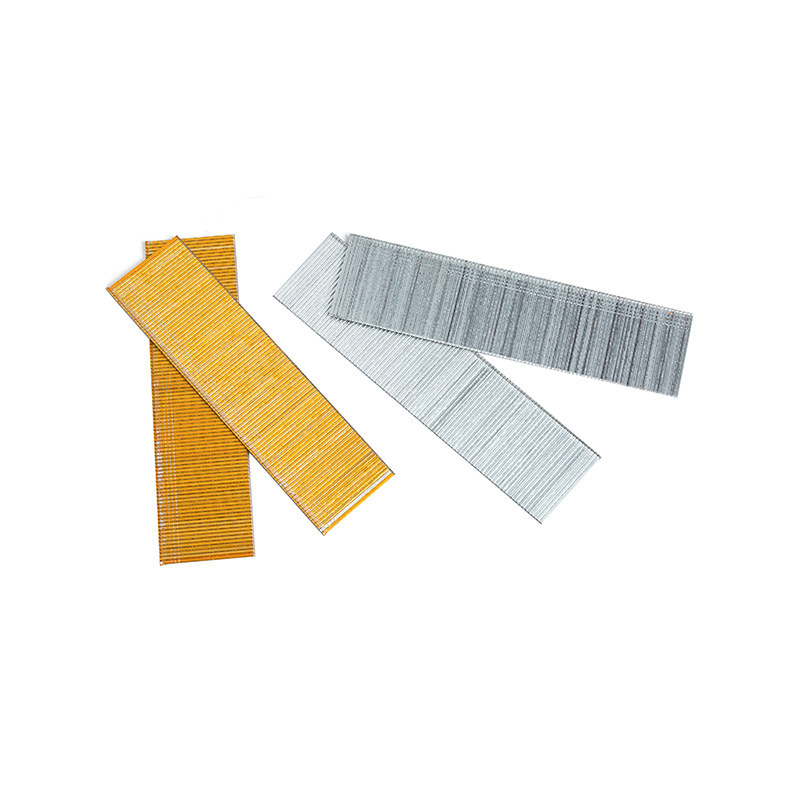

1. Reinventing Structural Fastening: The Strength Behind Steel Galvanized Staples

1.1 High-Strength Steel: The Backbone of Secure Fastening

Steel Galvanized Staples are engineered using premium-grade high-strength steel that offers exceptional tensile and compressive resistance. This material advantage allows the staples to endure substantial external force without bending, cracking, or breaking, providing long-lasting structural integrity across a wide range of applications.

1.2 Pressure Distribution for Maximum Holding Power

The mechanical properties of high-strength steel allow the staples to effectively distribute applied stress across a larger surface area. This prevents the formation of weak points and reduces the likelihood of deformation under pressure, making them highly suitable for heavy-duty use in construction, manufacturing, and load-bearing structures.

1.3 Reliable Performance Under Continuous Load Conditions

In environments where constant force or vibration is present, such as industrial assembly lines or structural frameworks, Steel Galvanized Staples maintain consistent performance without loosening or compromising the joint. Their superior holding power significantly minimizes the risk of failure over time, ensuring long-term safety and reliability.

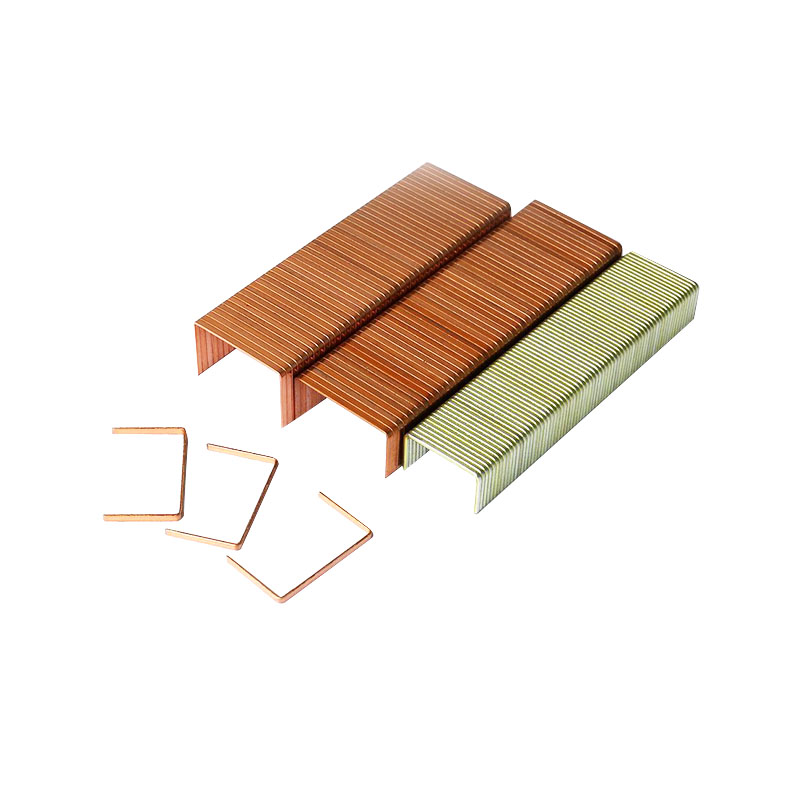

2. Engineered for Durability: Long-Term Stability in Harsh Conditions

2.1 Outperforming Conventional Staples in High-Load Environments

Compared to low-strength alternatives, Steel Galvanized Staples exhibit markedly better resistance to mechanical stress. Their superior tensile strength allows them to remain effective even in high-load applications where other staples may warp, break, or fail, thereby enhancing overall structural security.

2.2 Stability in Diverse Environmental Conditions

Steel Galvanized Staples are designed to perform in a range of environmental settings—from construction sites exposed to varying temperatures to high-humidity industrial zones. Thanks to the robust nature of high-strength steel, they maintain their grip and structural support regardless of external changes in heat, cold, or moisture.

2.3 Sustained Load Support Over Time

These staples are built for endurance. Their high fatigue resistance means they can bear repeated cycles of stress and load without losing effectiveness. This long-term performance capability makes them indispensable in critical structures requiring years of dependable service without frequent maintenance.

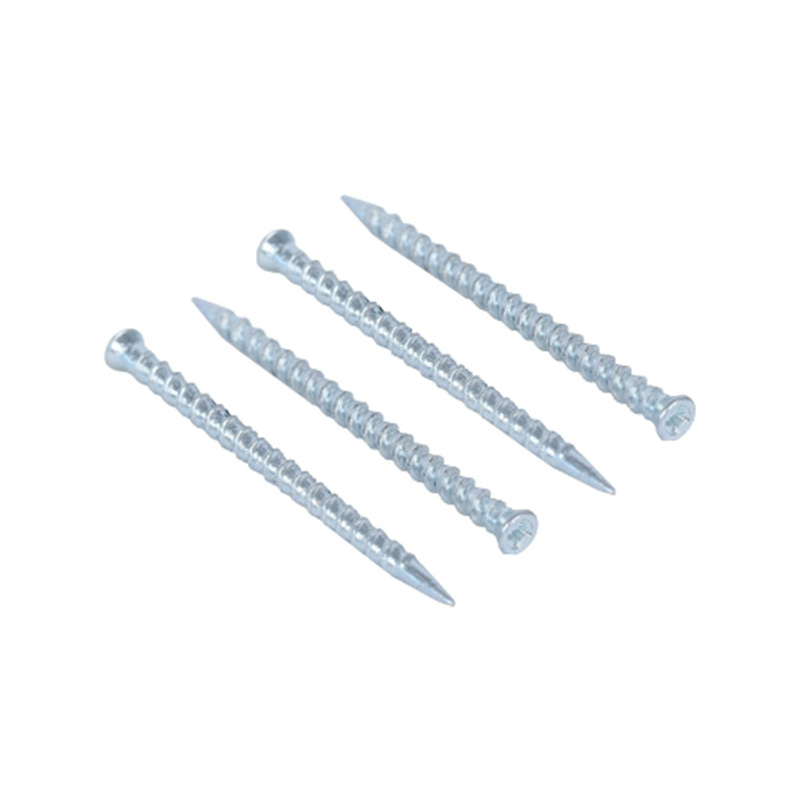

3. Smart Protection and Design: Built to Withstand Time and Corrosion

3.1 Galvanized Surface: A First Line of Defense Against Corrosion

Each staple is coated with a protective layer of zinc through the galvanization process. This barrier shields the steel from moisture, chemicals, and atmospheric elements, effectively preventing rust and corrosion. The result is an extended service life and reduced maintenance in environments like coastal areas, factories, or chemically active zones.

3.2 Lower Maintenance, Higher Cost Efficiency

The anti-corrosion properties reduce the need for frequent replacements or structural repairs due to rust-related failures. For businesses and contractors, this means fewer disruptions, lower long-term costs, and a more efficient resource allocation during the lifespan of the project.

3.3 Designed for Extreme Load-Bearing Applications

Precision engineering and robust material choice enable Steel Galvanized Staples to withstand extreme mechanical loads. Whether securing heavy machinery panels or supporting structural frames, these staples offer unparalleled durability. Their performance under extreme strain helps avoid system failures, contributing to greater safety and productivity on the job site.