1. Introduction

1.1 Problems and hidden dangers caused by loose floor screws

As an important part of the building and home environment, the stability of the floor directly affects the safety and comfort of living or use. However, loose floor screws are a common and easily overlooked problem. Loose screws will cause the gap between floor panels to increase, local shaking, and even cause the floor to crack or deform. This not only affects the appearance, but also may bring safety hazards, such as tripping and falling accidents. In addition, loose screws will accelerate the damage of the floor and its supporting structure, shorten the service life of the floor, and increase the cost of repair and replacement.

1.2 The key role of screw tightening in floor stability

As a key part for floor installation and fixation, the degree of tightening of screws directly determines the overall stability and durability of the floor. Good screw tightening can effectively prevent loosening and displacement between floor panels and ensure the integrity of the floor structure. At the same time, tightening screws can also effectively disperse external pressure and load, improve the load-bearing capacity of the floor, and reduce structural damage caused by stress concentration. It can be seen that Prevent loose floor screws is to prevent the loosening of floor screws, which is the basic work to ensure the safety and performance of the floor.

2. Analysis of the main reasons for loosening floor screws

2.1 Material fatigue and wear

During long-term use, the screws and surrounding wood or base materials will suffer fatigue damage due to repeated loads and small vibrations. The screws themselves may undergo elastic deformation and lose their tightening force; the wood may crack and compress, resulting in an increase in the diameter of the screw hole and an inability to firmly grasp the screw. The wear process continues to accumulate, eventually leading to the loosening of the screws.

2.2 Improper installation process

The installation link is a key link in Prevent loose floor screws. Incorrect installation methods, such as screws not being tightened in place, using inappropriate screw models or specifications, and not cleaning the installation surface to cause thread stripping, will all lead to the failure of the screws to achieve good tightening. Inexperienced or improper tool selection by some construction workers will also increase the risk of screw loosening.

2.3 Influence of environmental factors (temperature changes, humidity, etc.)

Floors and screws are significantly affected by changes in ambient temperature and humidity. Temperature changes cause materials to expand or contract, and humidity fluctuations cause wood to expand or shrink due to moisture absorption, which will produce structural stress. This repeated change can easily cause screws to loosen, especially in areas with distinct seasons and high humidity.

2.4 Vibration and impact during use

In daily use, vibrations and impacts such as furniture movement, footsteps, and heavy objects falling will continuously act on the floor structure. Continuous mechanical impact will cause the screws to micro-move and gradually loosen, especially in high-frequency use environments.

3. Common methods to prevent loose floor screws

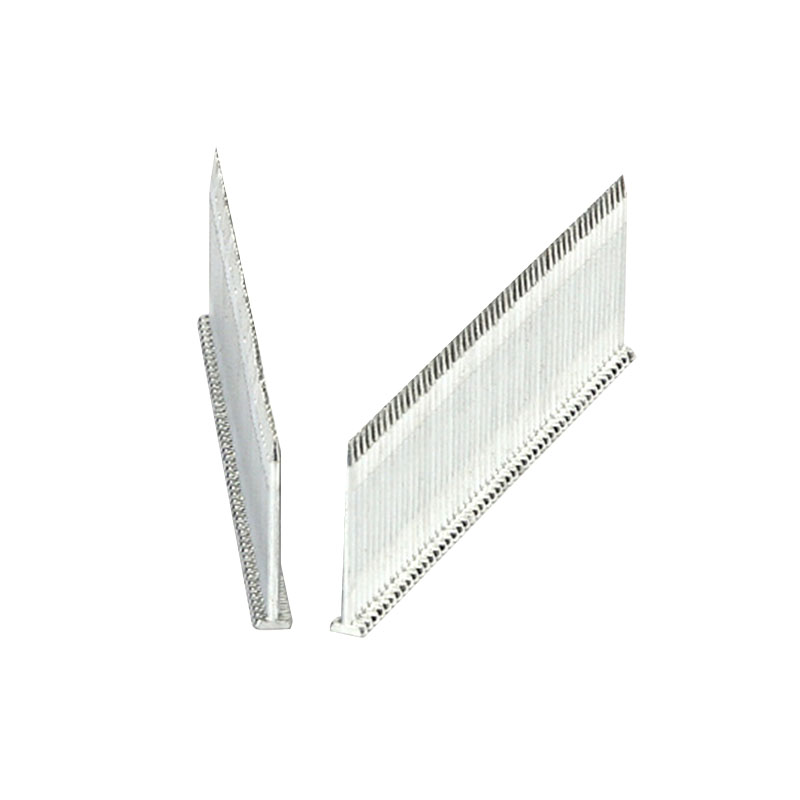

3.1 Use anti-loosening screw design

Anti-loosening screws enhance the tightening force through special structural design, such as thread widening, tooth design, special treatment of screw heads, etc. These structures can effectively resist loosening caused by vibration and impact. Choosing anti-loosening screws suitable for floor installation can fundamentally improve the bonding strength between screws and boards and reduce the probability of loosening.

3.2 Reasonable selection of fastening tools and techniques

The selection and use of screw fastening tools are crucial to prevent loose floor screws. Using torque-controlled power tools can ensure that the screws reach the appropriate tightening force to avoid being too loose or too tight. The correct tightening sequence and force can also evenly distribute stress and reduce the risk of loosening.

3.3 Use auxiliary fixing measures (glue, washers, etc.)

Using special glue, tape or sealant at the interface between screws and wood can increase friction and adhesion to prevent screws from loosening due to vibration. Washers can disperse pressure, protect wood from being crushed by screws, maintain stable apertures, and enhance tightening effects. The use of a variety of auxiliary measures can significantly improve the anti-loosening performance.

3.4 Regular inspection and maintenance

Prevent loose floor screws is not a one-time job, but a continuous process. Regularly check the tightness of floor screws, and tighten or replace them in time if they are loose to prevent small problems from turning into big hidden dangers. Maintenance work should be included in the building or home management plan to ensure long-term stability.

4. Application of science and technology in anti-loosening

4.1 Material innovation and performance improvement

With the development of material science, high-performance alloy materials and composite materials are used in screw manufacturing, which improves the strength, corrosion resistance and fatigue resistance of screws. At the same time, according to the special properties of wood and composite flooring, more suitable screw specifications and surface treatment technologies are developed to effectively improve the fastening effect.

4.2 Development trend of fastening technology

Modern fastening technology not only focuses on mechanical properties, but also pays more attention to installation convenience and safety. Technologies such as intelligent torque control and automatic loosening detection are gradually popularized, assisting construction personnel to achieve more accurate screw fastening, improve installation quality, and reduce human error rate.

4.3 Application of intelligent monitoring technology in screw loosening prevention

In recent years, the development of sensors and Internet of Things technology has provided new ideas for monitoring the loosening of floor screws. By installing stress sensors at key locations, real-time monitoring of fastening status and vibration conditions, remote early warning and maintenance guidance can be achieved, and the scientificity and timeliness of floor maintenance can be improved.

5. The impact of Prevent loose floor screws on the service life of the floor

5.1 Improve the overall stability of the floor structure

Preventing screws from loosening can ensure the close connection between the floor panels, avoid shaking and deformation, and maintain the stability of the overall structure of the floor. This not only improves the bearing capacity of the floor, but also reduces the damage caused by loose structure.

5.2 Reduce maintenance frequency and cost

Effective Prevent loose floor screws reduces the frequency of floor maintenance caused by loose screws, avoids large-scale replacement and repair, saves maintenance costs, and improves economic benefits.

5.3 Enhance safety of use

The stable floor structure avoids tripping and sliding accidents, and ensures the safety of residents and users. Especially in public places and high-frequency use environments, anti-loosening measures are particularly important.

6. Precautions for users in actual applications

6.1 Choose a suitable installation environment

Before installation, ensure that the environment is dry and clean to avoid excessive humidity and impurities affecting the fastening effect. At the same time, reasonably control the construction temperature to reduce the adverse effects of thermal expansion and contraction of materials.

6.2 Avoid over-tightening or under-tightening

Over-tightening can cause screw breakage or wood crushing, while under-tightening will not achieve the expected anti-loosening effect. It is recommended to use professional torque tools to adjust the tightening force according to the material and screw specifications.

6.3 Regular professional inspections

It is recommended to hire professionals to regularly inspect floor screws to detect loosening problems in a timely manner and take remedial measures to ensure the long-term stability of the floor.

7. Future Outlook

7.1 Continuous breakthroughs in new materials and technologies

In the future, nanomaterials and smart materials will play a greater role in screw manufacturing, achieving higher strength and intelligent response. The introduction of bio-based environmentally friendly materials will also promote the development of green buildings.

7.2 Combination of green environmental protection and sustainable development

Anti-loosening technology will be deeply combined with environmental protection concepts to reduce construction waste and harmful chemical emissions and achieve sustainable development goals.

7.3 Development of intelligent maintenance and remote monitoring technology

Smart sensors are combined with cloud platforms to achieve remote monitoring of floor status and maintenance warnings, providing users with convenient and scientific maintenance management services.

8. Conclusion

Prevent loose floor screws is not only the basis for ensuring the stability and safety of the floor, but also an important part of improving the building quality and user experience. Through scientific material selection, reasonable installation process and advanced technology application, many problems caused by loose floor screws can be effectively avoided. In the future, with the continuous advancement of technology and the application of intelligent means, floor maintenance will be more efficient, safe and environmentally friendly. It is hoped that users and construction personnel will attach great importance to the work of Prevent loose floor screws and jointly create a more stable and safe living and use environment.