What Are Heavy Wire Staples and Their Common Applications?

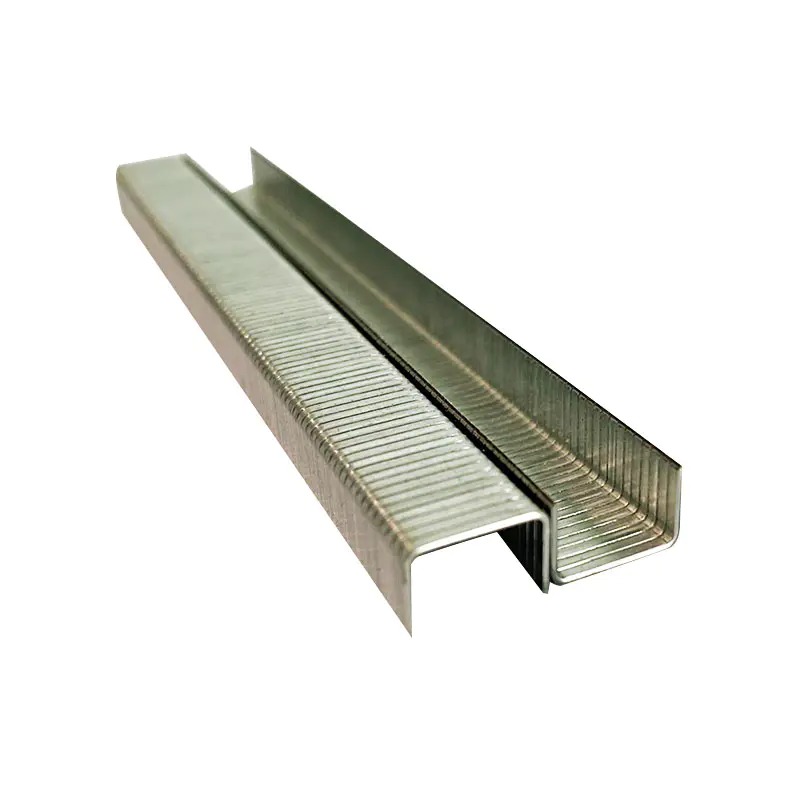

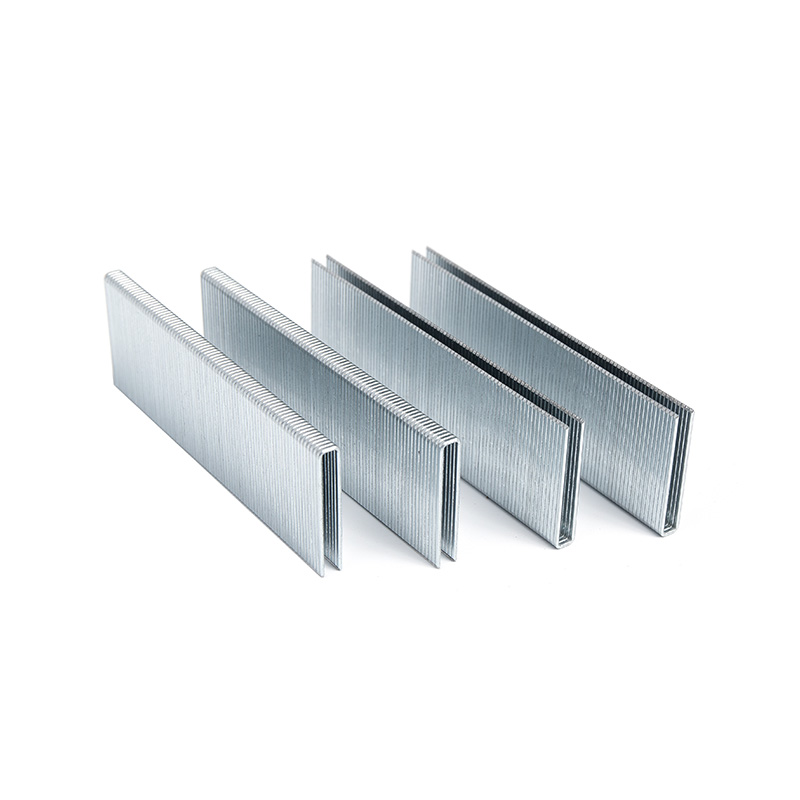

Heavy wire staples are robust fasteners designed for demanding applications where standard staples may fail. These staples are crafted from thick-gauge wire, making them ideal for heavy-duty tasks that require superior holding power and durability.

Primary Uses of Heavy Wire Staples

These staples serve numerous purposes across various industries:

- Construction: Securing roofing felt, insulation, and wire mesh

- Fencing: Attaching wire fencing to wooden posts

- Furniture Making: Reinforcing joints in heavy furniture

- Packaging: Securing heavy cartons and crates

- Agriculture: Fastening vineyard wires and farm equipment

Advantages Over Regular Staples

When comparing heavy wire staples to standard staples, several key differences emerge:

| Feature | Heavy Wire Staples | Regular Staples |

|---|---|---|

| Wire Gauge | 12-16 gauge | 18-22 gauge |

| Holding Power | Excellent for heavy materials | Suited for light materials |

| Durability | Resists bending and breaking | More prone to deformation |

Best Heavy Duty Staples for Fencing: A Comprehensive Guide

When it comes to fencing projects, selecting the best heavy duty staples for fencing is crucial for long-lasting results. The right staples can mean the difference between a fence that withstands years of weather and one that fails prematurely.

Key Features of Quality Fencing Staples

Excellent fencing staples share several important characteristics:

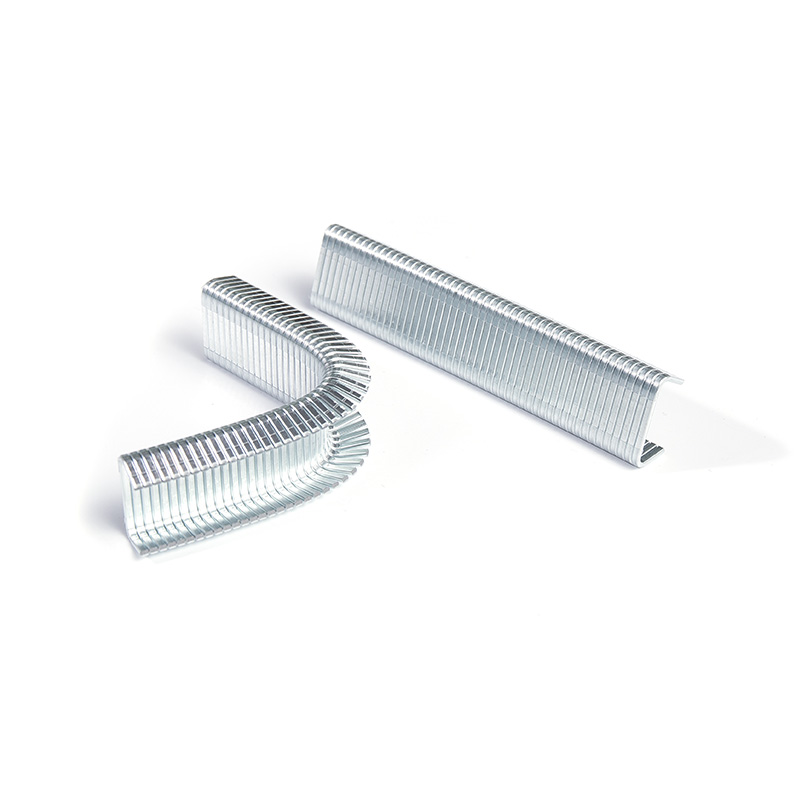

- Galvanized or stainless steel construction for rust resistance

- Proper crown width to securely hold fencing material

- Sharp points for easy penetration into tough wood

- Sufficient length to provide deep anchoring

Comparison of Fencing Staple Types

Different fencing applications require specific staple types:

| Staple Type | Best For | Recommended Length |

|---|---|---|

| U-shaped | Wire mesh fencing | 1" to 1.5" |

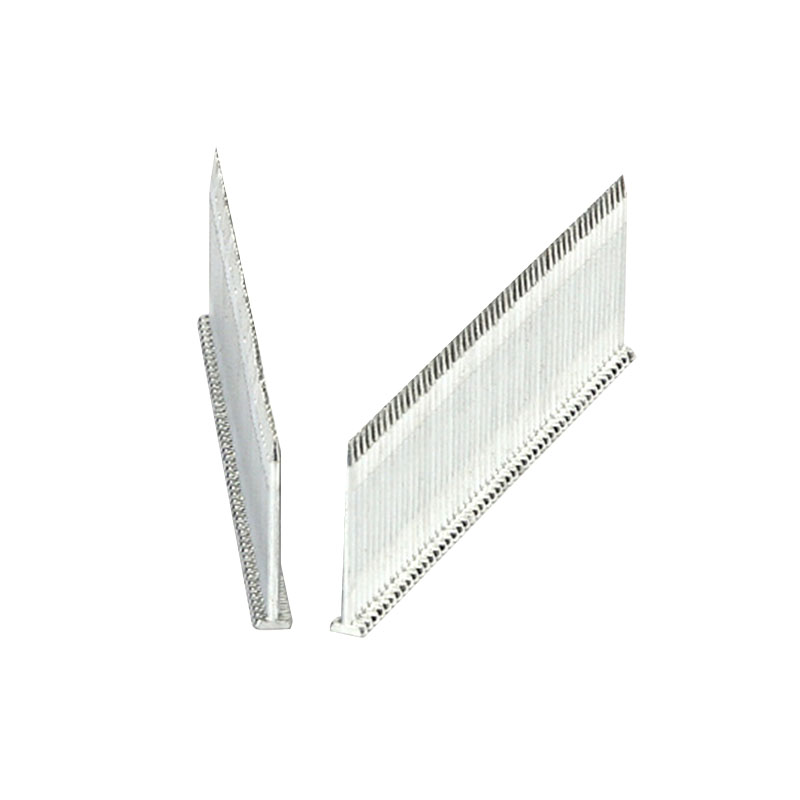

| T-shaped | Barbed wire fencing | 1.5" to 2" |

| Round Crown | Electric fencing | 1.25" to 1.75" |

Heavy Gauge Staple Gun Compatibility: What You Need to Know

Understanding heavy gauge staple gun compatibility is essential before purchasing staples. Not all staple guns can handle the thick wire used in heavy-duty staples, and using incompatible combinations can damage tools or produce poor results.

Types of Staple Guns for Heavy Staples

Three main types of tools can handle heavy gauge staples:

- Manual staple guns: Suitable for light to medium heavy-duty tasks

- Electric staple guns: Good for consistent medium-duty applications

- Pneumatic staple guns: Best for professional heavy-duty use

Key Compatibility Factors

Several factors determine whether staples will work with your gun:

| Factor | Importance | What to Check |

|---|---|---|

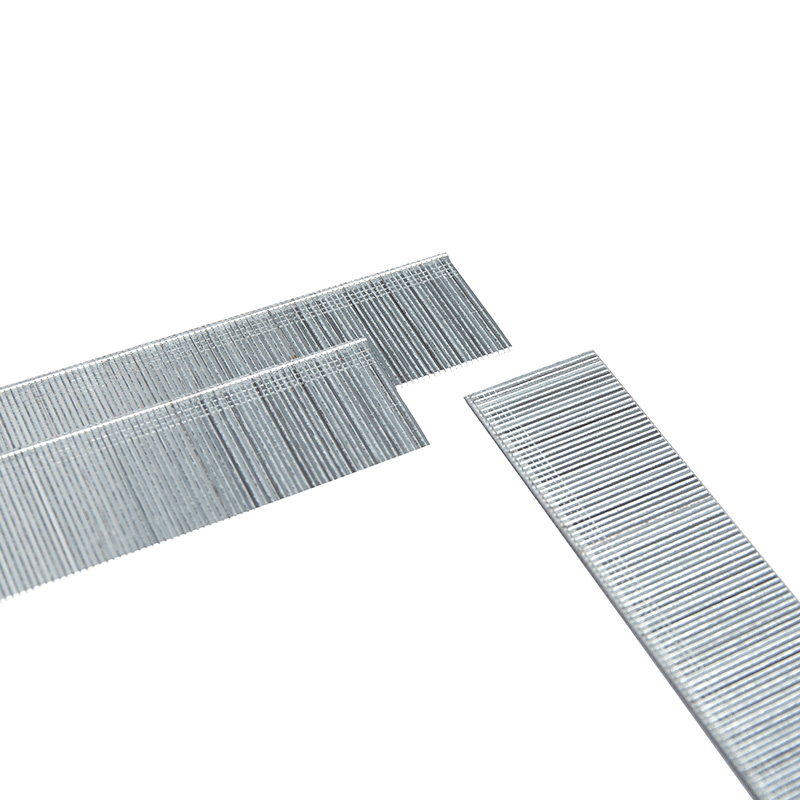

| Crown Width | Critical | Must match gun's magazine |

| Leg Length | Important | Must be within gun's range |

| Wire Gauge | Essential | Must not exceed gun's capacity |

Galvanized Heavy Duty Staples vs Regular: Which Should You Choose?

The debate between galvanized heavy duty staples vs regular staples comes down to application requirements and environmental factors. Galvanized staples offer superior corrosion resistance but at a higher cost.

When to Choose Galvanized Staples

Galvanized staples are worth the investment in these situations:

- Outdoor applications exposed to weather

- High humidity or coastal environments

- Applications where rust could compromise structural integrity

- Projects requiring long-term durability

Comparison of Staple Finishes

Different finishes offer varying levels of protection:

| Finish Type | Protection Level | Best Use Case |

|---|---|---|

| Electro-galvanized | Basic rust resistance | Indoor or temporary outdoor use |

| Hot-dipped galvanized | Superior corrosion resistance | Permanent outdoor installations |

| Stainless steel | Maximum protection | Marine or harsh chemical environments |

How to Choose the Right Size Heavy Wire Staples for Your Project

Understanding how to choose the right size heavy wire staples is crucial for project success. The wrong size can lead to poor holding power or damage to materials.

Key Sizing Considerations

Four main factors determine proper staple size:

- Material thickness being fastened

- Base material density (hardwood vs softwood)

- Required holding strength

- Staple gun compatibility

Staple Size Guide for Common Applications

This reference table helps select appropriate sizes:

| Application | Recommended Crown Width | Recommended Leg Length |

|---|---|---|

| Roofing felt | 1/2" to 3/4" | 3/8" to 1/2" |

| Wire fencing | 1/2" to 1" | 1" to 1.5" |

| Furniture assembly | 1/4" to 1/2" | 1/2" to 3/4" |

Proper Techniques for Installing Heavy Wire Staples

Correct installation methods ensure heavy wire staples perform as intended and maintain their holding power over time.

Installation Best Practices

Follow these guidelines for optimal results:

- Always wear appropriate safety gear

- Position staples perpendicular to the grain in wood

- Use sufficient force to fully seat the staple

- Space staples appropriately for the application

- Avoid overdriving which can bend staples

Common Installation Mistakes to Avoid

These errors can compromise your project:

| Mistake | Consequence | Solution |

|---|---|---|

| Using staples that are too short | Poor holding power | Select longer staples |

| Overdriving staples | Bent or damaged staples | Adjust tool pressure |

| Improper spacing | Uneven stress distribution | Follow manufacturer spacing |