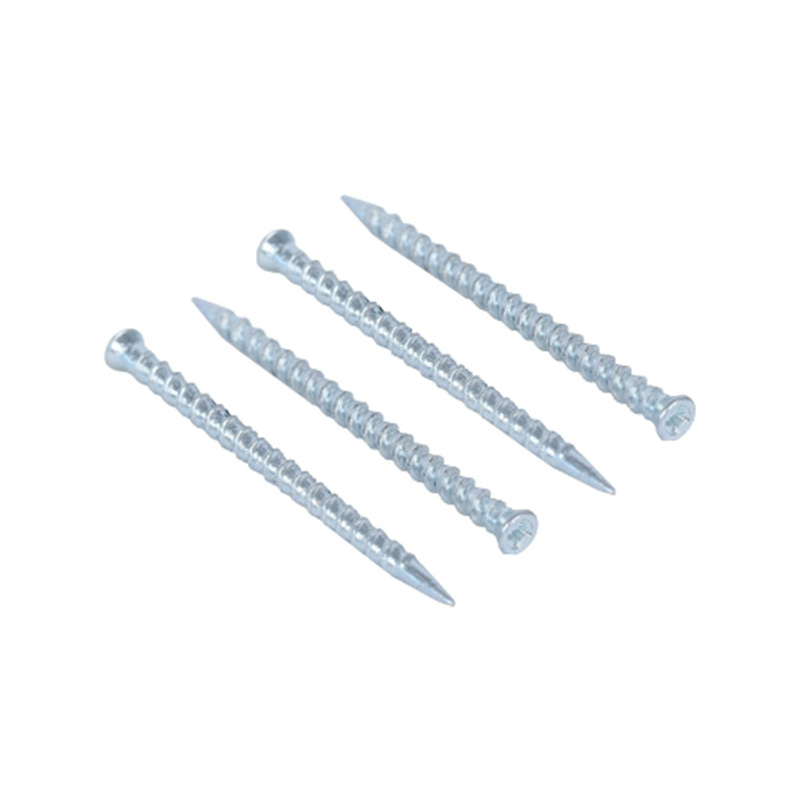

2.2 Shorter Cycles, Stronger Connections

Unlike traditional fasteners that may require adjustments or re-fastening, Fastener Hardware Nails are designed to form accurate, durable connections on first application. Their high grip strength and precise insertion mechanism mean fewer retries and no need for secondary securing methods, leading to shorter installation cycles and fewer quality checks.

2.3 Reliable Under Pressure: Stability Meets Speed

Speed is irrelevant if the result is structurally compromised. Fastener Hardware Nails deliver both—rapid application and secure bonding. Built with high-strength materials and engineered to withstand load and environmental variables, they maintain stability and structural integrity even in dynamic or heavy-load environments.

3.Driving Down Costs: Reducing Labor Dependency While Enhancing Productivity

3.1 Less Labor, Greater Output

By dramatically increasing the speed and simplicity of fastener installation, these nails reduce the need for a large workforce. A smaller team can handle more work, lowering both direct and indirect labor costs and freeing up skilled personnel for other critical areas of the build.

3.2 Reducing Rework and Material Waste

Improper or failed fastener installations are a major contributor to project inefficiencies. Fastener Hardware Nails minimize this risk through their precision design, cutting down on rework, wasted materials, and associated delays. This also improves consistency across teams and job sites, especially when scaling operations.

3.3 Smarter Resource Allocation, Higher Project Efficiency

With less time spent on fastening and fewer workers required per task, project managers gain greater flexibility in allocating resources. The saved labor hours and cost efficiency allow for reinvestment in other project components, driving overall performance and increasing the likelihood of on-time and on-budget project delivery.