1. What are thin line staples?

Definition and core characteristics

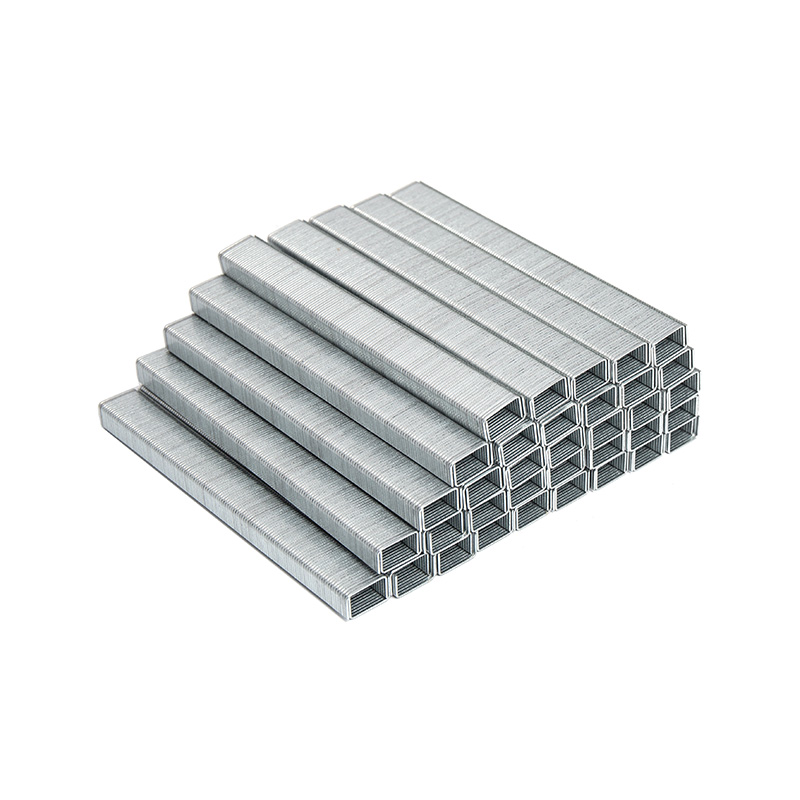

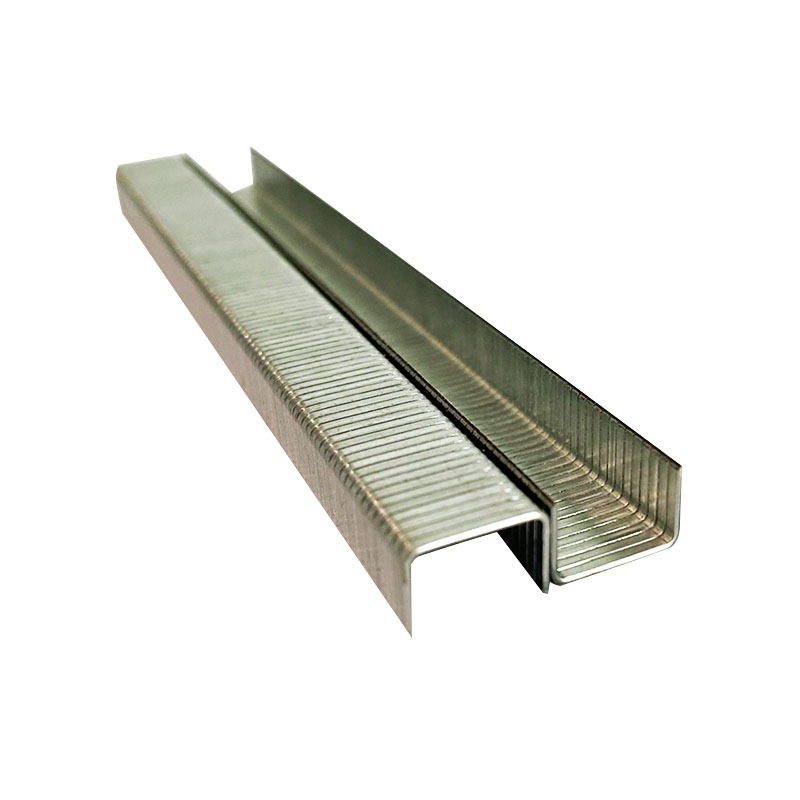

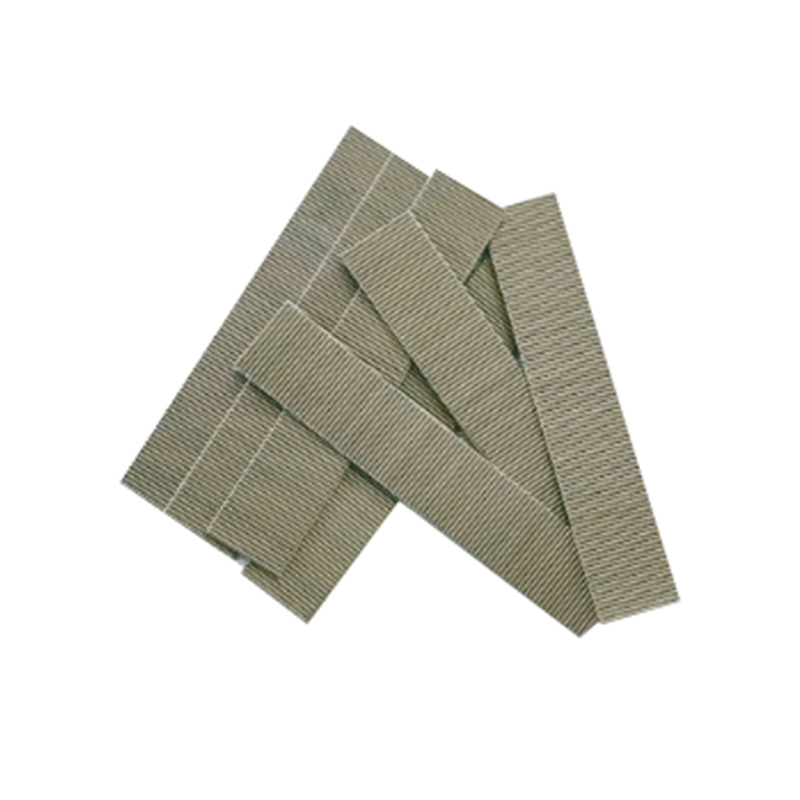

- Thin line staples are fastening elements with a narrower crown width and finer wire gauge compared to standard heavy-duty staples.

- These staples are engineered for minimal visibility, reduced damage to delicate substrates, and clean finishing in applications where aesthetics matter.

Why they differ from standard staples

- Standard staples often prioritise sheer holding strength; thin line staples prioritise subtlety and finish.

- Using finer wire and narrow crown means less substrate damage (e.g., splitting veneers) and fewer visible staple heads.

2. Key factors when selecting thin line staples

Wire gauge, crown width and leg length

When you ask “how to choose thin line staples gauge and crown width”, you must consider three interdependent dimensions:

- Wire gauge: higher gauge = thinner wire = less visible, less substrate damage.

- Crown width: narrower crown = smaller footprint; suits finish work.

- Leg length: must correspond to thickness of materials being joined — too short = poor clinch, too long = protrusion or blow-through.

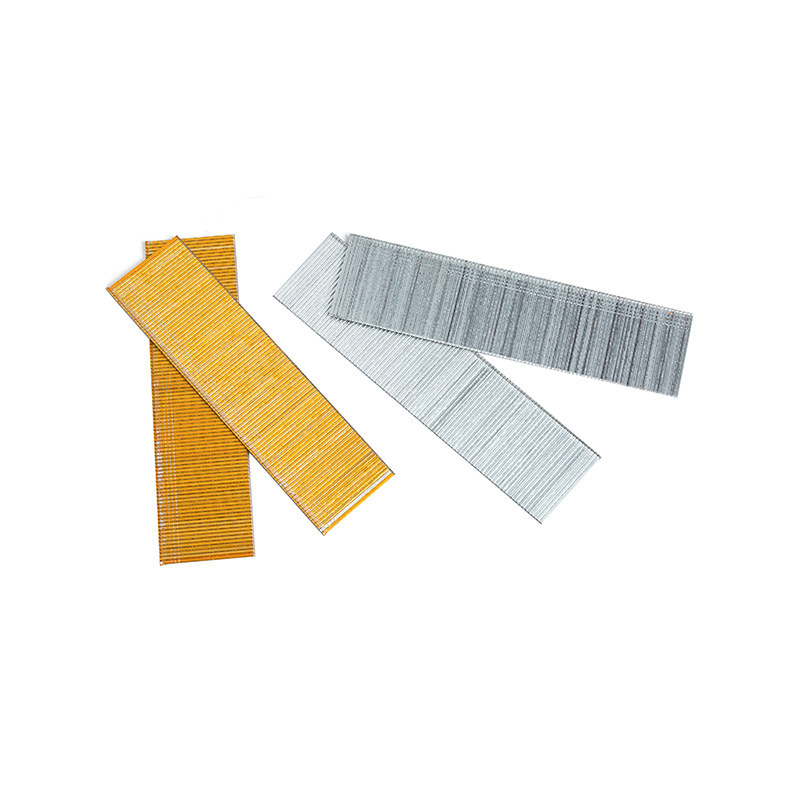

Material, finish and environment considerations

- Choose stainless steel or galvanised finishes for moisture-prone or outdoor environments to prevent corrosion.

- Interior decorative applications may allow plain steel fine-wire staples, since the visual finish is critical and corrosion risk is low. :contentReference[oaicite:4]{index=4}

- Tool compatibility: ensure stapler supports the chosen crown width and gauge; mismatches can lead to jams or poor clinch.

3. Primary applications of thin line staples

Upholstery and furniture trim

This application cluster directly links to the keyword “thin line staples for upholstery applications” and “thin line staples narrow crown furniture trim”.

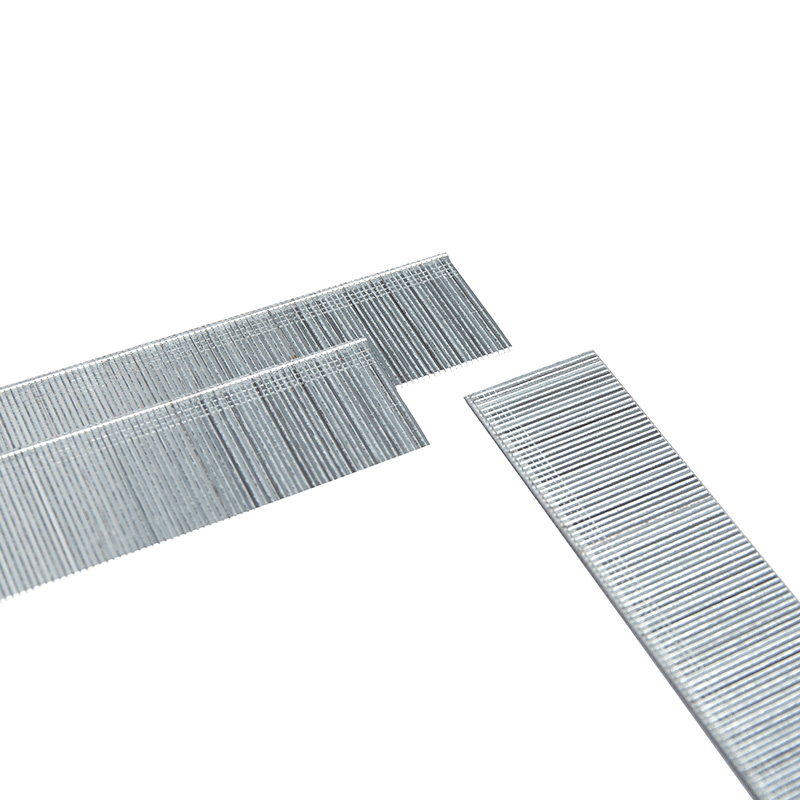

- In furniture upholstery or decorative trim, you often need fasteners that are discreet and minimise surface blemishes.

- Thin line staples allow attachment of fabric, foam or thin veneer without visible staple heads, reducing puckering or tear-through.

Packaging, veneer, decorative trim

- Thin line staples are ideal when fastening thin cardboard, decorative panels or moldings: the reduced crown area means less visible distortion and cleaner finish.

- Also used in archival or paper-based assemblies where minimal intrusion is required.

4. Comparing to other staple types: thin line staples vs narrow crown staples

Major differences

Although both types are used for less visible fastening, there is a subtle but important difference.

| Thin line staples | Narrow crown staples |

| Fine (higher) wire gauge, very narrow crown, designed for minimal visibility. | Narrow crown (smaller footprint) but wire gauge may vary; strength can be higher. |

| Prioritises subtle finish and minimal substrate damage. | Prioritises narrow contact area; may still use thicker wire for strength. |

| Best for finish upholstery/fabric/veneers. | Better for constrained areas needing moderate strength. |

This directly addresses “thin line staples vs narrow crown staples difference”.

Which type to choose for which job

- If your priority is minimal visibility and you’re working with delicate materials (thin fabric, veneer, decorative trim), go with thin line staples.

- If you need a clean, narrow footprint but higher holding power (e.g., heavier sub-materials, more load), a narrow crown staple with thicker wire may suit better.

5. Why choose a reliable manufacturer for thin line staples

Export and supply chain considerations

If you are sourcing from China or for export, the term “thin line staples manufacturer in China export” becomes relevant.

- Look for a manufacturer with import & export rights, professional production capabilities, and a full product range (from industrial nails to specialized staples).

- Our company, Zhejiang Tianying Hardware Co., Ltd., established in 2017 (original factory had 21 years’ history) and located in Anji within the Yangtze River Delta economic zone — traffic is very convenient.

- The company is a professional collective of research, design, production and sales; product range includes industrial nails, pneumatic nails, straight gun nails, bed-net clip code nails, C nails, home nails, decoration wall nails, fiberboard nails — demonstrating broad expertise.

- The company has self-management import and export rights, always adhering to the “quality of survival, quality of development, quality to benefit” policy — dedicated to serving customers.

Quality assurance and how Zhejiang Tianying fits your needs

- By selecting a manufacturer like Zhejiang Tianying, you ensure strict production control, traceability and consistent supply of high-quality thin line staples.

- The supply chain within the Yangtze River Delta region benefits from logistical efficiency, making export smoother.

- Detailed selection (gauge, crown, length, finish) can be customised to your needs, supported by the manufacturer’s experience in fastener industry.

6. Conclusion & best practices

Summary of key take-aways

- Thin line staples are distinct in their fine wire and narrow crown design, suited for subtle fastening where aesthetics and minimal substrate damage matter.

- Selecting the correct gauge, crown width, leg length and material finish is essential for optimal performance.

- Applications include upholstery, decorative trim, veneer work, packaging and other finish-sensitive tasks.

- Understanding the difference between thin line staples and narrow crown staples helps you choose the right tool for the job.

- Choosing a reliable manufacturer — such as Zhejiang Tianying Hardware Co., Ltd. — supports quality, consistency and export readiness.

Checklist for choosing and using thin line staples

- Measure material thickness and determine leg length required.

- Select wire gauge appropriate to substrate sensitivity (higher gauge for delicate materials).

- Choose crown width that minimises visibility but suits tool compatibility.

- Check material/finish for environment (indoor vs outdoor, corrosion risk).

- Test drive a few staples on scrap material to ensure clinch and finish quality.

FAQ

- Q1: What material types are commonly used for thin line staples?

A: Common materials include plain steel fine-wire for interior dry applications, galvanized steel or stainless steel for moisture or outdoor use. - Q2: Can I use thin line staples with any staple gun?

A: Not always — you must check tool compatibility for crown width, wire gauge and leg length. Mismatch may lead to jams or poor clinch. - Q3: What is the main benefit of using thin line staples over standard heavy-wire staples?

A: The key benefit is reduced visibility and less substrate damage (e.g., minimal splitting in veneers, less tearing in fabrics) while still providing adequate hold for finish work. - Q4: When should I choose narrow crown staples instead of thin line staples?

A: If you need a narrow footprint but also higher holding power (thicker wire) for heavier loads or thicker materials, narrow crown staples may be more appropriate. The comparison table above helps clarify. - Q5: What should I verify when sourcing thin line staples from a manufacturer?

A: Ensure the manufacturer has export rights, clear specification control (gauge, crown width, leg length, finish), consistent quality policy, and logistic convenience — for example, Zhejiang Tianying Hardware Co., Ltd. offers these assurances.