1. Boosting On-Site Productivity: How Industrial Brad Nails Enhance Construction Efficiency

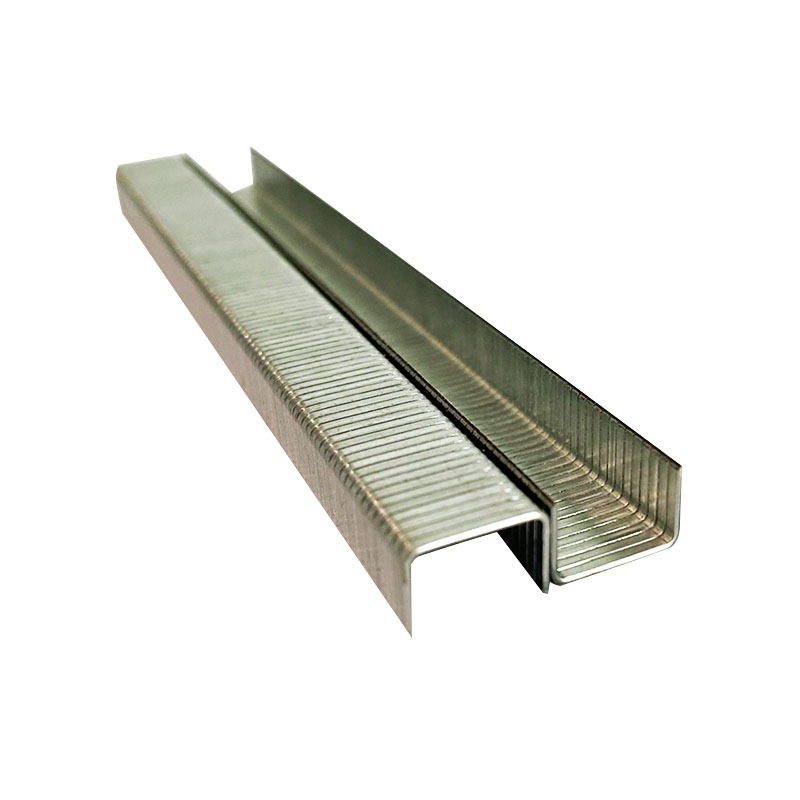

1.1 Precision Engineering for Faster Nailing

Industrial Brad Nails feature a slender, finely crafted body and a small nail head that allow them to be driven into materials with minimal resistance. This design minimizes the need for force, reducing physical strain on workers and speeding up the nailing process. Their smooth entry into wood and composite materials means less repositioning and fewer misfires—ideal for high-paced job sites.

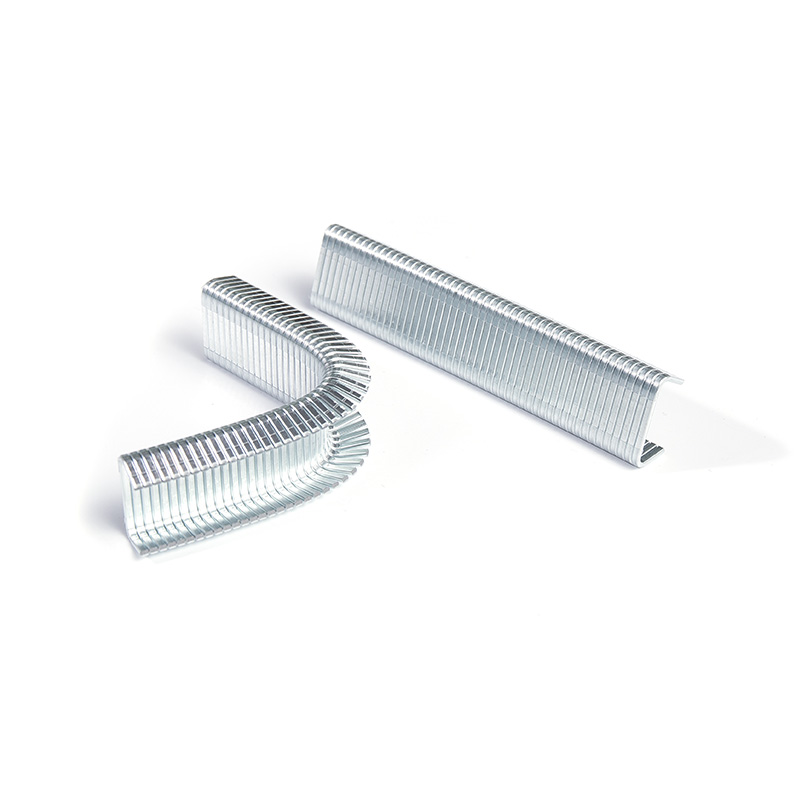

1.2 Streamlined Workflow with Minimal Adjustments

Traditional nails often require re-alignment or cause surface damage due to their size and impact. Industrial Brad Nails penetrate cleanly, holding materials securely without splintering or shifting. This leads to uninterrupted workflow, consistent placement, and reduced tool switching or re-nailing—ultimately increasing overall construction speed.

1.3 Time-Saving Alternative for Interior and Exterior Projects

Whether used for interior moldings or exterior panels, Industrial Brad Nails reduce preparation and post-work steps. By simplifying the nailing process and decreasing error margins, they allow contractors to meet tight deadlines without compromising craftsmanship. The result is a smoother project timeline with fewer delays due to hardware issues.

2. Minimizing Repairs: Creating Cleaner Finishes with Less Effort

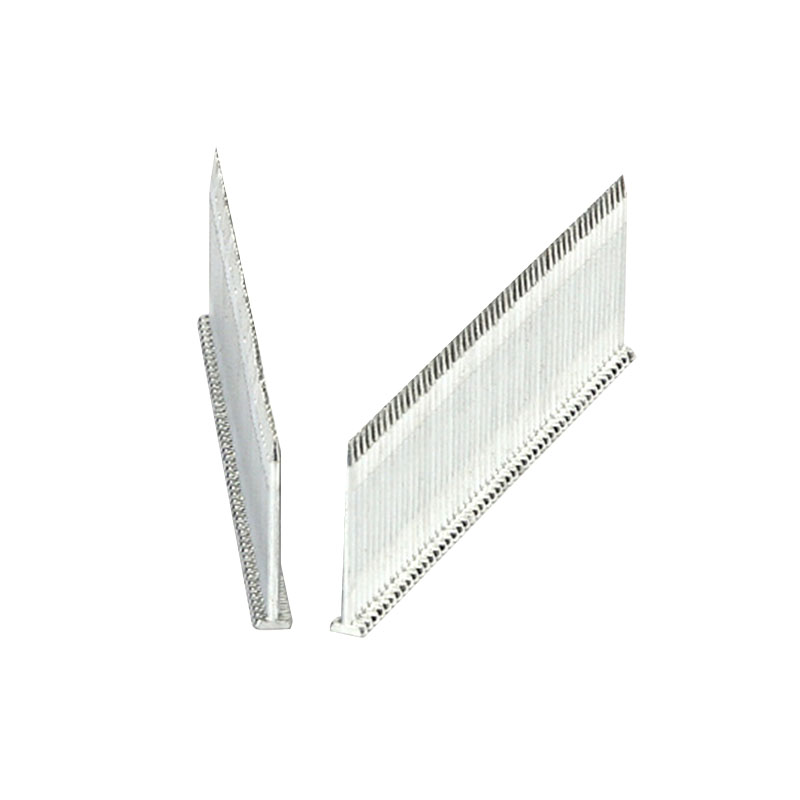

2.1 Nearly Invisible Nail Holes for Flawless Surfaces

One of the standout features of Industrial Brad Nails is the almost invisible entry points they leave behind. Unlike traditional nails that require visible surface patching, Brad Nails create tiny, shallow holes that often need no filler, especially in hidden joints or low-visibility zones.

2.2 Reduced Labor on Cosmetic Touch-Ups

Because of the minimal surface disruption, projects using Brad Nails require less sanding, filling, or repainting. This can save hours of labor, especially in projects with intricate trim work or premium hardwood finishes. Painters and finishers can proceed with final coatings immediately after nailing, accelerating project turnover.

2.3 A Game-Changer for High-Precision Builds

For cabinetry, decorative millwork, and luxury interior applications, where every surface detail counts, Industrial Brad Nails provide a clean finish that aligns with premium aesthetics. Their ability to eliminate unsightly blemishes means fewer callbacks from clients and a higher level of satisfaction with the end product.

3. Elevating Value: How Industrial Brad Nails Improve Overall Project Cost-Effectiveness

3.1 High-Efficiency Performance Lowers Total Labor Hours

By enabling faster application and reducing follow-up work, Industrial Brad Nails contribute to significant savings in labor hours. Fewer repairs and touch-ups mean skilled workers can allocate their time to more value-adding tasks, increasing daily productivity and decreasing project overheads.

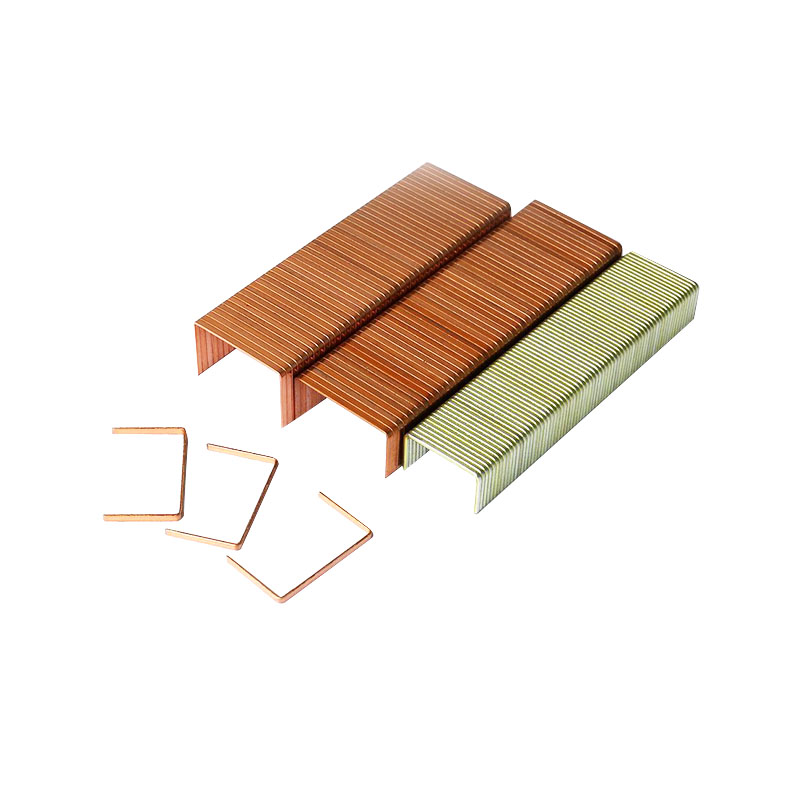

3.2 Cost Reduction Through Material Conservation

Repair work often leads to waste—both in time and in materials like wood filler, extra paint, or replacement boards. With Brad Nails, the precise insertion and clean finish reduce the need for these additional resources. This results in a leaner, more cost-effective construction process that benefits both contractors and clients.

3.3 Ideal for Scalable and Custom Projects Alike

Whether for mass-produced furniture lines, home renovations, or high-end bespoke woodworking, the consistency and efficiency offered by Industrial Brad Nails improve scalability and project ROI. Their durability, ease of use, and minimal impact on finishes make them a reliable choice for projects aiming to balance cost, speed, and quality.