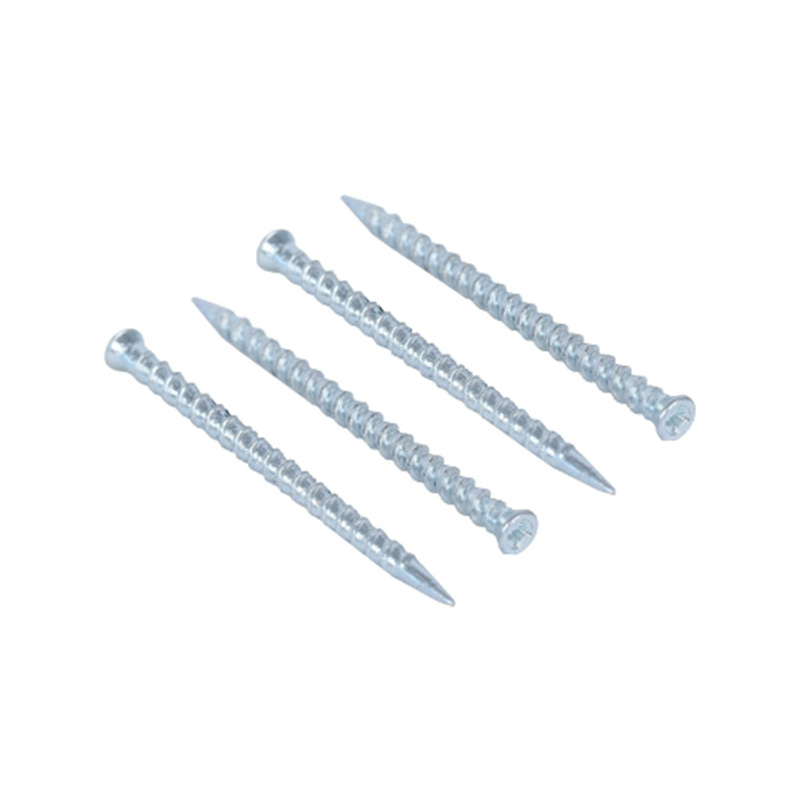

In manufacturing and construction projects in various industries, screws are important connection components and are responsible for ensuring the stability and safety of the structure. However, screws are often exposed to various environmental conditions, especially in environments with moisture, rain erosion or high air humidity. The corrosion problem of traditional screws is often an important factor leading to connection failure and shortened service life. Therefore, the corrosion resistance of screws has become an important criterion for judging their quality and long-term reliability.

1. The importance of corrosion resistance

Screws play a vital role in connection work. They provide the necessary fixing force and stability for various structures. However, in many environments, screws are often attacked by factors such as moisture, rain and oxidation. In particular, screws that are exposed to moisture, high humidity or rainy environments for a long time often experience rust, corrosion, wear and other problems. These problems not only affect the strength and load-bearing capacity of the screws themselves, but may also cause the loosening of the connection structure and even safety hazards.

Traditional metal screws often lose their durability quickly in such environments due to material limitations, showing obvious signs of corrosion. This not only increases the cost of later maintenance and replacement, but also affects the safety and stability of the entire project. Therefore, improving the corrosion resistance of screws is particularly important to ensure long-term stable connection performance and extend service life.

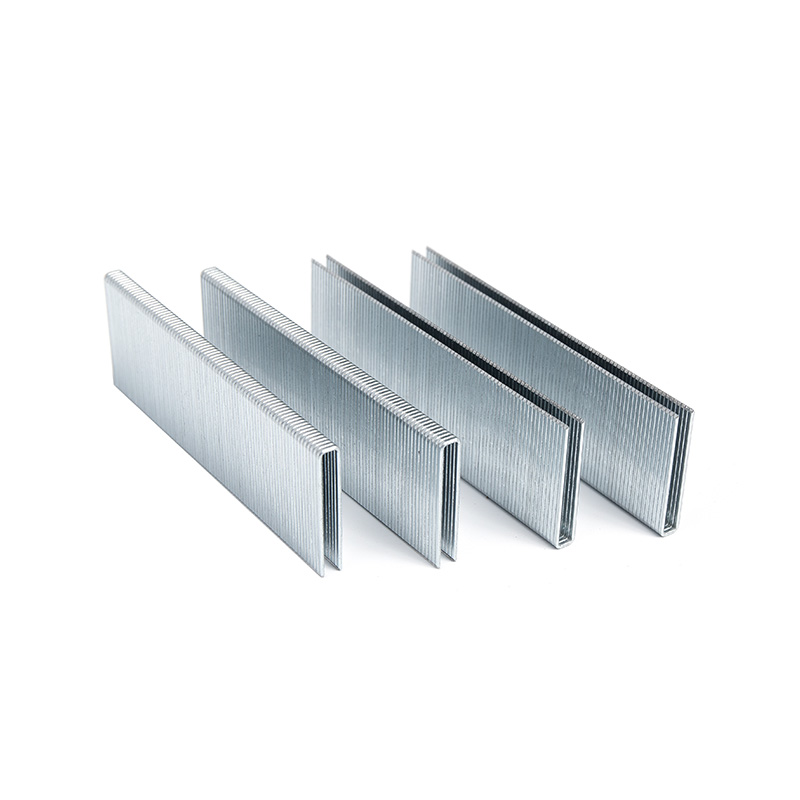

2. Anti-corrosion advantages of Carbon Steel Fiber Screws

Carbon Steel Fiber Screws have become the best choice for preventing screw corrosion due to its excellent anti-corrosion performance. Compared with traditional metal screws, Carbon Steel Fiber Screws adopts advanced surface treatment technology to fundamentally solve the problems of rust and corrosion. Through this innovative technology, Carbon Steel Fiber Screws can significantly improve its corrosion resistance, so that it can still maintain stable connection performance and long service life in humid environments, rain erosion and high humidity conditions.

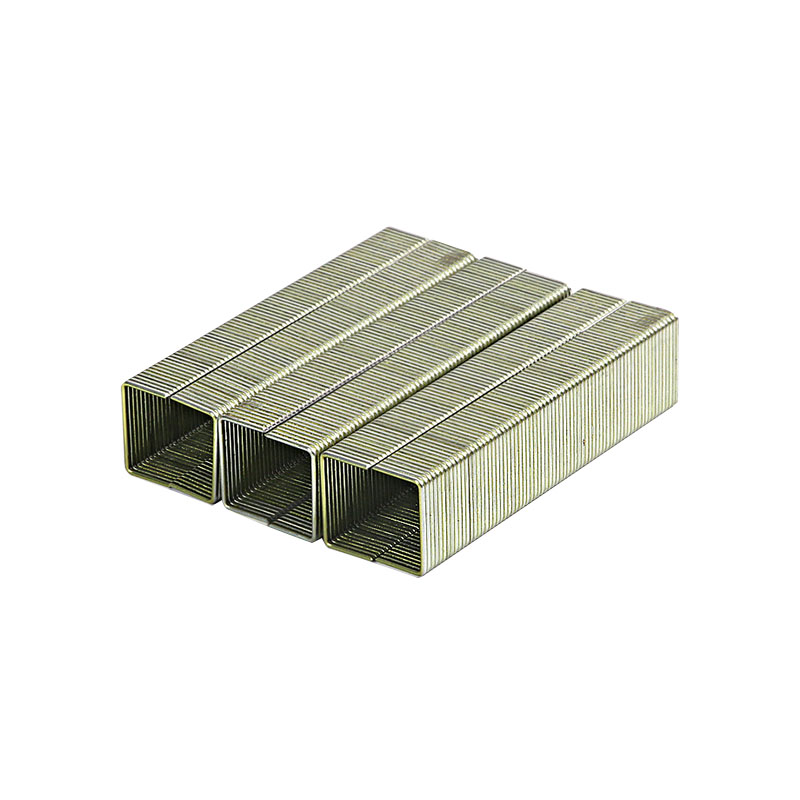

3. Surface treatment technology: prevent oxidation and moisture erosion

The core of the anti-corrosion performance of Carbon Steel Fiber Screws lies in its unique surface treatment process. When traditional screws are exposed to air and moisture, the metal surface will react with oxygen to form oxides or rust, which not only affects the appearance of the screws, but also causes their strength to decrease, thus affecting the stability of the entire connection structure. Carbon Steel Fiber Screws, on the other hand, form a solid protective layer through fine surface treatment. This protective layer can effectively isolate moisture and oxygen in the air, prevent oxidation reactions on the surface of the screws, and ensure the stability and strength of the screws in long-term use.

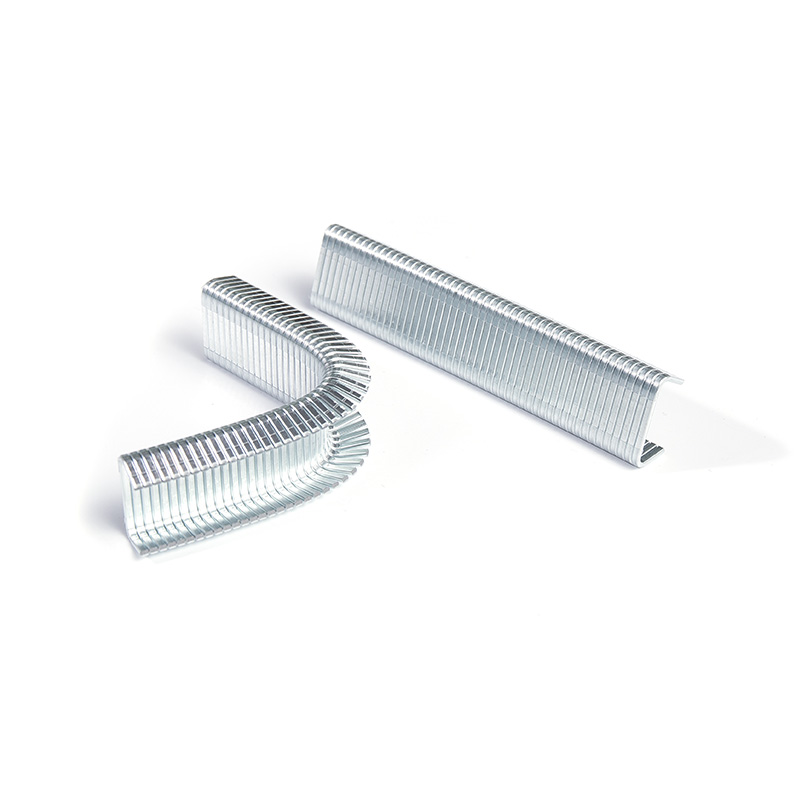

In addition, this surface treatment can also effectively prevent the intrusion of moisture and reduce the risk of corrosion of the screws due to moisture erosion. Even in extreme climatic conditions, Carbon Steel Fiber Screws can still maintain strong corrosion resistance, thereby extending its service life and avoiding safety hazards caused by corrosion.

4. Improve long-term performance and reduce maintenance costs

Due to the improvement of corrosion resistance, Carbon Steel Fiber Screws have shown better stability and reliability in long-term use. After long-term use, traditional metal screws often suffer from strength loss and loss of load-bearing capacity due to corrosion. This forces the project party to frequently inspect, maintain and replace, increasing the long-term maintenance cost of the project.

The corrosion resistance of Carbon Steel Fiber Screws can not only effectively prevent the screws from being damaged by environmental factors, but also extend the service life of the screws. In this way, the project party can reduce the frequency of fault repairs caused by screw corrosion, thereby greatly reducing maintenance costs. In the long run, the use of Carbon Steel Fiber Screws can save a lot of resources and manpower costs for the project and improve the overall benefits of the project.

5. Adapt to a variety of complex environments

The success of a project depends not only on the strength of the screws, but also on its performance in complex environments. Traditional screws often cannot maintain their performance in extreme environments and are susceptible to corrosion, wear or failure. Carbon Steel Fiber Screws, with its excellent corrosion resistance, can maintain good performance in humid, rain erosion or high humidity environments, ensuring that the screws can still work stably under harsh conditions and maintain the integrity of the connection structure.

This high corrosion resistance allows Carbon Steel Fiber Screws to be widely used in various challenging environments. Whether it is construction engineering, mechanical equipment or automobile manufacturing, Carbon Steel Fiber Screws can provide strong and long-term stable connections, avoiding safety hazards and project failures caused by screw corrosion.