The Fundamental Shift in Fastening Technology

The debate between using air gun nails and traditional hammer nails is more than a simple choice of tools; it represents a fundamental shift in construction, carpentry, and DIY methodologies. Efficiency in this context is a multifaceted concept, encompassing not just speed, but also consistency, physical exertion, precision, and long-term project viability. For decades, the hammer was the undisputed symbol of building, requiring skill, strength, and patience. The advent of pneumatic and cordless nail guns introduced a new paradigm, where power from an air compressor or battery drives the fastener into material in a fraction of a second. This article delves deep into a comparative analysis of these two fastening approaches, moving beyond surface-level observations to examine the true impact on workflow, outcome quality, and operator fatigue. We will explore this through specific, user-driven queries like the best air gun nails for framing a house, which highlights the tool's role in large-scale structural efficiency.

Head-to-Head: A Detailed Efficiency Breakdown

To understand the efficiency gap, we must dissect the performance of each system across several critical operational dimensions. The following analysis provides a structured comparison, first described in detail and then summarized for clarity.

Speed and Volume of Work

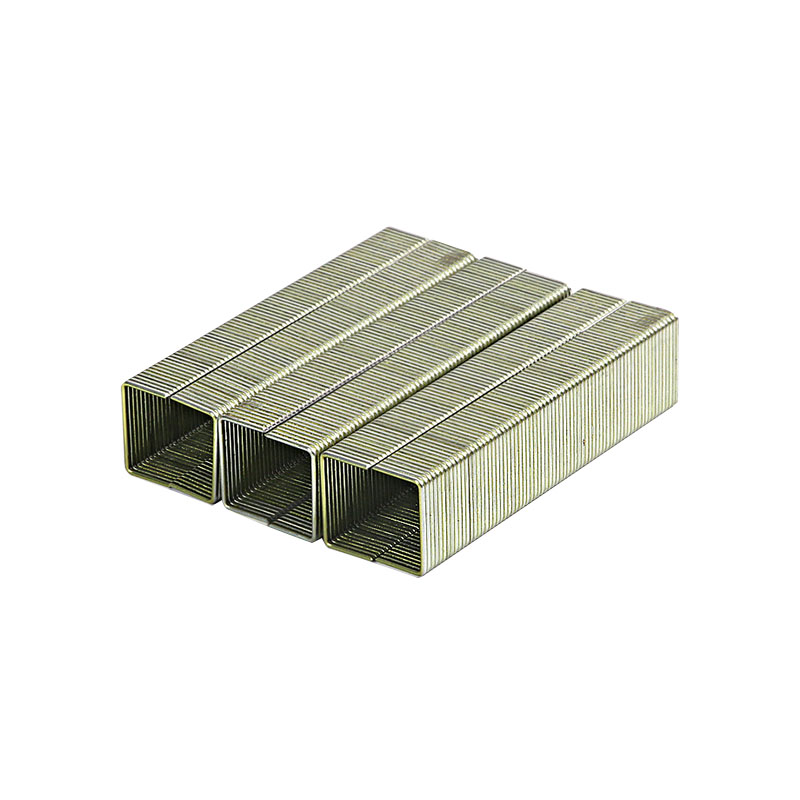

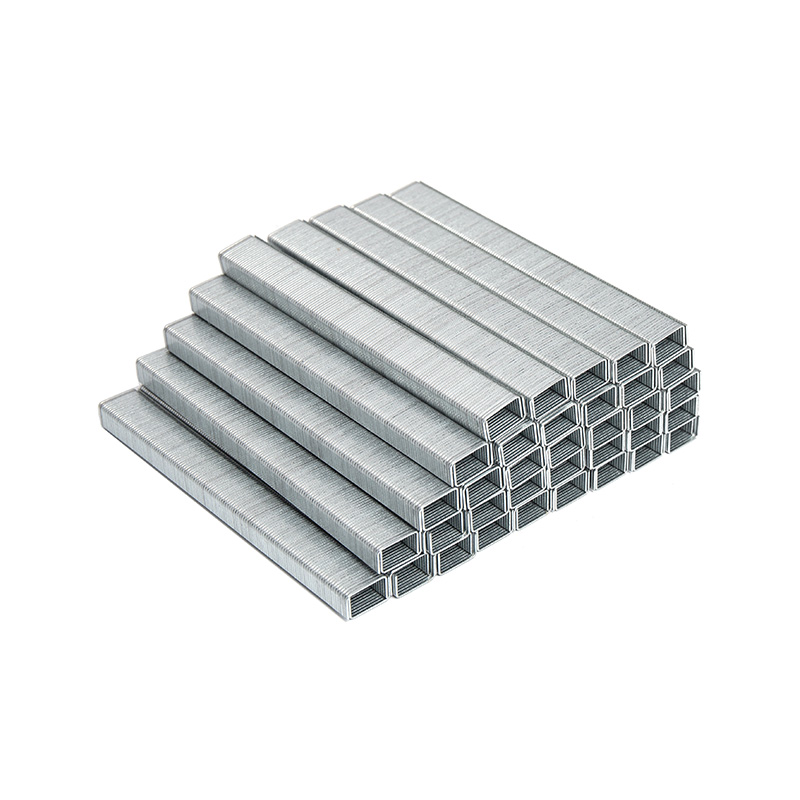

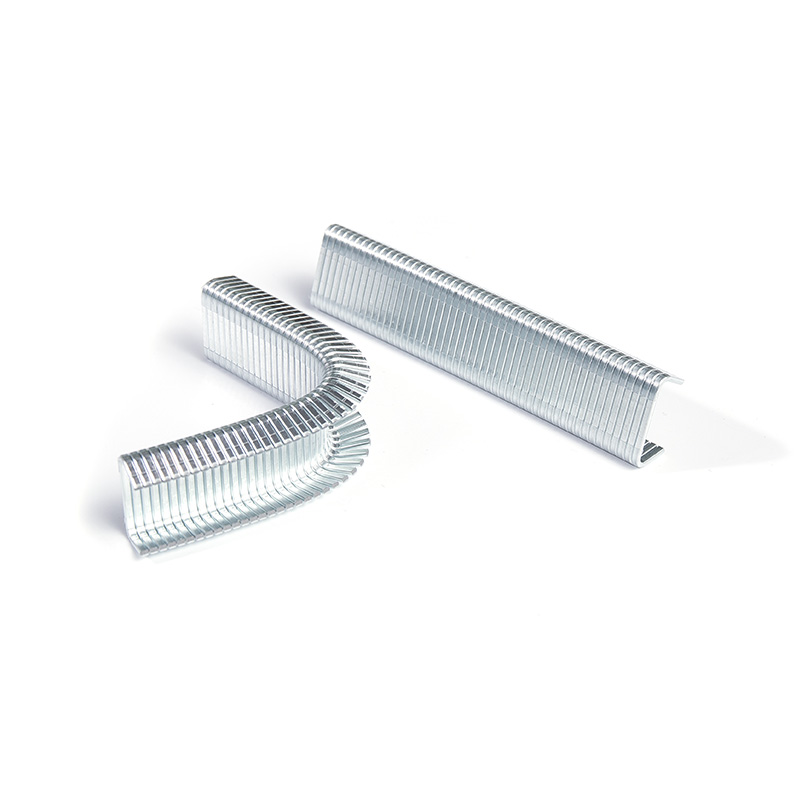

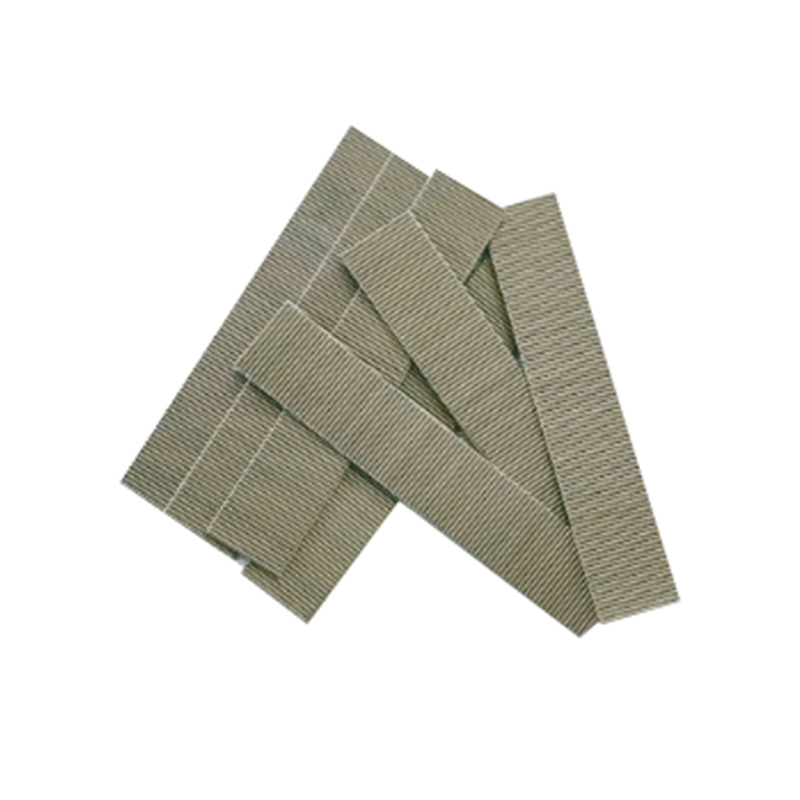

When evaluating pure velocity of fastening, air gun nails operate on a different timescale than hammer nails. A skilled carpenter swinging a hammer can deliver a nail in two to three forceful strokes, taking several seconds per nail when including reach, positioning, and swing. In contrast, a pneumatic nail gun can drive a nail with a single pull of the trigger, a process that takes less than a second from contact to countersink. This difference becomes exponentially significant over hundreds or thousands of fasteners. For instance, in sheathing a roof or installing subflooring, a nail gun allows a worker to maintain a rapid, rhythmic pace, often securing a sheet in minutes versus the half-hour or more required with a hammer. The efficiency isn't just in the firing mechanism but in the reduced handling; nails are loaded in strips or coils, eliminating the need to fumble for individual nails from a pouch. However, this speed advantage assumes a ready supply of air or charge and is most pronounced in repetitive, high-volume tasks. For a single repair or a handful of nails, the time spent setting up the compressor might negate the speed benefit, a consideration often missed when searching for the difference between coil and strip nail guns, as magazine type directly impacts reload frequency and sustained workflow speed.

Physical Demand and User Fatigue

This dimension starkly separates the two methods. Driving nails with a hammer is a full-body kinetic activity. It engages the arm, shoulder, back, and core muscles to generate the force required, especially for larger nails or hardwoods. Over a full workday, this leads to significant muscular fatigue, strain on joints, and the risk of repetitive stress injuries. Moreover, the constant impact vibration transmitted through the handle can contribute to long-term conditions like vibration white finger or carpal tunnel issues. An air nail gun, by contrast, fundamentally changes the operator's role. The tool's motor or pneumatic mechanism provides the driving force. The user primarily provides guidance, stability, and actuation via the trigger. This drastically reduces muscular exertion and impact vibration on the body. The result is the ability to work longer with less fatigue, maintain consistency throughout the day, and reduce the risk of chronic injury. This ergonomic advantage is a critical component of overall project efficiency, as a less fatigued worker makes fewer errors and maintains productivity. This benefit is crucial for prolonged projects, such as when one needs air gun nails for installing hardwood flooring efficiently, where being bent over for hours makes tool weight and ease of operation paramount.

Consistency and Precision of Placement

Precision directly influences both the quality and the speed of work. A hammer relies entirely on the user's skill and steady hand to start the nail straight and drive it flush without bending it or marring the workpiece. Even for experts, slight glancing blows or nail bending can occur, requiring time to pull and replace the fastener. A nail gun offers superior mechanical consistency. The nail is held perfectly straight within the nosepiece, and the driving force is applied along a single, consistent axis. This virtually eliminates bent nails and allows for precise depth control through adjustable settings, ensuring every nail is driven to the exact same depth—critical for tasks like trim work where surface appearance is key. This consistency reduces material waste from damaged nails or wood and minimizes time-consuming corrections. It also enables techniques like pinning that would be exceedingly difficult with a hammer. The importance of this precision is a key reason behind queries for the safety features of a pneumatic nail gun, as the power that enables consistency also demands respect and proper handling to prevent accidental discharge.

| Efficiency Factor | Air Gun Nails | Traditional Hammer Nails |

|---|---|---|

| Speed (High-Volume Tasks) | Extremely High. Can drive multiple nails per second with sequential or bump firing. | Moderate to Slow. Speed depends entirely on user skill and stamina. |

| Physical Demand | Low. Minimal user force required; reduces fatigue and injury risk. | Very High. Requires significant muscular exertion and absorbs impact shock. |

| Consistency & Precision | Very High. Mechanically guided for straight drives and adjustable depth control. | Variable. Highly dependent on user skill; risk of bending or marring. |

| Setup & Mobility | Lower. Requires air compressor, hose, power source, or battery management. | Highest. A hammer is instantly ready and completely portable. |

| Versatility for Small Jobs | Lower. Setup time is often not justified for a few nails. | Higher. The obvious choice for quick repairs and tiny tasks. |

| Initial Financial Outlay | High. Cost of gun, compressor/batteries, and hose. | Very Low. Cost of a hammer and a box of nails. |

Choosing the Right Tool for the Job

Efficiency is not an absolute metric but is defined by the specific context of the task at hand. Therefore, the superior tool is the one that aligns best with the project's scale, precision requirements, and work environment.

Scenarios Where Air Gun Nails Excel

Air-powered and cordless nail guns deliver their most dramatic efficiency gains in predictable, repetitive, and large-scale applications. Their design is optimized for volume and uniformity.

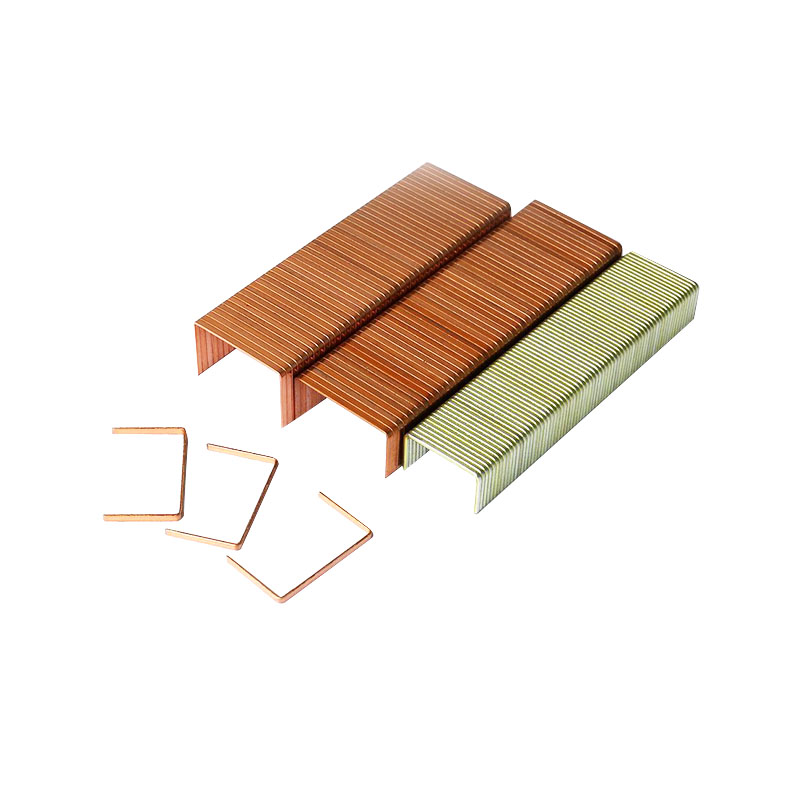

- Framing (Walls, Roofs, Decks): This is the quintessential use case. Driving hundreds of 3-inch nails for wall studs, floor joists, or roof sheathing with a hammer is grueling and time-consuming. A framing nail gun turns this into a swift, manageable process. The ability to rapidly toe-nail or make awkward overhead drives safely is a massive advantage. This directly relates to the search for the best air gun nails for framing a house, as users are seeking the optimal fastener (smooth vs. ring shank, clip vs. coil) to complement the tool's power for maximum structural integrity and speed.

- Sheathing and Subfloor Installation: Similar to framing, attaching large sheets of plywood or OSB requires a high density of fasteners placed at regular intervals. A nail gun with a rapid-fire mode allows a worker to "walk" the gun across the sheet, securing it in a fraction of the time, with consistent depth that prevents "proud" nails that can interfere with subsequent layers.

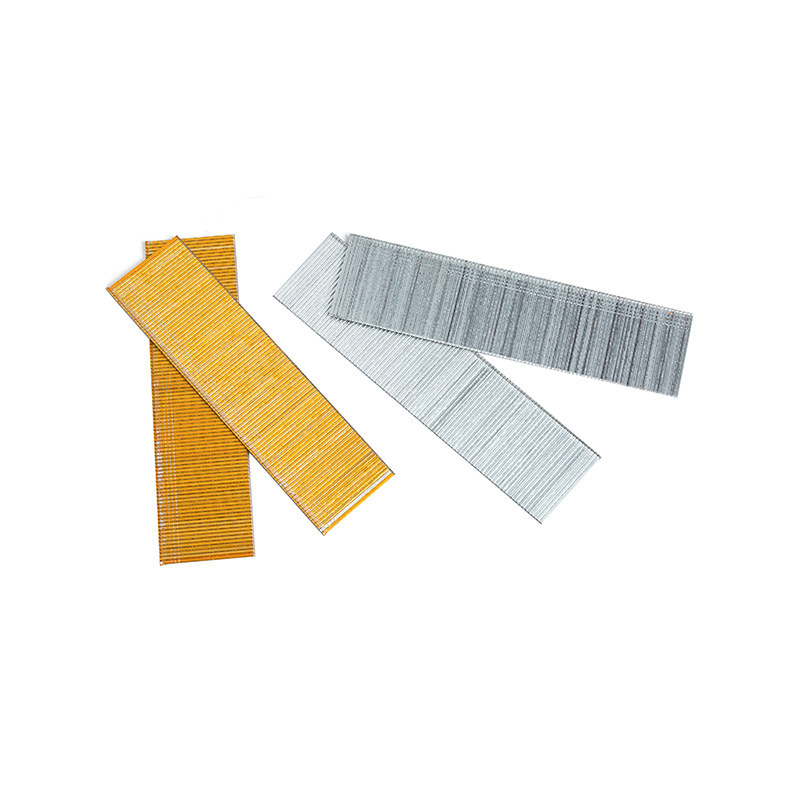

- Finishing and Trim Work: Here, precision is as critical as speed. Finish nailers and brad nailers allow for delicate, near-invisible fastening of crown molding, baseboards, door and window casings, and cabinetry. The small gauge nails leave minimal holes, and the depth control ensures the head is perfectly set below the surface without damaging the delicate wood. This precision is what makes them ideal for air gun nails for installing hardwood flooring efficiently, as they can securely blind-nail tongue-and-groove boards without splitting and with consistent, subtle placement.

- High-Production Environments: Any setting where time is directly linked to cost and output, such as custom furniture workshops, pallet manufacturing, or crate building, sees an immediate return on investment from nail guns due to the sheer volume of fasteners used daily.

Scenarios Where the Traditional Hammer Holds Its Ground

Despite the technological advantages of nail guns, the humble hammer retains a vital and irreplaceable position in the toolbox. Its efficiency lies in its simplicity, immediacy, and versatility for non-standard tasks.

- Small Repairs and One-Off Tasks: Needing to hang a picture, fix a loose fence picket, or assemble a single small box does not justify hauling out a compressor, connecting hoses, and loading a nail strip. The hammer is instantly ready and requires no setup.

- Work in Tight or Awkward Spaces: A hammer can deliver a blow in orientations where a nail gun's nose cannot physically fit or where the tool's body is too cumbersome to maneuver.

- Demolition and Pry Work: The claw hammer is a dual-purpose tool. While a nail gun drives fasteners in, a hammer's claw is essential for pulling them out, prying apart materials, or light demolition work—a function no nail gun can replicate.

- When Absolute Control is Paramount: For ultra-fine work, such as setting the final nail in a delicate piece of trim where the risk of a nail gun's power causing damage is too high, a skilled hand with a hammer and nail set provides the ultimate finesse and tactile feedback.

- Low-Budget or Infrequent Use: For the occasional DIYer or someone on an extremely tight budget, the low cost of a quality hammer versus a full nail gun system makes it the efficient financial choice.

Critical Considerations Beyond the Initial Drive

A comprehensive efficiency analysis must look past the moment the nail is set. Factors like cost, safety, and maintenance play a long-term role in determining the true value of a fastening system.

Cost Analysis: Initial Investment vs. Long-Term Value

The financial aspect presents a clear trade-off. The startup cost for a nail gun system is substantially higher. You must purchase the nail gun itself, and for pneumatic models, a compatible air compressor and hose. Cordless models eliminate the compressor but come with a higher tool price and the need for expensive batteries and chargers. In contrast, a professional-grade hammer and a box of nails represent a minimal initial outlay. However, the long-term value calculation shifts when factoring in labor time and scale of work. For professional contractors, the time saved on every project by using a nail gun can quickly recoup the initial investment through the ability to take on more work or reduce labor hours billed. For a high-volume hobbyist, the value may be in reduced project time and physical strain. The ongoing consumable cost—the nails themselves—is comparable between systems, though nail gun nails are often slightly more expensive per unit due to their collated form. Understanding the difference between coil and strip nail guns is part of this cost analysis, as coil guns hold more nails (reducing reloads) but the nails can be more expensive and the guns are often bulkier.

Safety and Operational Awareness

Efficiency is meaningless if it compromises safety. This is a major differentiator. A hammer's primary risk is a misplaced thumb or a flying nail, generally causing localized injury. A nail gun, however, is a powerful tool capable of driving a fastener through hard wood and even metal with enough force to cause severe, life-threatening injuries. Safe operation is non-negotiable and requires specific knowledge. Key safety features of a pneumatic nail gun include sequential trip triggers (which require deliberate steps to fire, reducing accidental discharge), contact trip triggers (for rapid firing, but with higher risk), lock-off switches, and exhaust deflectors. Proper training on handling, never pointing the tool at anything you don't intend to nail, keeping hands clear, and disconnecting the air supply when loading or clearing jams is crucial. The efficiency gain of a nail gun is only sustainable if paired with rigorous safety practices to prevent catastrophic accidents that halt work entirely.

Maintenance and Operational Logistical

The reliability of your tool affects workflow efficiency. A hammer requires almost no maintenance—perhaps an occasional sanding of a splintered handle or tightening of the head. A nail gun is a mechanical system that demands care. Pneumatic tools require regular lubrication, cleaning of the air inlet filter, and ensuring the compressor's tank is drained of moisture to prevent internal corrosion. Hoses can get damaged or become trip hazards on a worksite. Cordless guns require battery management—keeping them charged, stored properly, and eventually replaced. Furthermore, logistical setup is a factor. Moving a compressor around a job site, managing hose length, and ensuring access to power adds a layer of planning that doesn't exist with a hammer. The efficiency payoff comes from streamlining these logistics, such as using a portable compressor for smaller sites or investing in a long-life battery system. A question like how to choose the right gauge for brad nailer projects ties into this, as using the wrong nail (e.g., too thick a gauge for hardwoods) can lead to jams, splitting, and downtime, directly impacting the smooth, efficient operation the tool is meant to provide.

The Verdict on Modern Fastening Efficiency

In the final analysis, declaring one method universally more efficient than the other is overly simplistic. The true measure of efficiency is contextual. For professional contractors, builders, and serious DIY enthusiasts engaged in large-scale construction, framing, sheathing, or finish work, air gun nails represent a monumental leap forward in efficiency. The combination of blistering speed, dramatically reduced physical fatigue, and superior consistency delivers quantifiable benefits in time saved, quality improved, and worker well-being enhanced. However, this comes with a higher barrier to entry in terms of cost, safety knowledge, and maintenance. Conversely, the traditional hammer remains the paragon of efficiency for small-scale tasks, quick repairs, low-budget projects, and situations demanding ultimate versatility or delicate touch. Its zero-setup, zero-maintenance, and all-purpose nature ensure its permanent place in the toolbox. The most efficient practitioners are not those who exclusively use one tool, but those who understand the strengths and limitations of both, mastering the hammer for its intended purposes and harnessing the transformative power of the nail gun for the tasks where it truly shines, all while prioritizing safety and proper technique above all else.